Catalog excerpts

Double wall steel storage tanks

Open the catalog to page 1

About us Fuel distribution solutions Since 2004, our company has shown continuous growth in the Romanian market. From simple traders we have become manufacturers. With an active presence in the Romanian business area and is addressing companies from different industries such as agriculture, construction, transportation, manufacturing, beverages, and the fuel industry. Eurial's business approach is focused on custom simple and automated solutions starting from designing to building and commissioning, using the highest technologies. Also, the company is trading several standard products...

Open the catalog to page 2

The passion for technology together with Eurial's technical capabilities and expertise places us among the top suppliers of tanks in Romania During the 18 years of activity, we have completed over 1000 complex projects, and the portfolio includes over 500 satisfied clients both from Romania and abroad. In the last years, we developed new markets in countries such as France, Hungary, Bulgaria, Republic of Moldova, where we accomplished various types of projects and established several partnerships. We rely on quality and professionalism and meet all the requirements imposed by international...

Open the catalog to page 3

Our team Eurial team is constantly involved and focused on a continuous development process both in terms of human capital and innovation as well. We are innovative, passionate, determined, hard-working professionals and we always put the client in the first place. Our technical resources, together with our management direction, have brought us credit from the largest local customers in a wide range of industries and opened new doors to the European market.

Open the catalog to page 4

What are Double-Walled Steel Storage Tanks? Overview and applications

Open the catalog to page 5

What above double-walled steel tanks are? ❑ Double-walled steel storage tanks are specially designed containers used for storing various substances, such as liquids and gases. ❑ They consist of two layers of steel, an inner tank and an outer tank, with an empty space (interstitial space) between them. Petroleum Industry: These tanks are widely used for storing petroleum products, such as gasoline, diesel, and jet fuel, in refineries, fuel stations, and industrial facilities. Chemical Industry: Double-walled steel tanks are suitable for storing various chemicals, including acids, solvents,...

Open the catalog to page 6

Technical features Characteristics and norms

Open the catalog to page 7

Technical Specifications Design norms: EN 12285-2 class A Material – S235JR according to EN10025-2 or steel Characteristics: Horizontal cylindrical shape with double steel wall 3 ” lockable filling quick cap according to DIN 28 450 standard Protecting coating with two components (200 microns) Abrasive grit-blasted to grade Sa 2,5 according to PN-ISO 8501-1 Overfill protection according to EN 13616 Suction tube integrated in the lid, with anti-siphoning valve Leak detector according to EN 13160 Level indicator with informative role, dipstick The tank is equipped with a DN 600 manhole Angle...

Open the catalog to page 8

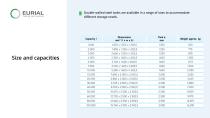

Double-walled steel tanks are available in a range of sizes to accommodate different storage needs.

Open the catalog to page 9

Technological production flow

Open the catalog to page 10

Design and planning The production process begins with the design and planning phase, where engineers and designers create detailed drawings and specifications for the double-walled storage tanks. Factors such as tank capacity, dimensions, material selection, and regulatory requirements are taken into consideration during this phase.

Open the catalog to page 11

Material Procurement ❑ Once the design is finalized, the production team procures the required materials. Common materials used for double-walled storage tanks include high-quality steel sheets, coatings, insulation materials, and accessories such as valves and fittings. ❑ It is essential to source materials from trusted suppliers to ensure the quality and integrity of the tanks. Cutting and Forming The steel sheets are cut according to the specified dimensions using specialized cutting machines. Computer Numerical Control (CNC) machines are often used for precision cutting. Eurial is using...

Open the catalog to page 12

The formed steel sheets are welded together using various welding techniques such as semi-automatic laser welding ESAB to create the tank's main structure. Welding and Fabrication Skilled welders meticulously join the steel sheets, ensuring strong and secure welds that maintain the tank's integrity. Additional components such as reinforcements, brackets, and flanges are also fabricated and welded onto the tank as per design specifications.

Open the catalog to page 13

Inner and Outer Tank Construction ❑ The double-walled feature of the storage tank requires the construction of both an inner tank and an outer tank. The inner tank is typically made of corrosion-resistant materials or coated with specialized liners to protect it from the stored substances. ❑ It is fabricated and welded separately. The outer tank provides an additional layer of protection and is constructed around the inner tank, leaving an interstitial space between them. Insulation and Coating To enhance the insulation properties and corrosion resistance of the tank, insulation materials...

Open the catalog to page 14

Blasting ❑ The blasting process involves cleaning and polishing a surface using a high-pressure jet combined with a blasting agent. The main role of sandblasting is to deeply clean any type of material, but sandblasting is also used to prepare the surface of an object for various final finishes. ❑ The blasting process is carried out in a blasting room, equipped with high-performance SAPI/MAMUT type equipment. ❑ The blasting room has large dimensions of L16x w 6 m x h5 m. ❑ Parts requiring blasting can weigh up to 20 tones and can have the following dimensions: 15 m x 5 m x 4 m. ❑ In the...

Open the catalog to page 15

Coating cabinet The cab is heated, there is the possibility to automatically adjust the temperature according to the paint manufacturer's requirements; AIRLESS Pump is used for high viscosity paints AIRMIX Pump is used for smooth, glossy surfaces). Paint types Two-component polyurethane paint: ❑ for 5-year warranty-two coats of 100 micron paint; ❑ for 10 years: 150 micron Professional industrial paints supplied by leading global manufacturers:

Open the catalog to page 16All Eurial catalogs and technical brochures

-

Eurial solution for CNG

24 Pages

-

Corporate Eurial

23 Pages

-

Optiteh - Fuel management system

29 Pages

-

Modern trends in agriculture

12 Pages

-

AdBlue Containerized Station

12 Pages

-

Mobile Gas Station

14 Pages

-

Metal box Storage Tank

12 Pages