Website:

Evident - Olympus Scientific Solutions

Website:

Evident - Olympus Scientific Solutions

Group: EVIDENT

Catalog excerpts

Phased Array Inspections Probe Catalog Phased Array Probes and Wedges • Solution-Specific Probes • Angle Beam Probes • Immersion Probes • Integrated Wedge Probes • Curved Array Probes

Open the catalog to page 1

Table of Contents Technical Information Introduction to Phased Array Technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Custom Probes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Phased Array Probes Application Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Open the catalog to page 2

Introduction to Phased Array Technology High-Speed Scans with No Moving Parts The distinguishing feature of phased array ultrasonic testing is the computer-controlled excitation (amplitude and delay) of individual elements in a multielement probe. Through software, the excitation of multiple piezocomposite elements generates a focused ultrasonic beam, enabling the dynamic modification of beam parameters such as angle, focal distance, and focal spot size. To generate a beam in phase by means of constructive interference, the various active transducer elements are pulsed at slightly different...

Open the catalog to page 3

Custom Probes Phased Array Probes Olympus can manufacture custom phased array probes to suit specific applications and geometries. To develop your custom probe, we will need to know: • Application • Comparable UT single element transducer • Cable length • Number of elements, pitch, and elevation • Cable jacket required • Connector style • Array shape (flat, curved) • Probe type (angle beam, immersion, integrated wedge, matrix) • Housing restrictions and/or size constraints -- Curved in active dimension -- Curved in passive dimension (focused) Variable angle Dual linear Internal focus Phased...

Open the catalog to page 4

Connector type Cable length Cable type Casing type Probe type Frequency 1.5 = 1. 5 MHz 2.25 = 2 .25 MHz 3.5 = 3 .5 MHz 5 = 5 MHz 7.5 = 7 .5 MHz 10 = 10 MHz Additional frequencies available upon request Array type L = Linear A = Annular M = Matrix probe (1. 5D, 2D) CV (ROC) = Convex in azimuth CC (ROC) = Concave in azimuth CCEV (ROC) = Elevation focused ROC: radius of curvature (mm) Prefix Before Array Type D = Dual Array T = Tri Array Q = Quad Array Example DL = Dual Linear Array Casing type Casing type for a given probe type Cable type P = PVC Sheathing M = Metal Armor Sheathing HF =...

Open the catalog to page 5

Small-Diameter Pipe Welds (COBRA® Scanner) Weld Series Advantages • Design optimized for weld inspection • Leading-edge signal-to-noise ratio performance • Wide thickness range • Improved coupling to the part • Acoustically matched to Rexolite Typical Applications A31 and A32 Probes • Manual or automated inspection of 3 mm to 60 mm thick welds using angle beams • Innovative wedge design available for shear or longitudinal waves Advantages • Uses low-profile phased array probes with optimized elevation focusing for improved detection of small defects in thin-wall pipes Simulation displays a...

Open the catalog to page 6

Corrosion Mapping Austenitic, Nickel, and Other Coarse-Grained Alloys HydroFORM® Scanner Advantages • Local immersion technique • Coupling is optimized, enabling inspection of rough surfaces • Large coverage • Wedge reflection is eliminated • Easy synchronization on front wall for OD and ID corrosion monitoring Typical Applications I4 Probes Corrosion Mapping Applications • Manual or automated corrosion inspection of medium to large areas for remaining wall or internal corrosion measurements Dual Linear Array (DLA) Corrosion Probe Advantages • Pitch-catch technique • Considerable reduction...

Open the catalog to page 7

Wheel Probes RollerFORM® Scanner EdgeFORM™ Scanner Advantages • Exceptional coupling with minimal couplant • Easy set up for efficient C-scan • 25 mm (0.98 in.) water delay line enables inspection of composites up to 50 mm (1.97 in.) thick • Up to 51.2 mm (2.03 in.) wide beam coverage • Clear and low attenuation wheel material Typical Applications IWP1 Probes Composite Applications • Zero degree inspection of composite and other smooth-surface materials • Can be used in accordance with existing aircraft manufacturer procedures Probe Specifications and Dimensions Advantages • Exceptional...

Open the catalog to page 8

Laterally Focused Arrays (CCEV) These probes for girth weld inspection used with the PipeWIZARD system or COBRA® scanner have curved elements in the passive plane, focusing the beam in the lateral direction. An integrated lens permits the use of standard wedges. These cylindrically-focused probes significantly reduce oversizing and excessive repair. Their capacity to discriminate small indications is a major advantage when sizing the length of an intermittent defect using interaction rules. In addition, beam energy is better maintained in small pipe/thin wall applications. Advantages • PWZ1...

