Website:

EXAIR

Website:

EXAIR

Catalog excerpts

Stay up to date by visiting our website and take advantage of the information and services we didn’t have room to display in this catalog. Where you can • Chat live with our problem solving, technical expert Application Engineers • Watch product videos to learn more about the features and benefits of our engineered products • Quickly order online with a purchase order or credit card (US & Canada) • Access product presentation slides you can use to educate others • Find International Distributors all across the world Access our Knowledge Base to • Download 3D models and CAD drawings in...

Open the catalog to page 2

Terms and Conditions (U.S. and Canada Only) Terms: ICC (International Chamber of Commerce) INCOTERM 2010: Delivery Ordering: Remit to address (payments only): Tax: Technical Assistance: Warranty: * 5 Year Warranty applies to compressed air products only. A 1 Year Warranty applies to all accessories and electrically powered products. EXAIR’s Unconditional Guarantee: Copyright Restrictions: 11510 Goldcoast Dr. Cincinnati, Ohio 45249-1621 Phone Number: (513) 671-3322 Fax Number: (513) 671-3363 E-mail: techelp@exair.com Web Site: www.exair.com Net 30 days upon credit approval, Visa, MasterCard,...

Open the catalog to page 3

Vortex Tubes MOBILE VIEW Vortex Tubes Cold air to -50°F (-46°C) from your compressed air supply — with no moving parts! What Is A Vortex Tube? A low cost, reliable, maintenance free solution to a variety of industrial spot cooling problems. Using an ordinary supply of compressed air as a power source, vortex tubes create two streams of air, one hot and one cold, with no moving parts. Vortex tubes can produce: • Temperatures from -50° to +260°F (-46° to +127°C) • Flow rates from 1 to 150 SCFM (28 to 4,248 SLPM) • Refrigeration up to 10,200 Btu/hr. (2,989 Watts) Temperatures, flows and...

Open the catalog to page 4

Vortex Tubes How A Vortex Tube Works Compressed air, normally 80-100 PSIG (5.5 - 6.9 BAR), is ejected tangentially (1) through a generator into the vortex spin chamber (2). At up to 1,000,000 RPM, this air stream revolves toward the hot end (3) where some escapes through the control valve (4). The remaining air, still spinning, is forced back through the center of this outer vortex. The inner stream gives off kinetic energy in the form of heat to the outer stream and exits the vortex tube as cold air (5). The outer stream exits the opposite end as hot air (6). There is a detailed discussion...

Open the catalog to page 5

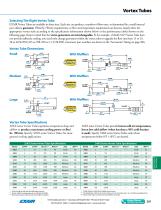

Vortex Tubes Selecting The Right Vortex Tube EXAIR Vortex Tubes are available in three sizes. Each size can produce a number of flow rates, as determined by a small internal part called a generator. If Btu/hr. (Watts) requirements, or flow and temperature requirements are known, simply select the appropriate vortex tube according to the specification information shown below or the performance tables shown on the following page. Keep in mind that the vortex generators are interchangeable. If, for example, a Model 3215 Vortex Tube does not provide sufficient cooling, you need only change...

Open the catalog to page 6

Vortex Tubes Vortex Tube Performance The Vortex Tube Performance Tables below give approximate temperature drops (and rises) from inlet air temperature produced by a vortex tube set at each cold fraction. Assuming no fluctuation of inlet temperature or pressure, a vortex tube will reliably maintain temperature within ±1°F. Pressure Supply PSIG 20 Pressure Supply Numbers in shaded area give temperature drop of cold air, °F. Numbers in white area give temperature rise of hot air, °F. Back Pressure: The performance of a vortex tube deteriorates with back pressure on the cold air exhaust. Low...

Open the catalog to page 7

Vortex Tubes Cooling Vacuum Formed Parts The Problem: A manufacturer of major appliances vacuum forms the plastic interior shell of refrigerators. The deep draw of the plastic and complex geometry left the four corners unacceptably thin. The corners would tear during assembly or bulge when insulation was inserted between the shell and exterior housing, resulting in a high rejection rate. The Solution: (4) Model 3225 Vortex Tubes were positioned to cool the critical corner areas just prior to forming the plastic sheet. By cooling these areas, less stretching of the plastic occurred which...

Open the catalog to page 8

Vortex Tubes Cooling Blow Molded Fuel Tanks The Problem: Automobile fuel tanks are blow molded, then clamped to a fixture to prevent distortion during the cooling cycle. The cooling time of over 3 minutes required for each tank created a bottleneck in the production process. The Solution: (2) Model 3250 Vortex Tubes were mounted to the cooling rack and connected to a compressed air line. Cold air produced by the vortex tubes was circulated inside the fuel tanks. Cooling time was reduced from three minutes to two minutes for each tank, improving productivity by 33%. Comment: It’s hard to...

Open the catalog to page 9

Vortex Tubes A Phenomenon of Physics The two questions we’re most often asked about the vortex tube are, “How long has it been around?” and “How does the thing work?”. Following is a brief history and theory of the vortex tube. The vortex tube was invented quite by accident in 1928. George Ranque, a French physics student, was experimenting with a vortex-type pump he had developed when he noticed warm air exhausting from one end, and cold air from the other. Ranque soon forgot about his pump and started a small firm to exploit the commercial potential for this strange device that produced...

Open the catalog to page 10

Vortex Tubes EXAIR Cooling Kits Vortex Tube Accessories and Components EXAlR Cooling Kits include a vortex tube, all generators, cold muffler, fitting, tubing and clips to duct cold air, and filter separator. Model # 3908 3930 3998 Description Cooling Kit up to 550 Btu/hr. (162 Watts), Small Size Cooling Kit up to 2,800 Btu/hr. (821 Watts), Medium Size Cooling Kit up to 10,200 Btu/hr. (2,989 Watts), Large Size Description Vortex Tube, 2 SCFM (57 SLPM), for max. refrigeration, 135 Btu/hr. (40 Watts), Small Size Vortex Tube, 4 SCFM (113 SLPM), for max. refrigeration, 275 Btu/hr. (80 Watts),...

Open the catalog to page 11All EXAIR catalogs and technical brochures

-

Summer 2023 Exair Mail 136

1 Pages

-

Spring 23 Exair Mail 135

2 Pages

-

Fall 2022 Exair Mail 133

2 Pages

-

Catalog 35 - Static Eliminators

28 Pages

-

Catalog 35 - Safety Air Guns

15 Pages

-

Catalog 35 - Optimization

15 Pages

-

Catalog 35 - Air Wipes

12 Pages

-

Catalog 35 - Air Knives

18 Pages

-

Catalog 35 - Air Amplifiers

14 Pages

-

Catalog 35 - Accessories

13 Pages

-

Catalog 35 - Cabinet Coolers

22 Pages

-

Blowoff Guide

14 Pages