Website:

FAFNIR

Website:

FAFNIR

Group: Gilbarco Veeder-Root

Catalog excerpts

The SEPARIX syste m i s an alar m syste m wh i ch m on i tors the th i ckness of the layerof o i l or l i ght l i qu i d occurr i ng i n a l i ght l i qu i d separator (e . g . o i l separator) . A SEPARIX syste m conta i ns the o i l separator sensors SEPARIX-C H or SEPARIX-C Land the m easur i ng transducer SEPARIX-ControlC . The m easur i ng transducer i s connected to an o i l separator sensor and i s des i gnedto supply i t w i th power and to analyse s i gnals . The sensors trans mi t a s i gnal to the connected m easure m ent analys i s un i t i f thelayer of o i l or l i ght l i qu...

Open the catalog to page 3

The SEPARIX system is designed to monitor the thickness of the layer of lightliquid occurring in light liquid separators. Please use the system for this purpose only. The manufacturer shall not be liable for any form of damage resulting from improper use!The measuring transducer and the oil separator sensors were developed,manufactured and tested in accordance with state-of-the-art technology, and recognized safety rules and regulations. Nevertheless, hazards may arise from the use of the system. Therefore, please observe the following safety instructions:Do not make any changes, add...

Open the catalog to page 4

corrugated tube switching point Fig. 1a: Dimensions SEPARIX-CH Fig. 1b: Dimensions ֖ SEPARIX-CL SEPARIX-C and SEPARIX-Control CPage 5/23 >

Open the catalog to page 5

When installing the oil separator sensors, observe the followingsafety instructions:Installation may only be performed by trained personnel observingall the applicable safety regulations. This also applies to the local safety regulations and accident prevention regulations notmentioned in these operating instructions.ՕThe sensors may be installed in the potentially explosive Zone0.Observe all the relevant explosion protection regulations (VDE andall local installation regulations).The sensors must be de-energised.ՕThe sensors must not be used in high-flow, non-conductive liquids(e.g. in...

Open the catalog to page 6

When operating in potentially explosive atmospheres, the extensioncable used must not exceed the maximum permissible capacitance or inductance (see instructions for the measuring transducer, page 10). The wiring to the measuring transducer consists of 3-core cable (3x0.5mm > 2 )(preferably blue cable for applications in potentially explosive atmospheres). In order to connect the sensor to the measuring transducer, pleaseobserve the installation instructions for SEPARIX-ControlC in thismanual or appropriate separate instructions concerning a different measuring transducer. Proper functioning...

Open the catalog to page 7

When servicing the oil separator sensors, observe the followingsafety instructions:Maintenance may only be performed by trained personnel observingall the applicable safety regulations. This also applies to the localsafety regulations and accident prevention regulations notmentioned in these operating instructions.ՕThe sensors may be installed in the potentially explosive Zone0.Observe all the relevant explosion protection regulations (VDE and all local installation regulations).The sensors must be de-energised.ՕNever use dry cleaning cloths but always ones which are moist inorder to avoid...

Open the catalog to page 8

Explosion protection:II1GEExia IIBT5Certificate:TV03ATEX2368XProtection category, housing:IP 68 Dimensions:SEPARIX-CH:28mm x 728mmSEPARIX-CL:28mm x 195mmCable length:SEPARIX-CH:4.5mSEPARIX-CL:5 mAmbient temperature:-20 ܰ C to +70 C-20 а C to +60 C(potentially explosive atmosphere)Medium temperature:0 а C to +70 C0 а C to +60 C(potentially explosive atmosphere)Connection data:Voltage:U > i Тɤ 15VDCCurrent:I > i ≤ 30mAPower input:P > i ≤ 100mW > SEPARIX-C and SEPARIX-Control CPage 9/23 size="-1">

Open the catalog to page 9

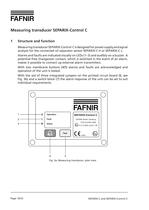

Fig. 3a: Measuring transducer, plan view SEPARIX-C and SEPARIX-Control CPage 10/23 >

Open the catalog to page 10

SEPARIX-C and SEPARIX-Control CPage 11/23 >

Open the catalog to page 11

Fig. 3b: Jumpers and switches on the printed circuit board (inside the lid) > SEPARIX-C and SEPARIX-Control CPage 12/23 >

Open the catalog to page 12

When putting the measuring transducer into operation, observe thefollowing safety instructions:Installation may only be performed by trained personnel observingall the applicable safety regulations. This also applies to the local safety regulations and accident prevention regulations notmentioned in these operating instructions.ՕThe measuring transducer must not be installed within thepotentially explosive zone.Wiring work may only be carried out with the equipment in de-energized condition. Install the measuring transducer according to the wiring diagram on the insideof the lid of the unit...

