Website:

Estic Corporation

Website:

Estic Corporation

Catalog excerpts

Z50 series AXIS Control Unit TRANSDUCERIZED FIXTURED NUTRUNNER ESTIC CORPORATION www.estic.co.jp Head Office & Osaka Sales Office 1-2-16, Togodori, Moriguchi-shi, Osaka, 570-0041, Japan Phone: +81-6-6993-8855 Fax: +81-6-6993-8875 E-mail: osaka_office@estic.co.jp Tokyo Sales Office 2F Shinyokohama Bousei Bldg., 3-20-12 Shin-Yokohama, Kouhoku-ku, Yokohama-shi, Kanagawa Pref. 222-0033, Japan Phone: +81-45-474-3036 Fax: +81-45-474-3037 E-mail: tokyo_office@estic.co.jp Chubu Sales Office Honda Bldg., 2-28, Kouseidori-minami, Okazaki-city, Aichi, 444-0044 Japan Phone: +81-564-66-0510 Fax: +81-564-66-0515 E-mail: chubu_office@estic.co.jp Hashiba Plant 2-5-9 Hashibahigashino-cho, Moriguchi City, Osaka, 570-0031 Japan Phone: +81-6-6993-8834 Fax: +81-6-6993-8881 Togo Plant 1-2-16, Togodori, Moriguchi-shi, Osaka, 570-0041, Japan Phone: +81-6-6993-8077 Fax: +81-6-6993-8887 SHANGHAI ESTIC CO., LTD. No. 6, 51 Gate, 1159 Lane, Kangqiao East Road, Pudong, Shanghai, 201315 China Phone: +86-21-6813-0333 Fax: +86-21-6813-0777 E-mail: ecc@estic.cn ESTIC (THAILAND) CO., LTD. 19 Naradhiwas Rajanakarin Road, Chong Nonsi, Yannawa, Bangkok, 10120, Thailand Phone: +66-2-678-0171 Fax: +66-2-678-0173 E-mail: sales@estic.co.th ESTIC AMERICA, INC. Head Office Novi Technical Center 1895 Airport Exchange Blvd., Suite 220, Erlanger, Kentucky, 41018 U.S.A. Phone: +1-859-746-8800 Fax: +1-859-746-8777 E-mail: support@estic-america.com 25901 Meadowbrook Rd. Novi, Michigan, 48375, U.S.A. Phone: +1-248-719-7622 ● The colors of the products may slightly differ from those of the actual products, which is inevitable in printing. ● The specifications and designs of the products may be changed without prior notice. This catalog uses vegetableoil ink. The contents of the catalog are as of November, 2023

Open the catalog to page 1

ELECTRIC FIXTURED NUTRUNNER Fixtured Nutrunner System High performance, high reliability Fixtured Nutrunner System ESTIC's nutrunner system realizes the highest level of accuracy, motor responsiveness, durability, and is suitable for various thread fastening operations which require traceability. ・Self-diagnosis function on each fastening ・Double structure torque monitoring Torque is not only monitored by the torque sensor, but also by current. Fastening operations are monitored, and crucial data, such as torque, angle and time is recorded. Management Software, and Touch Screens are...

Open the catalog to page 2

Fixtured Nutrunner System System Configuration Fixtured Nutrunner System Nutrunner systems can be configured in many combinations to fit a wide array of requirements. Allowing for flexible system building and I/O connection with PLC, allowing an external device to control the fastening sequence and data handling. MASTER CONTROL SYSTEM Nutrunner systems utilize digital communication protocols such as Ethernet and Fieldbus as well various user supported functions AXIS CONTROL SYSTEM A simple system in which the PLC and Controller are connected by I/O. such as HMI, and USB flash drives in...

Open the catalog to page 3

Tool Unit Tool Unit Durable, high speed, high accuracy tool unit in a small form factor. ENRZ-TU 001R-S Tool Unit Model TU:Standard tools TC:High speed Light-weight tools ▶Highly accurate torque detection is realized by 8 strain gauge type torque transducer with noise cancellation function. ▶A wide torque range from 0.5Nm up to 3000Nm is covered. ▶Suitable for various applications with Straight type, Offset type, Bent type, Angle head type. S:Straight type ST:Straight Bent type O:Offset type OP:Offset Bent type *A flange type is also available for the 3000N・m tool. Please check the website...

Open the catalog to page 4

Tool Unit Straight type Tool Unit Offset type * Tool model is different depending on the direction of the transducer. Refer to CAD data (https://www.estic-global.com/member/login) for the details. Anvil dimensions Offset type Straight type Bent type Straight type

Open the catalog to page 5

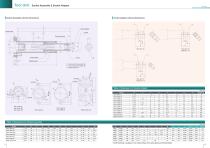

Tool Unit Socket Assembly & Socket Adapter Tool Unit Socket Assembly Socket Adapter Applicable tool unit Adapter insertion angle Socket assembly side - Socket side * Please consult with us when it is used for tightening above 36Nm. Reference drawing for mounting a socket assembly (the arrows A to A) TNA1-SA02-30 Mounting plate Tool unit and socket assembly are secured with bolts from the direction of view A-A. 1500Nm For Straight tool Notice ①When using with two or more spindles, please consider the moment due to a couple. We are also available to make custom socket assemblies for...

Open the catalog to page 6

Tool Unit Socket Assembly & Socket Adapter Tool Unit Socket Assembly external dimensions Socket Adapter external dimensions h Dowel (accessary) Needle bearing X : Initial load at home position (N) Y : Load at stroke end position (N) Z : Spring rate (N/mm) Mounting plate Table of dimensions for Socket Adapter Table of dimensions for Socket Assembly Unit : mm Dowel (accessary)

Open the catalog to page 7

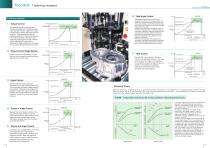

Tool Unit Tool Unit Fastening strategies Torque Control This fastening method is commonly used. Fastening is stopped when a predefined target torque has been reached. Judgment is made if the peak torque is within range of the upper and lower limit. If the fastening falls within the predefined range then an OK result is produced. If the fastening exceeds or falls short of the range then an NG judgment is made. With this system total judgment is performed by measuring the upper and lower limit of fastening time, as well as upper and lower limit for torque. Torque Control Angle Monitor...

Open the catalog to page 8

AXIS CONTROL UNIT AXIS Control Unit This control unit was developed for a single spindle. External Dimensions It accomplishes high accuracy, high quality fastening with simple configuration parameters. Monitor functions required for fastening come standard, and judgment is determined by torque, angle, time, or torque rate. Front Panel Wiring Data Display Indicator lamp ・Fastening OK: Green ・Alarm: Yellow ・Fastening NG: Red MOTOR Operation button ・Mode change ・Display change ・Parameter edit and set ・Real time torque value indication ・Final torque indication ・System error message indication...

Open the catalog to page 9All Estic Corporation catalogs and technical brochures

-

Servo Press MPU60

6 Pages

-

Large Tracer Arm

2 Pages

-

MAU55/AU55

2 Pages

-

Handy 2000 Cordless 2

2 Pages

-

EH2-T0070-P

2 Pages

-

Handy 2000 Series

2 Pages

-

ROBOT SYSTEM(ERS Series)

10 Pages