Catalog excerpts

IMPROVE PERFORMANCE AND REDUCE THE COSTS OF YOUR Engineers no longer have to accept conventional gripper design flaws. FABCO-MR A member of Festo Group

Open the catalog to page 1

A member of Festo Group Pneumatic grippers are an integral part of pick-and-place, material transfer and part ejection applications in many industries, but many designs come with limitations. Conventional grippers often present mounting, repair and functional difficulties that can cause maintenance and performance problems. Fabco-Air has developed a series of grippers that has only three moving parts. This novel design offers greater functionality and improved mounting versus conventional grippers — without the usual difficulties. A SIMPLE DESIGN APPROACH USES JUST THREE MOVING PARTS SPG...

Open the catalog to page 2

A member of Festo Group Four dowel pins keep the porting block perfectly aligned with the cylinder blocks. Eight linear bearings guide four pistons through the entire length of the gripper body. This construction maintains a centering accuracy of 0.002 inch with 0.0015 inch or less of side play per jaw. IMPROVED FUNCTIONALITY, ACCURATE GRIPPING AND LESS MAINTENANCE Many traditional gripper designs are characterized by a “metal on metal” sliding gib in a “T” slot and narrow support area that can deflect and cause play. Another design limitation: The power system is typically positioned far...

Open the catalog to page 3

A member of Festo Group MOUNTING IMPROVEMENTS ADD VERSATILITY Whether you’re trying to attach tooling to a gripper jaw, attach a gripper to a mating actuator arm or replace a gripper without major adjustment and realignment, conventional gripper mounting surfaces can be problematic. To make tooling attachment easier, SPG Gripper jaws have three rows of tapped mounting holes and dowel holes for greater mounting versatility: • Straight jaws attach inexpensive blade-type gripping fingers with pockets used to grip rectangular parts. • Angle jaws have a slip-fit dowel hole and a slip-fit dowel...

Open the catalog to page 4

A member of Festo Group Slip Fit Channel machined into customer's tooling Customer's mounting surface B* Dowel Slot Detail Option "A" Center Locating Dowel Figure 6. Dowel Approach 1. Slip Fit Dowel Slot Customer's mounting surface Option "A" Center Locating Dowel Figure 7. Dowel Approach 2. The jaws close completely together against one another, establishing a gripper centerline. The dowel pin that pivots the rocker arm to establish centering also engages the tooling. That means all centerlines are the same! LESS PARTS MEAN EASY REPAIR Because SPG Grippers have only three moving parts and...

Open the catalog to page 5All FABCO-AIR catalogs and technical brochures

-

Swing Clamp Cylinders

4 Pages

-

PNEUMATIC ROTARY ACTUATORS

8 Pages

-

Pneumatic Linear Slides

82 Pages

-

NFPA Air Cylinders

16 Pages

-

F-Series Air Cylinders

64 Pages

-

Global Series ™ Air Cylinders

48 Pages

-

FRB Series Rotary Actuators

8 Pages

-

FKHT Series

4 Pages

-

FVH-16

1 Pages

-

H-Series Air Cylinders

32 Pages

-

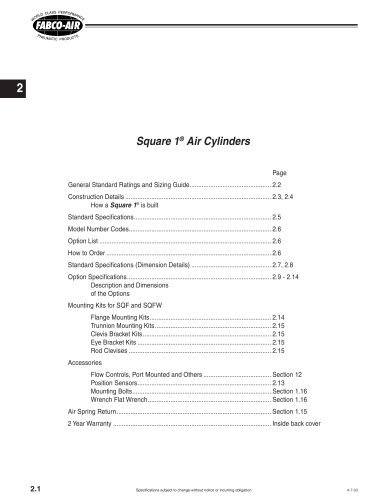

Square 1® Air Cylinders

15 Pages

-

Specialty & Control Valves

16 Pages

-

FKHQ Gripper

4 Pages

-

Hi-Power Cylinder section of CV9

10 Pages

-

NFPA Cylinders

8 Pages

-

Square 1 Series section of CV9

32 Pages

-

FGYB & FGYR Series

12 Pages

-

FJU Series Catalog

8 Pages

-

FKA Gripper Catalog

4 Pages

-

Gripper Catalog

24 Pages

-

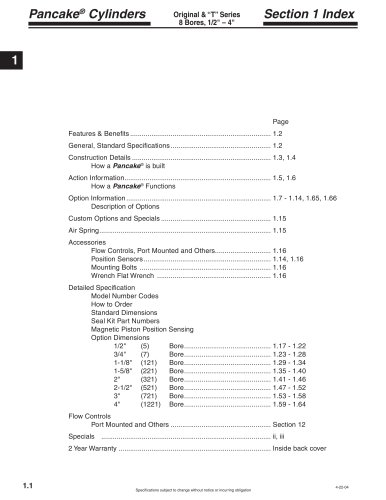

Pancake® II Catalog

28 Pages

-

Air-Oil Tanks

4 Pages

-

Multi-Power ® Air Presses

12 Pages

-

FKHT Gripper Catalog

4 Pages

-

FDH Finger Slide

8 Pages

-

FGXS Air Slide Table Catalog

4 Pages

-

Master Catalog

200 Pages

-

FDF Twin Rod Catalog

4 Pages

-

FAE Series ISO-6432 Catalog

12 Pages

-

FDXS Twin Rod Catalog

8 Pages

-

Square Pancake II Catalog

20 Pages

-

Vacuum Generator

1 Pages

-

Micro-Mist Separator

1 Pages

Archived catalogs

-

Pneumatic Grippers

24 Pages