Open the catalog to page 13

If the o i l separator sensor reports an alar m , the red LED " Alar m" flashes on the m easur i ng transducer . If there i s a fault (fault i n the sensor connected), the yellow " Fault " LED flashes . In such a case, proceed as follows : 1 . Press Alar m button . The yellow/red LED now re m a i ns l i t cont i nuously i nstead of flash i ng; the fault/alar m has been acknowledged . If switch 1 on the "Options" switch block was used to activateautomaticalarm repetition, the alarm will have to be acknowledgedagain 24hours later. 2 . El imi nate the cause of the fault or alar m. The...

Open the catalog to page 14

SEPARIX-C and SEPARIX-Control CPage 15/23 >

Open the catalog to page 15

SEPARIX-C and SEPARIX-Control CPage 16/23 >

Open the catalog to page 16

SEPARIX-C and SEPARIX-Control CPage 17/23 >

Open the catalog to page 17

SEPARIX-C and SEPARIX-Control CPage 18/23 >

Open the catalog to page 18

SEPARIX-C and SEPARIX-Control CPage 19/23 >

Open the catalog to page 19

As of: 12.20034.1Mode of operationThe oil separator sensor is used in light liquid separators (e.g. oil or grease separators) and serves the purpose of detecting the separation layer between water and light liquid. When the layer thickness of the light liquid reaches the switching point of the sensor (40 mm above the sensor tip), an alarm signal is produced via the respective measuring transducer.The sensor operates according to the capacitive measuring principle. For thepurpose of separation layer detection this sensor exploits the difference between the relative dielectric constant of...

Open the catalog to page 20

4.3Operating instructionsWithin the scope of regular maintenance work on the light liquid separator, the oil separator sensor must be properly cleaned thoroughly using a moist cloth. The risk of electrostatic charges due to high-flow, non-conductive liquids (e.g. in pipelines, stirring tanks) must be avoided. Grease-dissolving cleansing agents can be used to remove any firmly clinging grease or oil residues.Prior to putting into service, all devices must be checked with respect to correctconnection and proper operation. The electrical power supply, including the supply of the downstream...

Open the catalog to page 21All FAFNIR catalogs and technical brochures

-

TORRIX M12 MOBILE

2 Pages

-

TORRIX XTS

2 Pages

-

TORRIX 6

1 Pages

-

LPG Sensors

8 Pages

-

SEPARIX

8 Pages

-

Process Automation

28 Pages

-

O²-PID

4 Pages

-

COMS Leaflet

4 Pages

-

VAPORIX Flow and Control

40 Pages

-

Wallmounting Typ 907

4 Pages

-

QE 200

4 Pages

-

UM 2.1/2.2/2.3

20 Pages

-

TORRIX HART

28 Pages

-

TORRIX RS485 Modbus

16 Pages

-

TORRIX M12

40 Pages

-

FAFNIR Hart Setup

9 Pages

-

LS 300 / 500

7 Pages

-

76 A / NB 220

5 Pages

-

76 / NB 220

2 Pages

-

SECON-X

4 Pages

-

PRESSURIX

12 Pages

-

Insite360

4 Pages

-

Plugs

12 Pages

-

UM 2.1/UM 2.2/UM 2.3

20 Pages

-

TORRIX-HART

28 Pages

-

DIVELIX

8 Pages

-

CONDURIX-HART

28 Pages

-

CONDURIX

24 Pages

-

VAPORIX

12 Pages

-

VISY-X

24 Pages

-

Accessories

3 Pages

-

VISY-Command Web

4 Pages

-

VISY-Reed

4 Pages

-

VISY-RF

2 Pages

-

VISY-Stick

15 Pages

-

VISY-TD Display

2 Pages

-

VISY-View Touch

2 Pages

-

VPI - VISY-Power Interface

1 Pages

-

TORRIX

10 Pages

-

TORRIX CI

1 Pages

-

TORRIX RS485

3 Pages

-

UM-X Transducer

3 Pages

-

TEMPERIX

8 Pages

-

HPH Ex d

3 Pages

-

VISY-Monitor

2 Pages

-

VISY-Input VISY-Output

4 Pages

-

VISY-Command

5 Pages

-

LPG-Sensoren

8 Pages

Archived catalogs

-

2019 VISY-Stick Flex

2 Pages

-

2016 VISY-Stick Flex

2 Pages

-

VISY-X LON

10 Pages

-

VAPORIX Flow/Control

32 Pages

-

VISY-Setup V 3.1.0

40 Pages

-

VISY-Setup V2.10

42 Pages

-

VISY-View

24 Pages

-

VISY-Stick and VISY-Command

24 Pages

-

Overfill Prevention (GWG)

12 Pages