Catalog excerpts

Clean Oven for FPD (HSC series) Features Supporting a substrate horizontally by pins which are placed on a substrate rack from below reduces “Thermal Image” failures. Countermeasures against Sublimates (Option) To reduce concentration of chemicals vaporized from glass substrates in the oven, a ventilating system takes in fresh air, this air is heated by a heater, and makes the air circulate. A sucking system installed on a shutter slit area sucks a leaking air to prevent diffusion. We installed Air-Blow system on under-side of shutter slit area to make more definitive exhaust. To keep your clean-room more cleanly, ceiling / under floor exhaust system can be installed in robot module. Specifications (Example) Processing glass size Operating range Temperature uniformity Max. 8th generation glass 100 300 4.5 at 230 on the glass surface

Open the catalog to page 1All ESPEC catalogs and technical brochures

-

TDDB Evaluation System

8 Pages

-

High-performance Clean Oven

12 Pages

-

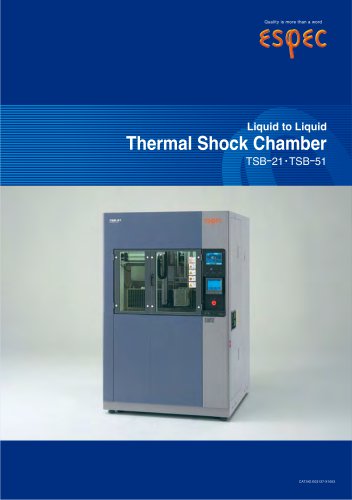

Thermal Shock Chamber (TSD-100)

16 Pages

-

Constant Climate Cabinet

8 Pages

-

Platinous J Series

40 Pages

-

Thermal Shock Chamber TSA series

24 Pages

-

Vacuum Ovens

16 Pages

Archived catalogs

-

High Performance Clean Oven

12 Pages