Catalog excerpts

Subject to errors or changes Editing completed January 2016

Open the catalog to page 3

Ex-tech Group is located at Forus in Stavanger, Norway, one of the world’s top Centers of Excellence within knowledge and technology related to the Oil and Gas industry. Our main office has all oil majors and NOC is located in close proximity. Our engineers, with experience from the oil and gas industry, are used to the strictest demands and specifications. The group consist of three fully owned subsidiaries, each with different competence and skills, enabling the group to be a complete and preferred supplier and partner in the Ex market. Ex-tech Solution

Open the catalog to page 4

Ex-tech Solution is our French subsidiary. The company (formerly Schneider Electric) has for more than 40 years been manufacturing a wide range of Ex components, equipment and solutions for the Oil & Gas onshore market. From small Ex switches and lamps to large Ex d enclosures for complex systems. A close and fruitful collaboration with French industry and local subsuppliers. Ex-tech Signalling is our second subsidiary in France. The company represents the groups center of excellence related to audio and visual signalling equipment, used mainly for signalling in combination with Fire & Gas...

Open the catalog to page 5

Control stations and signalling units The XAW control stations are equipped with our extensive range of our wide control and signalling units HarmAtex They combine the functions start and stop for motors, as fans, pumps, ... and they can be provided with measuring instruments for current control, voltage or other physical quantities. Motor starters, motor switches The 3 poles motor starters in protection modes Ex d IIB or Ex IIC meet all your needs for from 0.37 up to 37 kW. The wide range of enclosures combined with a wide range of contractors, thermal relays, allows real flexibility to...

Open the catalog to page 6

Ex regulations Atex and lECEx regulations IP rating IK rating Control stations Increased safety - Polyester, aluminium, stainless steel Flameproof - Aluminium - Gas group IIB and IIC Increased safety - Pendant stations Increased safety - Fire control station Control and signalling units HarmAtex Push buttons, emergency stops, selector switches, pilot lights, illuminated Foot switches Pull-wire switches Motor starters - Motor switches Flameproof Motor starters - Gas group IIB and IIC Increased safety Motor switches Junction boxes Increased safety - Polyester, aluminium, stainless...

Open the catalog to page 7

1. General information An explosive atmosphere is a result of the mixture with air, under atmospheric conditions and flammable substances in the form of gas, vapours, dusts, fibers which, once ignited, allow the combustion process to spread and permits selfsustaining propagation. Explosive atmosphere can be encountered, as result of technical processing sequences, in several industries such as: petrochemical, mills and silos generating combustible dust, in mining by the methane gas and coal dust. Further areas can develop explosive atmosphere like: paint industry, recycling industry,...

Open the catalog to page 8

Where do we find explosive atmospheres? • Metal surface grinding, especially aluminium dust and particles • Oil refineries, rigs and processing plants • Gas pipelines and distribution centres • Printing industries, paper and textiles • Aircraft refuelling and hangars • Chemical processing plants • Grain handling and storage • Sewage treatment plants • Surface coating industries • Underground coal mines • Woodworking areas • Sugar refineries • Power plants Where a potential explosive atmosphere can occur, certain safety levels need to be taken into account...

Open the catalog to page 9

4. Criteria of flammable substances Examples of the criteria for the mixture of flammable substances (gas) towards air in such a way that an explosion can occur are: Explosion range Explosion limit Lower 0% Concentration of flammable substances (1) LEL (Lower Explosive Limit) UEL (Upper Explosive Limit) Typical concentration of gas/vapours in the air where an explosion can appear (% vol. of gas in air): Ignition Energy Volume in percent gas/vapour in air 1. LEL (Lower Explosion Limit) 2. UEL (Upper Explosion Limit) 3. Optimum mixture 4. MIE (Minimum Ignition Energy) Ex-tech Solution

Open the catalog to page 10

- Product Directive 1994/9/EC - New product Directive 2014/34/EU - User Directive 1999/92/EC 5.1 Equipment Directive 1994/9/EC This directive has been mandatory in Europe from 01.07.2003, and covers the regulations concerning equipment and protective systems for use in potentially explosive atmospheres. This directive has four chapters which are subdivided into 16 articles. In each chapter it is made reference to the Annex I to XI, which include 7 modules. For full info visit http://ec.europa.eu/enterprise/atex/internationaldevelopment.htm Main part Annexes I II III IV V VI VII VIII IX X XI...

Open the catalog to page 11

5.2 Groups and categories The directive 1994/9/EC is dividing the equipment into groups and categories. - Equipment Group I apply for mining. This group is subdivided into categories M1 & M2 - Equipment Group II applies for all others (surface) areas. This group is subdivided into categories 1,2 and 3 NOTE: Equipment group III for dust according to EN/IEC 60079-0

Open the catalog to page 12

DO NOT OPEN WHEN ENERGIZED 2 Conformity mark with identification number of the Notified Body 3 Ex mark 4 Equipment group II 5 Equipment category 2 - Gas/Vapours and Dust 7 Product serial number 8 Certificate number according to ATEX standards 9 Certificate number according to IECEx standards 10 Ambient temperature range Marking for Gas/Vapours 11 Electrical apparatus to be installed in hazardous location 12 Type of protection: flameproof enclosure 13 Explosion gas group IIB 15 Equipment protection level Gb (high protection level) - Use in zone 1 and 2 Marking for Dust 16...

Open the catalog to page 13

5.4 Manufacturer’s Declaration of conformity Equipment and protective systems can be placed on the market, only if marked with the CE mark and complete with operating instructions and the manufacturer’s Declaration of Conformity. The CE conformity marking and the issued Declaration of Conformity confirm that the equipment complies with all requirements and assessment procedures specified in the EC Directives. Essential in the EC DOC is the harmonized standards ref; http://eurlex.europa.eu/ legalcontent/EN/TXT/PDF/?uri=uriserv:OJ.C_.2014.445.01.0005.01.ENG Note: According to Directive...

Open the catalog to page 14All Ex-Tech catalogs and technical brochures

-

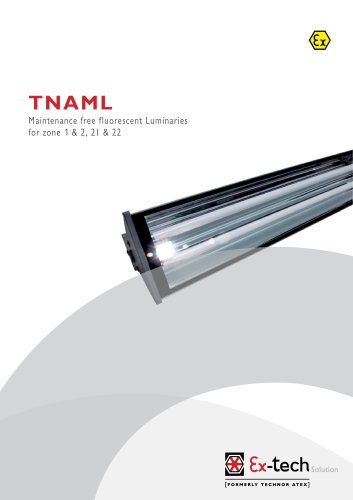

Fluorescent lighting

4 Pages

-

Enclosures

6 Pages

-

Safety switches

2 Pages

-

Junction boxes

2 Pages

-

Control stations

2 Pages

-

SB 125-1 Ex SOUNDER /BEACON

2 Pages

-

BC 150 Ex BEACON /LIGHT

2 Pages

-

BC 125 Ex BEACON /LIGHT

2 Pages

-

SD 125 Ex SOUNDER /HORN

2 Pages

-

SD 150 Ex SOUNDER /HORN

2 Pages

-

Ex-tech Solution

5 Pages

-

Flameproof enclosures

12 Pages

-

Limit switches

16 Pages

-

TNAML

20 Pages

-

SIGNALLING EQUIPMENT

24 Pages