Website:

Facet International

Website:

Facet International

Group: Clarcor

Catalog excerpts

copyright 2006 www.facetinternational.com Definition Liquid filtration is the removal of solids from liquids by flowing the contaminated liquid through a filter media that will retain the solids and allow only clean product to pass through. Filtration Function Using a surface filter medium to remove a volume of solids from a liquid requires that the medium should contain uniform pores smaller than the smallest particle to be removed. It should also be strong enough and possess sufficient area to hold the required volume of solids. If a depth-type medium is used, the medium must contain an infinite number of small, irregular, continuous passages which give the solids a tortuous path to travel through. A depth medium of proper density will stop essentially all solids above a specified size. The medium selected must withstand the manufacturer’s required maximum allowable pressure drop and provide a margin of safety to cover both inadequate maintenance and line pressure surges commonly found in systems as a result of stops and starts. Facet uses both types of media in its product range. General Applications • Removing solids that may damage the aesthetic appearance of a product. Example: Solids in paint, bleach, liquid soaps, vinegar, plastic resin for use in plastic extrusion products. • Removing solids which could affect chemical reaction of a product. Example: Catalyst fine in a refining process. • Removing solids that could damage operating equipment. Example: Abrasive contaminant in hydraulic and lubricating oils. • Removing solids that could affect a finished production item. Example: Contaminant in grinding and cutting oil of production equipment. • Removing solids that could in some way affect the health of operating personnel. Example: Radioactive waste in primary coolant system on boiling water reactors and clean-up water in water reactor system. Proper Selection Of Filters Selection of media and vessel design determine the filter flow rate, dirt holding capacity, particle-size removal in one pass, overall cost of operation and initial investment. Replaceable cartridge-type filters have wide usage and can be used in most any application. The two most important factors to consider when determining whether to use a replaceable cartridgetype filters are the concentration of the solids to be retained by the filter and the required degree of filtration. Cost Of Filtration One realistic method of determining the “true cost” of filtration is the cost per pound of solids removed from a liquid. The four factors that make up this “true cost” are: 1. Cost of media (cartridges) 2. Cost of service parts (gaskets, etc.) 3. Cost of maintenance labor 4. Cost of downtime to service or maintain (value of lost production) By totaling these four factors, determine a unit base as cost per pound, per gallon, per barrel, per year, etc. Although the cost of new equipment may vary, the “true cost” to the user is based on a cost per pound of solids removed. However, the achievement of a specific standard of quality cannot be measured by cost alone and this is the true value of a filter. Capabilities Today, more than ever, quality-conscious customers expect, and efficient plant operations dictate, the removal of solid contaminants from liquid products or processes. Filtration of particles too small for the eye to detect is essential to protect and improve quality, assure customer acceptance, prevent malfunctioning of equipment and reduce wear on machinery. Facet filtration equipment has been designed for easy maintenance. The many easy service features reduce downtime and labor cost in maintaining equipment. These costs are important in evaluating both initial and future operational expenses. With nearly 60 years of constant research, product development and quality controlled production, Facet offers you maximum dependability, quality, innovative engineering and service. Liquid Filtration General Description I-101 Facet I-1 Rev 04-2006.indd 1 2/14/2007 5:07:43 PM

Open the catalog to page 1

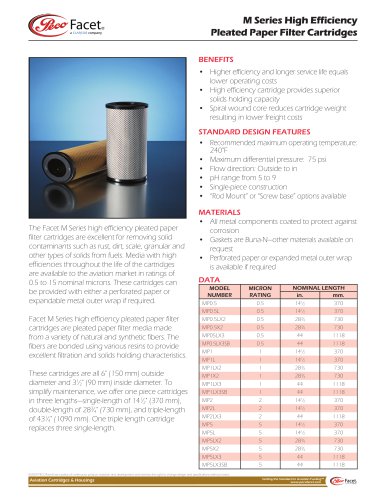

copyright 2006 www.facetinternational.com DESCRIPTION Facet M Series high efficiency pleated paper filter cartridges are designed to effectively remove solid contaminants such as rust, dirt, scale, granular and other types of solids. These cartridges known as the MP Series high efficiency filter cartridges are constructed to meet the demanding requirements of the industrial filter market. Media with high efficiencies throughout the life of the cartridges are available in ratings of 0.5 to 75 microns. The filtration of potable liquids is not recommended with this series of filter cartridges....

Open the catalog to page 3

copyright 2006 www.facetinternational.com CIF Series High Efficiency Pleated Paper Coreless Filter Cartridges DESCRIPTION The patented Facet CIF Series high efficiency coreless pleated paper filter cartridges are designed to effectively remove solid contaminants. The filtration of potable liquids is not recommended with this series of filter cartridges. These cartridges are constructed to meet the demanding requirements of the industrial filter market. Media with high efficiency throughout the life of the cartridge is available in ratings of 0.5 to 25 microns. We recommend replacing...

Open the catalog to page 7

copyright 2006 www.facetinternational.com CIF Series Center Tube Kit Installation Instructions INSTALLATION INSTRUCTIONS TO INSTALL THE CIF CENTER TUBE 1. Remove existing filter cartridge. NOTE: Leave center rod in position. 2. Identify bottom of center tube. Only the top of center tube will accept top adaptor (3). 3. Place center tube assembly with the bottom guide (5) down making sure it is properly aligned on the existing cartridge adaptor. 4. For kit numbers CIF2, CIF3 and CIF4, be sure to properly align centering guide (4) over center rod. 5. Slide top adaptor (3) over center rod and...

Open the catalog to page 9

copyright 2006 www.facetinternational.com DESCRIPTION Facet FI Series filter cartridges provide efficient and economical filtration of fluids in a wide range of applications. These industrial filter cartridges are used for removal of particulate from a broad range of products where nominal filtration is required. Facet FI Series filter cartridges provide a large surface area for maximum dirt holding capacity, high flow rates and low initial pressure drops. The normal flow direction is outside to inside, however, specially designed cartridges are available for reverse flow. FI Series...

Open the catalog to page 11All Facet International catalogs and technical brochures

-

FG Model 2"

1 Pages

-

CAA Model 5

2 Pages

-

Model MPI

1 Pages

-

Model M

1 Pages

-

Model FA

1 Pages

-

PF-CDPI

1 Pages

-

JetGard?

4 Pages

-

Clay treater cartridges

3 Pages

-

Fuel Monitors

21 Pages

-

F Series potabilizers

2 Pages