Catalog excerpts

Walk-in Test Chambers Panelized & Solid Construction

Open the catalog to page 1

Walk-in chambers are complex systems that can push the limits of lab space and utilities—ESPEC works to design a system that suits our clients’ test requirements. 2 ESPEC’s Custom Design Walk-ins Deliver the Chamber Performance & Size You Need From concept...

Open the catalog to page 2

4 Panelized Construction Panels are easy to move-in and assemble. Tongue and groove assembly is held together with cam-latches and silicone sealant. Embedded metal banding links the cam-latches together, creating a secure, strong unit when completed. Panelized chambers are built with interlocking insulated panels, making construction of any size with few troubles regarding move-in. See page 8 for an example of a extremely large drive-in chamber built with panels. • Standard sub-assemblies for quick delivery and lower cost. • Quality panels manufactured to ESPEC standards • Standard...

Open the catalog to page 4

5 The panels used in our chamber are 4" (100mm) thick urethane-foam sandwiched between a stainless-steel interior wall and a coated-steel exterior. An assembled box is self-supporting, so that no heavy structural members are required. Our conditioning MAP (see page 10) simply rolls-up to an assembled box to complete installation. Different door sizes, access ports, and other modifications are possible. For clients with steady-state or light-duty testing, ESPEC can offer coated-steel interior for cost savings, as well as the possibility of deleting the need for an insulated floor. The...

Open the catalog to page 5

6 Solid Construction Solid construction walk-ins can go up to 150°C, accommodating extreme test conditions that panelized chambers cannot. Solid chambers are also needed for temperature cycling faster than 10°C/m. • Full-opening doors • Extended temperature range to 150°C • Extended humidity range to 85/95% • Stronger standard floor, (600 lbs./sq. ft. static loading, carts up to 800 lbs.) • Rigid frame for strength • Stainless steel interior is hermetically weld An angle-iron outer frame supports the inner chamber and insulation space. The walls are reinforced with hat-channels....

Open the catalog to page 6

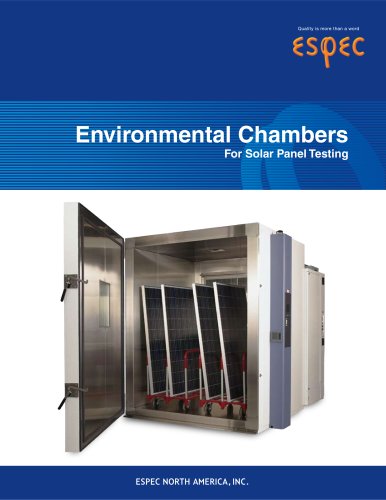

7 APPLICATION FOR SOLAR PANELS The IEC (International Electrotechnical Commission) established environmental testing methods for solar panels that include operation at 85°/85%, thus requiring solid construction chamber. The size and number of solar panels being tested at one time benefits from full-opening doors and heavy-duty floor construction. Because the MAP conditioner is separated for shipment, these units can be more easily shipped to countries where solar panels are being manufactured. The use of fiberglass insulation allows solid chambers to go to 150°C or more without any risk of...

Open the catalog to page 7

8 Drive-in Chambers Environmental testing of automobiles requires additional consideration of the facility where the chamber will be installed, and its planned use. Test methods for vehicles can include additional conditions besides temperature and humidity in an attempt to simulate real-world conditions. Drive-in chambers include: • Heavy-duty flooring to support vehicles • Large doors • Special MAP system with larger refrigeration and additional airflow capability. • Customization to suit additional test requirements. Four-post road vibration simulators can be combined with a drive-in...

Open the catalog to page 8

9 Chassis Dynamometer or Four-post road simulator — ESPEC builds special floor interfaces to allow use of these additional types of equipment supplied by other vendors. Infrared Lighting — ESPEC builds infrared systems to create radiant surface heating of vehicles to look for deformation and other quality problems. These systems can be adjusted vertically and angled to ensure even coverage. Running vehicle — From cold-start to highheat stress, a running engine is a common need, but complicated requirement. Fresh air must be conditioned and introduced to the chamber to make up for that used...

