Catalog excerpts

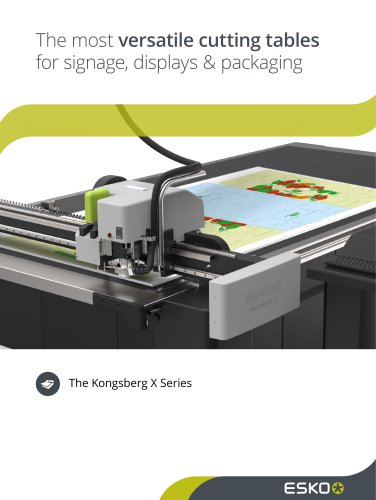

The most versatile cutting tables for signage, displays & packaging

Open the catalog to page 1

Complex production made easy on the industry’s most flexible platform In a world with rapid technology changes it is important to invest in equipment that offers the flexibility to cover your future needs. With the Kongsberg X, you can invest in the equipment you need today with the confidence than you can easily upgrade as your business grows. Add new materials, new applications, or more capacity so that you can add volume and enter new market segments.

Open the catalog to page 2

Layer Type To Crease Ore Shared Resources technology Simplifying is also replacing complex manual tasks with automation. The 'Shared Resources' functionality in the /-cut Production Console analyzes incoming files and automatically selects the right tool, the correct table settings and the cutting sequence. The result? Fast and consistent production, no matter who operates the table. You no longer need to wait for the most experienced operator to produce your more complex jobs. With Shared Resources, you can deliver the short turnaround time your customers demand.

Open the catalog to page 3

Whether you produce 2D signs, 3D displays, or packages; regardless of the material you work with, the Kongsberg X cutting table will meet the challenge. The application kits for the Kongsberg X (Designer, Sign Production, Packaging Production, and Flexo) make it easy to pick the right configuration for your business. Additionally, the freedom in upgrade options make the possibilities almost limitless. Packaging production This Kongsberg X model is optimized for packaging and flexo plate production. Mate -rial positioning brackets facilitate print-to-cut registration and enable cut, crease,...

Open the catalog to page 4

Steel construction tabletop The Kongsberg X series features the famous, rock-solid Kongsberg tabletop construction that will never warp or go out of level, even after decades of heavy use. Sheet automation Kongsberg Automate board feeder and stacker is an easy to use pallet to pallet material handling solution. The Kongsberg quality is paramount throughout production. Therefore we have specifically designed a board feeder that doesn’t damage the board or the print as it moves to the cutting table. Automated roll feeding is also available and it’s even integrated with sheet feeding to meet...

Open the catalog to page 5

Kongsberg X Toolheads: Powerful and versatile MultiCUT-HP The MultiCUT-HP (High Power) is equipped with a super-strong, liquid-cooled milling spindle delivering several times higher productivity than less powerful alternatives. The combination of high power and efficient cooling makes this a great choice for shops that need extended milling duty cycles and/or who work extensively with heavy-duty materials (thick sheets of acrylic, wood/MDF and aluminum composite material). The FlexiHead offers highly accurate, powerful cutting — on all flexible and thin materials such as paper, folding...

Open the catalog to page 6

Bits & Blades that Make a Difference Quick and error free Tool Exchange Exchanging tools on a Kongsberg X is fast, simple and error proof. Just insert a tool and hit Start. Every tool is identified by a unique bar code with tool parameters stored in memory, preventing any operator errors. Psaligraphy knife tool for the finest details The Psaligraphy knife tool easily cuts any intricate detail in paper and folding carton, at a unprecedented quality level. Make products like greeting cards, invitation cards, promotional items and folding carton samples with high precision, burr-free cuts....

Open the catalog to page 7

Kongsberg X Starter bundles Upgradable to fit your future business needs Kongsberg X starter bundles are tailored to make samples or perform short production runs. The X Starter bundles share platform, tooling equipment and production console (iPC) with the standard Kongsberg X . The Starter bundles are upgradable; more speed can be added at a later stage (Speed Upgrade) when your business needs more shor t run capacit y or if your business expands the range of materials that needs to becut. Kongsberg X Starter is a safe investment with Kongsberg’s long lifetime and high second hand value....

Open the catalog to page 8

BUNDLE DESCRIPTION

Open the catalog to page 9

Producing CORRUGATED BOX_waste divider.cut Producing copy Since start: Material thickness: User Experience personalized The /-cut Production Console, the front-end for the Kongsberg X, works with a graphical icon based communication which allows the operator to supervise production from a distance. A separate operator login ensures personalized language settings and job list management. My Job List Full editing rights from estimating and production plan -ning to job/batch countdown increase efficiency and ensure on time delivery. History jobs can be recalled and reproduced.

Open the catalog to page 10

Device Manager The Device Manager offers machine visibility from everywhere. It shows all ongoing jobs and lets operators distribute those to optimize the use of the Kongsberg table(s). Device Manager helps reduce lead times and eliminates material waste; it enables managing short production runs intelligently and optimizes equipment performance. Device Manager is an option for i-PC.

Open the catalog to page 11

Keeping control in short run production Streamline your operations ‘From order in to invoice out’. Find out the top 6 areas to reduce waste and add value! 1. 3D Display Design •• POP design made easy with the ArtiosCAD Display Store •• Reduce POP display design time by 90% •• E x p a n d y o u r p o r t f o l i o , o f f e r profitable 3D applications 6. Shipping •• Produce per fec t shipping boxes on demand with QuickBox •• Eas y inter face: jus t enter the box dimensions •• Cut the box directly on the Kongsberg cutting table Visit www.esko.com/solutions/digital-finishing to find out how...

Open the catalog to page 12

2. Approval •• Speed up customer approval cycles •• Use 3D files to communicate with customers •• Switch to vir tual mock-ups and save up to 90% 3. Prepress •• M a k e f i l e s p r i n t- r e a d y w i t h dedicated sign software •• Optimal nesting, adding bleed, tiling… •• Get it right the first time, no tryand-error, avoid expensive rejects 4. Estimation •• Get a status view of your digital finishing tables from anywhere •• Automatic estimation of your jobs

Open the catalog to page 13All Esko-Graphics catalogs and technical brochures

-

ArtiosCAD module descriptions

12 Pages

-

Automation Engine

8 Pages

-

CDI Family

6 Pages

-

CDI Crystal overview

6 Pages

-

HD Letterpress

3 Pages

-

ArtPro+

4 Pages

-

CDI Spark Family

6 Pages

-

WebCenter

8 Pages

-

SUITE 14

12 Pages

-

I-CUT SUITE

8 Pages

-

HD FLEXO - FULL HD FLEXO

4 Pages

-

equinox

2 Pages

-

Digital Flexo CDI

16 Pages

-

ColorEngine

2 Pages

-

_Kongsberg_iXE10_us

8 Pages

-

_ArtiosCAD_us

4 Pages

-

Kongsberg flatbed plotting table

6 Pages

Archived catalogs

-

Studio

10 Pages

-

_DotSpy_us

2 Pages

-

_GraphicEditor_us

12 Pages