Website:

Estic Corporation

Website:

Estic Corporation

Catalog excerpts

Fastening Solutions ESTIC ROBOT SYSTEM

Open the catalog to page 1

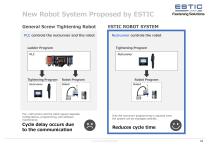

New Robot System Proposed by ESTIC General Screw Tightening Robot PLC controls the nutrunner and the robot Ladder Program Nutrunner controls the robot Tightening Program Tightening Program ESTIC ROBOT SYSTEM Robot Program Robot Program Robot PLC, nutrrunners and the robot require separate configurations, programming, and software maintenance. Only the nutrunner programming is required since the system can be managed centrally. Cycle delay occurs due to the communication Reduces cycle time

Open the catalog to page 2

ESTIC Fastening Solutions Process of the ESTIC ROBOT SYSTEM • Does the robot correspond to the reaction force of screw tightening ? • Is the speed sufficient ? • Is a magnetic or pneumatic screw feeder used ? • What about parts supply ? There are many things to be considered Robot Selection Nutrunner Selection Parts Feeder Selection Concept Design Ladder Programming Maintenance Management of PLC Software Robot Programming Maintenance Management of Robot Software System and Nutrunner Selection

Open the catalog to page 3

Features and Benefits Direct teaching Simple settings Tightening points can be taught by moving the robot directly. Vision position correction function (optional) Improves productivity With the correction function of the camera, even the slightest misalignments will not be missed. Hole misalignment correction function. Tightening Point Recording Button Master image Operating image Correct position of each tightening points.

Open the catalog to page 4

ESTIC Fastening Solutions Features and BenefitsZ-axiS Thrust Control Function Production Guarantee Prevents workpiece overload and cam out by tightening screws or bolts with the appropriate thrust. Dedicated Command^ Reduces Cycle Time Reduces communication time with the robot by using dedicated commands. Robot operations such as screw/bolt receivings and tightenings can be set in a batch on the nutrunner side. Step Function Detailed settings can be made by selecting an item from Tightening • Move • Return to the original position • Skip

Open the catalog to page 5

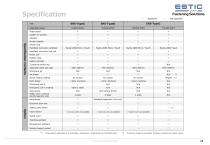

ESTIC Fastening Solutions Applicable robot Applicable handheld nutrunner Screw capacity *1 Torque range (N-m | ft-lb) Primary side power supply Primary air supply ERS-TypeC Conveyor compatible ERS-TypeA With workpiece pull-in device THE400-EM01 Handy 2000 Micro M1.7~M6 0.1~6.0 | 0.07~4.43 Single-phase 200V AC±10% (50/60Hz) 0.4MPa or higher ERS-TypeB Without workpiece pull-in device THE400-EM01 Handy 2000 Micro M1.7~M6 0.1~6.0 | 0.07~4.43 Single-phase 200V AC±10% (50/60Hz) 0.4MPa or higher *1 Excludes truss head screw

Open the catalog to page 6

Basic Configuration Working Range Component Unit Nutrunner Unit (Handy 2000 Micro/Touch) Robot Unit Power Unit Suction Unit Vacuum Equipment

Open the catalog to page 7

ESTIC Fastening Solutions Working Range Up and Down Stroke : 160mm Component Unit Power Unit Nutrunner Urnt: Robot Unit

Open the catalog to page 8

*1 Pneumatic adsorption is possible. (However, it depends on the bolt size) *2 Custom-made is possible. Please contact our sales team.

Open the catalog to page 9

ESTIC CORPORATION Moriguchi-city,Osaka, saJiSf! 570-0041 Japan JP : www.estic.co.jp EN : www.estic.co.jp/en/ CN : www.estic.co.jp/cn/

Open the catalog to page 10All Estic Corporation catalogs and technical brochures

-

Servo Press MPU60

6 Pages

-

Large Tracer Arm

2 Pages

-

Z50 Series

16 Pages

-

MAU55/AU55

2 Pages

-

Handy 2000 Cordless 2

2 Pages

-

EH2-T0070-P

2 Pages

-

Handy 2000 Series

2 Pages