Website:

Expansion Electronic

Website:

Expansion Electronic

Catalog excerpts

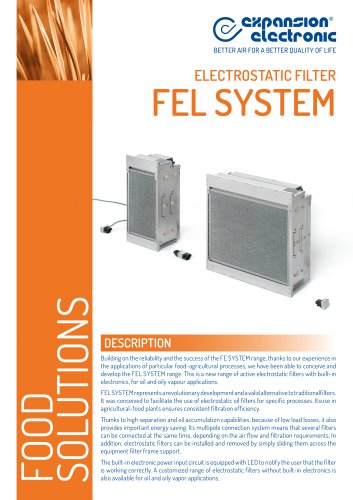

ELECTROSTATIC FILTER FOOD SOLUTIONS DESCRIPTION DESCRIZIONE Building on the reliability and the success of the FE SYSTEM range, thanks to our experience in the applications of particular food-agricultural processes, we have been able to conceive and develop the FEL SYSTEM range. This is a new range of active electrostatic filters with built-in electronics, for oil and oily vapour applications. FEL SYSTEM represents a revolutionary development and a valid alternative to traditionalfilters. It was conceived to facilitate the use of electrostatic oil filters for specific processes. Itsuse in agricultural-food plants ensures consistent filtration efficiency. Thanks to high separation and oil accumulation capabilities, because of low load losses, it also provides important energy saving. Its multipole connection system means that several filters can be connected at the same time, depending on the air flow and filtration requirements. In addition, electrostatic filters can be installed and removed by simply sliding them across the equipment filter frame support. The built-in electronic power input circuit is equipped with LED to notify the user that the filter is working correctly. A customized range of electrostatic filters without built-in electronics is also available for oil and oily vapor applications,

Open the catalog to page 1

ELECTROSTATIC FILTER FEL SYSTEM CHARACTERISTICS FEL filters are particularly suited for the abatement of polluting substances such as oily vapours and mists, with and without particulate. The main distinguishing characteristic of this filter is the bottom section of the capture blades, the shape of which has been purposely conceived to enable the dripping of high quantities of oily pollutants, with reduced formation of electric discharges between the plates. In addition, the special mechanical construction ensures, also in the presence of emulsifying oils, that no electric discharges occur...

Open the catalog to page 2

ENERGY SAVING In the active electrostatic filter FEL SYSTEM, the initial pressure drop increases slowly while the filter gets dirty. This characteristic, combined to an extraordinary capacity of pollutants accumulation, allows the filter to have a long operation time between maintenance and the other one. In a traditional pocket filter the initial pressure drop is higher than in a FEL SYSTEM, and it increases considerably during its clogging. The pocket filter must be replaced when it reaches the maximum pressure drop of 300 Pa. Comparing the FEL SYSTEM with two other different filtering...

Open the catalog to page 3

FRAME material: aluminium - PREFILTER material: metal mesh Pressure drop as a function of air flow rate (clean filter) 100 Filter clogging in g of ISO12103-A2 dust CERTIFICATIONS BSRIAJ ensemble, innover et valider Consiglio Nazionale delle Ricerche EXPANSION ELECTRONIC SRL ■ Via delle Industrie, 18 ■ 36050 Cartigliano (VI) ■ ITALY T. +39 0424 592400 ■ +39 0424 827058 ■ +39 0424 827059 ■ F. +39 0424 827061 www.expansion-electronic.com ■ info@expansion-electronic.com

Open the catalog to page 4All Expansion Electronic catalogs and technical brochures

-

Serie c

8 Pages

-

FE SYSTEM ELECTROSTATIC FILTER

16 Pages

-

C series

8 Pages

-

RAC

2 Pages

-

M series

14 Pages

-

AIR SPONGE FILTER

2 Pages

-

CP500

4 Pages

-

FCP SYSTEM

2 Pages

-

frame holder

2 Pages

-

FE SYSTEM

8 Pages

-

GRANULAR ACTIVE CARBON

2 Pages

-

LABYRINTH FILTER

2 Pages

-

carbox

2 Pages

-

FI SYSTEM

2 Pages

-

FX SYSTEM

2 Pages

-

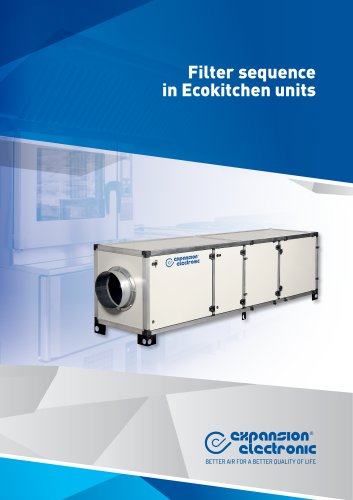

Ecokitchen

8 Pages

-

UCO600-800

2 Pages

-

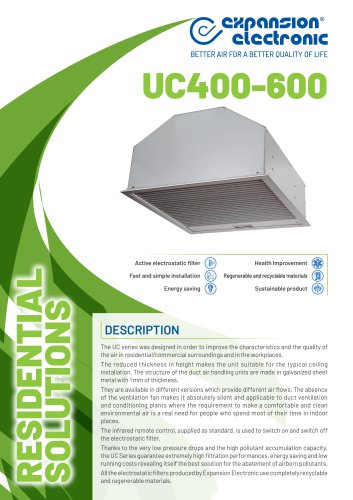

UC400-600

2 Pages

-

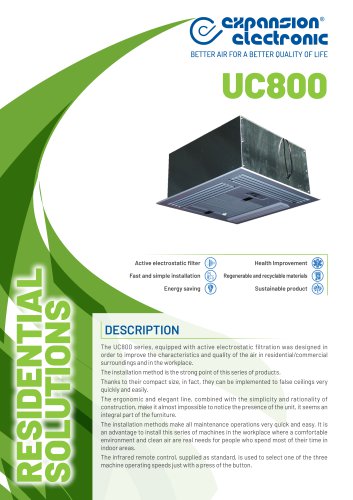

UC800

2 Pages

-

UC1200

12 Pages

-

PF METAL COMPACT

2 Pages

-

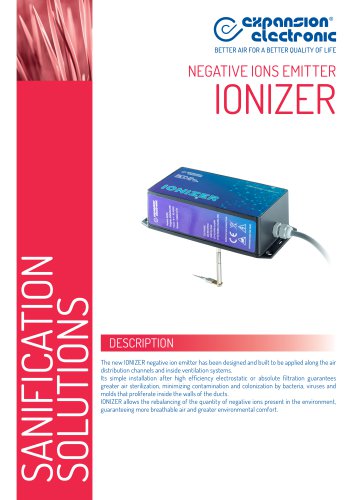

IONIZER

2 Pages

-

PROLIFE

2 Pages

-

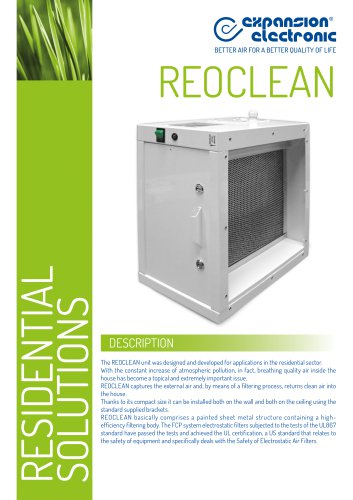

REOCLEAN

2 Pages

-

FEM

2 Pages

-

ECOLIGHT

8 Pages