Catalog excerpts

VISION AND INSPECTION UNIT evopro systems engineering AG | 2021

Open the catalog to page 1

VIU:VISION LEVEL Headless plattform Smart camera for inhouse projects Script solution to control hardware components Free programming of machining algorithms System includes simple pre-processing functions Release SW Prototype 0.1.0 March 2020 Scriptable machine vision Launch of VISIONWEB to configure and control evoVIU via web app from any device Launch of VISIONAPI to control evoVIU via HTTP rest commands Configurable endpoint communication for various protocol interfaces Costumized processing routines and workflows for business partners Launch of custom workflows to control and create...

Open the catalog to page 2

AUTOMOTIVE INDUSTRY AGRICULTURE & FOOD INDUSTRY LUMBER INDUSTY RESEARCH & SCIENCE Optical inline testing Deformation check Pattern recognition Research project Ripeness & Color change Branch detection Educational project Crack detection Pest detection Fungus detection Weld seam inspection Foreign body detection Insect detection evopro systems engineering AG | 2021

Open the catalog to page 3

VIU:HARDWARE Overview of all hardware components evopro systems engineering AG | 2021

Open the catalog to page 4

VIU:INTERFACE Various system interfaces Various protocols VIU:BASE Smart Camera - Basic Various camera sensors Different lense options VIU:LIGHT Various internal and external light modules Customized integration of various lighting systems and sensors VIU:MOUNTING Customized mounting systems for individual integration evopro systems engineering AG | 2021 Dimension: Protection class: Weight: Material:

Open the catalog to page 5

VIU:BASE Liquid-Lens Controlable up to 255 steps / High shock resistance 2.6 mm Pixelsize: 1,1 x 1,1 µm Image circle: 1/3“ Shutter: Rolling shutter Frame Rate: up to 30 fps Mono/Color: Color Exposure time: 68 µs to 2.3 s Pixelsize: 2,2 x 2,2 µm Image circle: 1/2.5“ Shutter: Rolling shutter Frame Rate: up to 60 fps Mono/Color: Color Exposure time: 43 µs to 1.4 s 16 GB eMMC system memory Up to 64GB on request NXP iMX8M – 1.5Ghz Quad Core with Vivante GC7000 GPU 4GB RAM evopro systems engineering AG

Open the catalog to page 6

VIU:INTERFACE Gbit-Ethernet M12-X-coded | Standard Power supply & Docker interface IO-Link M12-A-5pin 9 – 36VDC 1x Trigger input 2x Digital output IO-Link-driver M12-A-12pin 9 – 36VDC 2x Trigger input 4x Digital output 4x Analog IN/OUT Radio interface WiFi evopro systems engineering AG | 2021

Open the catalog to page 7

VIU:LIGHT Direct lighting Internal Diffuse lighting Internal Keyfacts: - Diffuse light module - Indivdiual settings and brightness for every LED - Up to 8 bright levels - TOF-depth-sensor Use cases: - Organic surfaces - Barcode - Labels - Field-View Diffuse lighting External Keyfacts: - Diffuse light module - Individual settings and brightness for every LED - Up to 4 bright levels Use cases: - Metal surfaces - Labels, Barcodes Direct lighting External Keyfacts: - Diffuse light module - Individual settings and brightness for every LED - Up to 8 bright levels Keyfacts: - Direct light module -...

Open the catalog to page 8

VIU:MOUNTING SIDE-DOCKER Compatible with the mounting system of the company Springer GmbH 38 mm Compatible with screw-on plates and individual mounting systems CUSTOM Do you have a special mounting system and you want to save installation space? Just contact us and we will help you with finding the best solution. evopro systems engineering AG | 2021

Open the catalog to page 9

evopro systems engineering AG | 2021

Open the catalog to page 10

VIU:VISIONWEB Control your VIU on any device evopro systems engineering AG | 2021

Open the catalog to page 11

NWEB Connect your VIU from anywhere LOOK HOW IT WORKS Runs on every web browser No installation or server required Up to 4 users on one evoVIU at the same time Editor and Viewer mode Access over Ethernet, Wifi or access point Works as access point, if no network is available evopro systems engineering AG | 2021

Open the catalog to page 12

Setup your image source Create, duplicate and delete Settings Capturing strategy Light settings Image format Trigger mode Exposure time Color space Color channel Balance ratio Contrast mode Zoom evopro systems engineering AG | 2021

Open the catalog to page 13

Setup your custom routine Create, duplicate and delete Camera orientation Acquisition strategy Intensity level Training sets Closing kernel Largest noise area Correction term Window size Smoothing kernel size Largest noise region Character numbers Code width Code height This is an example parameter set for the OCR recognition function. For other custom routines, these parameters may differ. The settings allow the user to adapt the function to different use cases and environmental situations. Image processing workflow Results evopro systems engineering AG | 2021

Open the catalog to page 14

Setup your connections Create, duplicate and delete Docker settings evopro systems engineering AG | 2021

Open the catalog to page 15

VIU:VISIONAPI Control light, lense, and system from anywhere LOOK HOW IT WORKS evopro systems engineering AG | 2021

Open the catalog to page 16

NAPI API-Connection to evoVIU LOCAL STORAGE Live view at display panel in office and at working space Save images and training sets Control evoVIU via TCP/IP – HTTP REST Image processing Teach and create training sets with AI React on environment and system changes with AI evopro systems engineering AG | 2021 CENTRAL STORAGE

Open the catalog to page 17

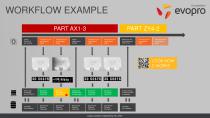

WORKFLOW EXAMPLE PART AX1-3 Create Part AX1-3 with settings Take picture from incoming part trigger Take picture from incoming part trigger Update image source settings PART ZY4-2 Take picture from incoming part trigger Take picture from incoming part trigger Delete part AX13 and create part PART ZY4-2 Take picture from incoming part trigger Take picture from incoming part trigger Start image processing via HTTP-REST Get picture Processing Decide OK Get picture Processing Decide NOK Change light settings based on training sets Get picture Processing Decide OK Get picture Processing Decide...

Open the catalog to page 18

SIMPLE COOPERATION INSTALLATION Exact positioning of evoVIU Use evoVIU setup assistant START WORKING Create, update and activate image source Take picture from incoming part trigger Take picture from incoming part trigger Take picture from incoming part trigger Start evoVIU at production begin Get picture Processing Decide OK Get picture Processing Decide OK Get picture Processing Decide OK Save picture Optimize training set Configure image source, save UUID Save picture Optimize training set Save picture Optimize training set Production worker Get UUID for used PART from worker Code...

Open the catalog to page 19All Evopro systems engineering AG catalogs and technical brochures

-

evoVIU_Produktflyer_VIU13

2 Pages

-

evoVIU_Produktflyer_VIU05

2 Pages