Catalog excerpts

HD Flexo - Full HD Flexo The new quality standards for flexo printing HD Flexo and Full HD Flexo are flexo solutions that make sure you do not have to compromise on print quality. You can have the strong solids with vibrant brand colors and the sharp text and image details and the smooth vignettes. Flexo no longer comes second to gravure or offset. Plates and sleeves made with HD Flexo and Full HD Flexo deliver consistent and repeatable results that will make you smile. HD Flexo has set the new flexo printing standard for fine highlights, transition to zero, sharp text and brilliant image details. Full HD Flexo is adding perfect ink laydown with the right solid density, vibrant brand colors, supreme platemaking consistency and the only fully digitally controlled platemaking workflow available in industry. Now flexo can compete with gravure and offset in flexible packaging, labels and corrugated printing applications.

Open the catalog to page 1

HD Flexo: today’s flexo quality standard HD Flexo has quickly become the new standard in flexo printing. HD Flexo is a process for making digital flexographic plates and sleeves for high quality flexo printing. Plates and sleeves give more consistent and higher quality results on the press. HD Flexo can be implemented by upgrading existing Esko CDIs and software. HD Flexo offers improved colors, smooth vignettes and sharp details. HD Flexo matches offset and gravure quality and consistency levels. It has raised the industry standard for flexo printing. HD Flexo is able to create a textured...

Open the catalog to page 2

Full HD Flexo: no compromises Full HD Flexo combines all the benefits of HD Flexo with a gravure-like ink laydown and a fully digitally controlled platemaking workflow. Full HD Flexo brings a level of quality and consistency with no need for compromises. How does it work? The Full HD Flexo technology combines high resolution imaging at 4000ppi (HD Flexo imaging and screening technology) with digitally controlled main exposure inside the CDI. The digital Inline UV2 main exposure through a LED-array delivers a UV power density high enough to gain full control over the polymerization process...

Open the catalog to page 3

Full HD Flexo benefits. HD Flexo configurations can be upgraded to Full HD Flexo, if the CDI is upgraded to Inline UV2 and the necessary software updates are implemented. For each application a Standard Operating Procedure guarantees the best results. Full HD Flexo for labels • Considerable reduction of mottling on lower cost substrates • Improvement in ink density • Reduction of gear marks • Greater stability in the highlights Full HD Flexo for corrugated post-print • Fluting reduction • Improved image quality • Improved highlight stability • Better ink laydown, even with harder printing...

Open the catalog to page 4All Esko-Graphics catalogs and technical brochures

-

ArtiosCAD module descriptions

12 Pages

-

Automation Engine

8 Pages

-

CDI Family

6 Pages

-

CDI Crystal overview

6 Pages

-

HD Letterpress

3 Pages

-

ArtPro+

4 Pages

-

CDI Spark Family

6 Pages

-

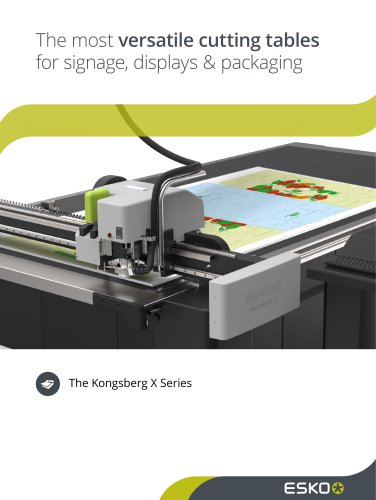

The Kongsberg X Series

16 Pages

-

WebCenter

8 Pages

-

SUITE 14

12 Pages

-

I-CUT SUITE

8 Pages

-

equinox

2 Pages

-

Digital Flexo CDI

16 Pages

-

ColorEngine

2 Pages

-

_Kongsberg_iXE10_us

8 Pages

-

_ArtiosCAD_us

4 Pages

-

Kongsberg flatbed plotting table

6 Pages

Archived catalogs

-

Studio

10 Pages

-

_DotSpy_us

2 Pages

-

_GraphicEditor_us

12 Pages