Catalog excerpts

Innovating digital flexo

Open the catalog to page 1

A history of flexo innovation For decades Esko has been developing software and hardware solutions for the packaging industry. The company invented digital flexo in 1995 and has been leading the development ever since - their products are used in about 90% of high quality flexo production. Today, Esko is synonymous with excellent quality and consistency in all flexo printing applications.

Open the catalog to page 2

Innovating digital flexo Over 90% of all digital flexo plates globally are imaged on a Cyrel Digital Imager (CDI) made by Esko. These CDIs enable superb results that before were only achievable in offset or gravure. With the CDI, trade shops are able to of fer superior quality, while printers receive print consistency. It’s no surprise that the CDI is the most popular digital flexo plate imager in the world. Constant improvements Flexo technology continues to advance. As the absolute leader in flexo innovations, we continue to rethink all steps of the flexo process: can we make it better?...

Open the catalog to page 3

An imager that matches your needs You can choose and configure a CDI to match your current production needs, and expand capabilities as your business grows. The CDI can accommodate all plate and sleeve sizes. And, you have the freedom to choose any brand of digital plate and processing method. Match your CDI to your production needs. From left to right: CDI Spark 2530, CDI Spark 4835 and the CDI Spark 4260. Flexible resolutions and speed All CDIs are equipped with Fiber lasers and dedicated optics that guarantee superior and reliable imaging. All CDIs feature fully variable imaging...

Open the catalog to page 4

Widest choice of flexo plates and sleeves With a CDI, you can image flexo plates and sleeves for virtually any kind of application. With the CDI family’s broad selection of sizes, you can choose from the widest variety of plate sizes. Any type and brand of digital flexo, digital letterpress plate or ablative film can be used on a CDI. Digital polyester base Letterpress Flat Silk Screen Digital Silk Screen Digital Film Conventional flexo plates Digital Flexo Plate handling The off-line plate-loading table provides safe, damage-free and distor tion free plates throughout the entire plate...

Open the catalog to page 5

Stay ahead HD Flexo and Full HD Flexo: the new standards for flexo quality The quality of offset and gravure printing used to be unattainable for flexo. Now, with HD Flexo and Full HD Flexo, the gap is closed. Bringing consistency and repeatability, smooth transitions, perfect ink laydown and vibrant colors with increased print quality, HD Flexo and Full HD Flexo raise the industry standard in flexo printing. For more info, see page 12. Automate your flexo production The Digital Flexo Suite offers significant cost and time savings through the automation of the flexo print plate production....

Open the catalog to page 6

Flexo benefits Faster ready to print By making almost every step in the flexo workflow automatic, and by increasing the overall quality, flexo becomes a very attractive print process. It cannot be beaten in terms of cost efficiency and speed. Reduce the amount of repro work with HD Flexo. Speed up your plate production with the automation tools of the Digital Flexo Suite. Repeatable quality The superior plate quality from a CDI with HD Flexo is exactly what a printer needs to achieve outstanding results: fine highlights, excellent details and superb coverage in the shadows. The CDI delivers...

Open the catalog to page 7

Sleeves: a seamless flexo process Using sleeves increases the printing press speed and delivers perfect register. There are no deformed or distorted sleeves after processing, resulting in the best geometric accuracy. Digital flexo sleeves can compete with gravure to print snack food wrappers, pouches, and frozen food bags that typically carry continuous images and only require a single cut prior to packing and sealing. Seamless sleeves with CDI Advance Cantilever CDI seamless sleeves can be imaged on the CDI Advance Cantilever 1750 and the CDI Advance Cantilever 1450. For midweb sleeve...

Open the catalog to page 8

Inline UV for maximum precision A major leap forward in flexo technology is digtal plates with UV main exposure. Digital plates get UV main exposure in the same device in which they are imaged. This means that no subsequent exposure is required on an offline light frame. Combining these two processes in one device brings cost down, reduces errors and boosts quality. The Inline UV Main Exposure option increases the quality and reliability of digital flexo plates by ensuring that each square centimeter of the plate receives the same amount of UV light needed to fully polymerize the plate. It...

Open the catalog to page 9

Automate your flexo plate production Digital Flexo Suite Data Transfer Digital Flexo Suite Kongsberg Table Mounting Machine The Digital Flexo Suite offers significant cost savings through the automation of flexo plate production. It is a collection of Esko’s plate making software, designed especially for the needs of the flexo plate production and mounting. There is a Digital Flexo Suite for labels, flexible packaging and corrugated workflows. Digital Flexo Suite enables operators to prepare multiple jobs and simultaneously drive several CDI’s. Each imaged and cut plate receives a detailed...

Open the catalog to page 10

Benefits • Customers report an average plate waste reduction of 15% from the Digital Flexo Suite. • Automation of complex manual labor leads to less human mistakes. • Each imaged and cut plate automatically receives a detailed plate report. This report can be used for quality control and invoicing. • Automated carrier sheet preparation. • Reducing plate waste has a direct positive impact on the CO2 balance. Kongsberg digital cutting tables cut the flexo plates quickly and accurately. The cut patches are reassembled on carrier sheets.

Open the catalog to page 11

HD Flexo and Full HD Flexo: the new standards for flexo quality HD Flexo has set the new flexo printing standard for fine highlights, transition to zero, sharp text and brilliant image details. Full HD Flexo is adding perfect ink laydown with the right solid density, vibrant brand colors, supreme platemaking consistency and the only fully digitally controlled platemaking workflow available in industry. Now flexo can compete with gravure and offset in flexible packaging, labels and corrugated printing applications. HD Flexo and Full HD Flexo benefits • moother, sharper images with expanded...

Open the catalog to page 12All Esko-Graphics catalogs and technical brochures

-

ArtiosCAD module descriptions

12 Pages

-

Automation Engine

8 Pages

-

CDI Family

6 Pages

-

CDI Crystal overview

6 Pages

-

HD Letterpress

3 Pages

-

ArtPro+

4 Pages

-

CDI Spark Family

6 Pages

-

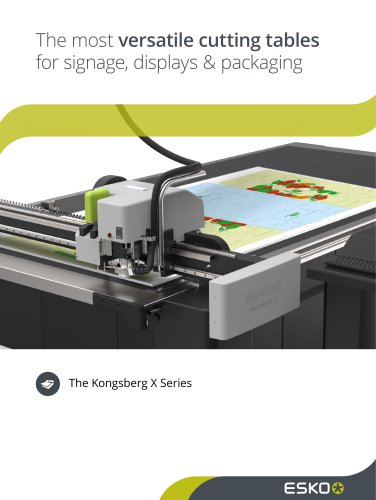

The Kongsberg X Series

16 Pages

-

WebCenter

8 Pages

-

SUITE 14

12 Pages

-

I-CUT SUITE

8 Pages

-

HD FLEXO - FULL HD FLEXO

4 Pages

-

equinox

2 Pages

-

ColorEngine

2 Pages

-

_Kongsberg_iXE10_us

8 Pages

-

_ArtiosCAD_us

4 Pages

-

Kongsberg flatbed plotting table

6 Pages

Archived catalogs

-

Studio

10 Pages

-

_DotSpy_us

2 Pages

-

_GraphicEditor_us

12 Pages