Open the catalog to page 9

Immersion Probes Immersion probes are designed to be used with a water wedge or in an immersion tank when the test part is partially or fully immersed. Advantages • Shortened dead zone at both ends (1.5 mm between center of first or last element and housing edge) • Well-suited for composite channel inspections • C-scan inspection of composites (delamination, disbonding, and porosity) Aqualene Wedge SNW1-0L-AQ25 The Olympus Aqualene wedge promotes exceptional coupling, improved measurements, and enhanced nearsurface resolution. Aqualene wedges are available for NW1, NW2, and NW3 phased array...

Open the catalog to page 10

Code Compliant ProbesDGS1 and A24 Atlas Series Probes 4L16-DGS1 Advantages • Acoustic impedance matched to water • High circumferential resolution around the radius • Corrosion-resistant stainless steel case • Waterproof up to 1 m (3.28 ft) underwater • Compatible with adjustable immersion wedges (shown on page 28) Typical Applications • Inspection of carbon fiber-reinforced polymer (CFRP) corners • Composite inspection for delamination Advantages • Probe and wedge in the same housing • Lowest-profile probe-and-wedge combination for contact angle beam inspection • Due to probe manufacturing...

Open the catalog to page 11All Evident - Olympus Scientific Solutions catalogs and technical brochures

-

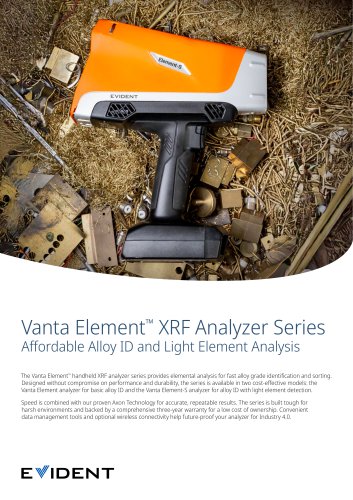

VANTA Element Brochure

8 Pages

-

VANTA Element Specifications

2 Pages

-

OmniScan X4

8 Pages

-

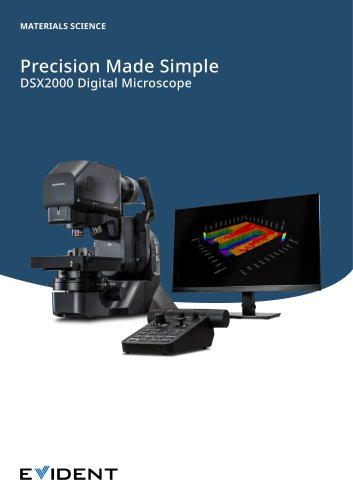

DSX2000 Digital Microscope

15 Pages

-

39DL PLUS

12 Pages

-

COBRA® Manual Weld Scanner

2 Pages

-

Rotating Billet Inspection

5 Pages

-

Spotweld Transducers

2 Pages

-

72DL PLUS™

8 Pages

-

Magna-Mike™ 8600

4 Pages

-

DC1–DC5

5 Pages

-

45MG

12 Pages

-

35 RDC

2 Pages

-

OmniScan MX ECA

2 Pages

-

NORTEC™ Scanners

2 Pages

-

OmniScan® X3 64

8 Pages

-

IPLEX GX/GT

8 Pages

-

IPLEX Long Scope

4 Pages

-

RVI General Overview

12 Pages

-

IPLEX TX

4 Pages

-

IPLEX G Lite

8 Pages

-

IPLEX GAir

8 Pages

-

IPLEX NX

12 Pages

-

Microscope Component Solutions

12 Pages

-

MXPLFLN Series

2 Pages

-

OLYMPUS Stream

16 Pages

-

LC35

4 Pages

-

DP74

8 Pages

-

DP28

8 Pages

-

SZX7

16 Pages

-

SZ61 SZ51 Brochure

24 Pages

-

SZX16 - SZX10

24 Pages

-

MX63/MX63L

20 Pages

-

GX53 Brochure

20 Pages

-

BXC Series Brochure

4 Pages

-

BX53M - BXFM Brochure

28 Pages

-

CIX100

16 Pages

-

STM7 Series

24 Pages

-

LEXT OLS5000

42 Pages

-

Vanta Overview

8 Pages

-

Vanta™ Handheld XRF Analyzer

8 Pages

-

Vanta™ iX Systems

4 Pages

-

Vanta™ iX Brochure

4 Pages

-

NORTEC 600

7 Pages

-

OmniScan X3 64 Brochure

8 Pages

-

OmniScan® X3 Brochure

8 Pages

-

Camera Overview

12 Pages

-

DSX1000 Brochure

40 Pages

-

72DL PLUS

8 Pages

-

Industrial Scanners brochure

36 Pages

-

IPLEX G LITE-W brochure

4 Pages

-

SZX-AR1

12 Pages

-

PRECiV 1.2 Brochure

20 Pages

-

Vanta GX Brochure

4 Pages

-

27MG

4 Pages

-

BondMaster 600

8 Pages

-

EdgeFORM™

2 Pages

-

EX Series Instruments

4 Pages

-

OpenView SDK

3 Pages

-

Mini_Wheel_Encoder

2 Pages

-

OmniScan MX

12 Pages