Catalog excerpts

Specifications subject to change without notice or incurring obligation 15 6-29-05 15.1 VTR-1 Features & Benefits • Low Cost Simple design results in low cost. No moving parts to wear means no maintenance costs. No maintenance means no down time costs. • Adjustable Control vacuum level by adjusting air supply pressure. • Compact Allows you to locate the vacuum generator at the point of application for highest efficiency. • Quiet No vanes, pistons or motors. • Safe No moving parts, safe in hazardous atmospheres. • Efficient Air consumption: 4.8 SCFM @ 80 psi inlet. Vacuum level: 28 in. Hg @ 80 psi inlet. Standard Specifications Glossary of Terms • Air Consumption The volume of compressed air, per unit time, required to operate the vacuum generator; measured in standard cubic per minute (SCFM). • Air Supply Pressure Pressure of the compressed air at the supply inlet of the vacuum generator; measured in pounds per square inch (psi). • Time of Evacuation The time required to evacuate a given system from atmospheric pressure to a specified negative pressure (vacuum level). • Vacuum Vacuum exists when atmospheric air is removed from a system, resulting in less pressure within the system than the atmospheric pressure outside the system. • Vacuum Flow The rate at which atmospheric air moves out of a system is defined as the vacuum flow rate and is expressed in standard cubic feet per minute (SCFM). • Vacuum Level The level of negative pressure is defined as vacuum level and expressed in inches of Mercury (in. Hg.). Model VTR-1 Materials: Aluminum, black anodized and Brass Weight: 2.1 oz. 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 10 20 30 40 50 60 70 80 Vacuum Level in. Hg Air Supply Pressure, psig 1 1.5 2 2.5 3 3.5 4 4.5 5 10 20 30 40 50 60 70 80 Air Consumption SCFM Air Supply Pressure, psig 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 0 28.4 44.6 87.8 Time of Evacuation for 1 Cu. Ft. in. Hg Time, Seconds 80 psi Air Supply Pressure The VTR Vacuum Generator produces high quality vacuum, from shop air, that can be used for applications such as suction cups for parts handling, chamber evacuation, and 3.33 countless others. 3/4 Hex 1.06 1/4 NPT Exhaust Outlet 1/8 NPT Air Supply Inlet 1/8 NPT Vacuum Inlet Vacuum Generator

Open the catalog to page 1All FABCO-AIR catalogs and technical brochures

-

Swing Clamp Cylinders

4 Pages

-

PNEUMATIC ROTARY ACTUATORS

8 Pages

-

Pneumatic Linear Slides

82 Pages

-

NFPA Air Cylinders

16 Pages

-

F-Series Air Cylinders

64 Pages

-

Global Series ™ Air Cylinders

48 Pages

-

FRB Series Rotary Actuators

8 Pages

-

FKHT Series

4 Pages

-

FVH-16

1 Pages

-

H-Series Air Cylinders

32 Pages

-

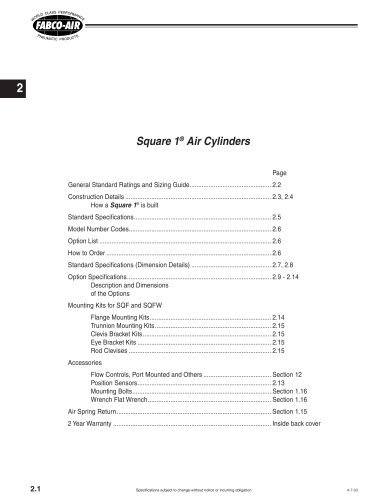

Square 1® Air Cylinders

15 Pages

-

Specialty & Control Valves

16 Pages

-

FKHQ Gripper

4 Pages

-

Hi-Power Cylinder section of CV9

10 Pages

-

NFPA Cylinders

8 Pages

-

Square 1 Series section of CV9

32 Pages

-

FGYB & FGYR Series

12 Pages

-

FJU Series Catalog

8 Pages

-

FKA Gripper Catalog

4 Pages

-

Gripper Catalog

24 Pages

-

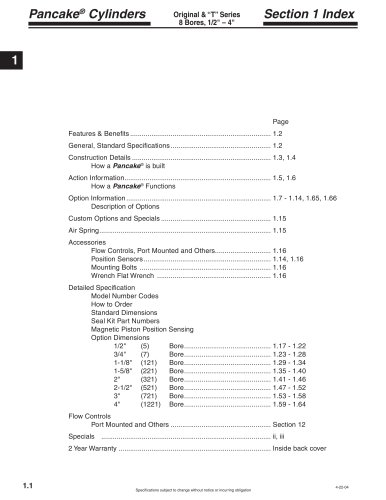

Pancake® II Catalog

28 Pages

-

Air-Oil Tanks

4 Pages

-

Multi-Power ® Air Presses

12 Pages

-

FKHT Gripper Catalog

4 Pages

-

FDH Finger Slide

8 Pages

-

FGXS Air Slide Table Catalog

4 Pages

-

Master Catalog

200 Pages

-

FDF Twin Rod Catalog

4 Pages

-

FAE Series ISO-6432 Catalog

12 Pages

-

FDXS Twin Rod Catalog

8 Pages

-

Square Pancake II Catalog

20 Pages

-

Micro-Mist Separator

1 Pages

Archived catalogs

-

Pneumatic Grippers

24 Pages