Open the catalog to page 9

10 Modular Air Plenums ESPEC standard air conditioning systems are called Modular Air Plenums (MAP). These MAPs are designed with the proper heating, refrigeration, and humidity control to achieve your desired performance and capabilities. The MAP simply rolls-up to a solid or panelized chamber to complete installation. Conditioning Plenum Includes: heaters, cooling coil, dehumidifying coil, and blower fans Humidity Generator Refrigeration System Reliable environmental control systems on ESPEC chambers are the result of standardized engineering, hand-built craftsmanship, and strict quality...

Open the catalog to page 10

11 ESPEC has four standard MAP sizes to suit different needs. Our application engineers will select the MAP type to fit the refrigeration and heating necessary. Humidity control systems are included when required. • MAP I --Two blower fans and larger C-frame refrigeration • MAP II --Two blower fans and compact refrigeration • Stability MAP --Two smaller fans and minimal refrigeration for steady-state applications • Drive-in MAP --Three blower wheels and larger C-frame refrigeration (not shown) • One-piece shaft, direct-drive blowers • High-volume humidity generators with easy maintenance •...

Open the catalog to page 11

STANDARD walk-in CHAMBERS Model Interior Volume Interior Dimensions * (WxDxH) Exterior Dimensions † (WxDxH) 9’ Deep Interior EPB364 10.3 cu. m (364 cu. ft.) 158 x 274 x 238 cm (62” x 108” x 94”) 2.9m x 3.0m x 2.7m (9' x 10' x 9') EPB499 14.1 cu. m (499 cu. ft.) 216 x 274 x 239 cm (85” x 108” x 94”) 3.5m x 3.0m x 2.7m (11' x 10' x 9') EPB634 17.9 cu. m (634 cu. ft.) 274 x 274 x 239 cm (108” x 108” x 94”) 4.1m x 3.0m x 2.7m (13' x 10' x 9') EPB770 21.8 cu. m (770 cu. ft.) 333 x 274 x 239 cm (131” x 108” x 94”) 4.6m x 3.0m x 2.7m (15' x 10' x 9') EPB904 25.6 cu. m (904 cu. ft.) 391 x 274 x 239...

Open the catalog to page 12

modular air plenums Temp/Humidity MAPL-6CWL MAPL-12CWL MAPL-15CW MAPL-30CW Temp Only MAPU-6CWL MAPU-12CWL MAPU-15CW MAPU-30CW Temperature Range -35°C to 85°C for Panel Construction (-31°F to 185°F) -35°C to 150°C for Solid Construction (-31°F to 302°F) Humidity Range 10 to 95% RH (MAPL models only) Example Change Rate * 0.25°C/m. 1.25°C/m. 2°C/m. 4°C/m. Single-stage Refrigeration 6 hp Scroll 12 hp Scroll 15 hp Semi-hermetic 30 hp Semi-hermetic Power 460V or 380V-415V Cooling Water with 30°C (85°F) Inlet 14 GPM (53 LPM) 23 GPM (87 LPM) 32 GPM (121 LPM) 53 GPM (200 LPM) Exterior Dimensions...

Open the catalog to page 13All ESPEC NORTH AMERICA catalogs and technical brochures

-

Company profile

24 Pages

-

Benchtop Test Chambers

8 Pages

-

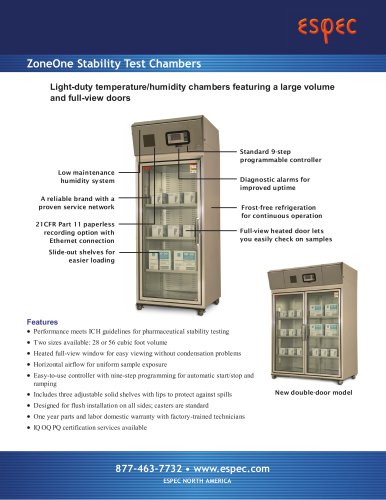

ZoneOne Stability Chambers

2 Pages

Archived catalogs

-

Industrial Ovens PDF Catalog

24 Pages

-

HAST Series PDF Catalog

12 Pages

-

TSA Thermal Shock PDF Catalog

20 Pages

-

TSD Thermal Shock PDF Catalog

16 Pages

-

TSE-11 Thermal Shock PDF Catalog

10 Pages

-

Global-N (460V) PDF Brochure

8 Pages

-

Platinous PDF Brochure

8 Pages

-

MC Series PDF Catalog

6 Pages

-

SU/SH & LHU Benchtop Catalog

16 Pages