Catalog excerpts

Next generation flexo plate making Simple, consistent & automated Crystal Technology

Open the catalog to page 1

XPS Crystal: Improving consistency with patented UV LED exposure Plate consistency is one of the keys to achieve, and maintain optimal print quality. One of the main factors influencing plate stability is the plate's UV exposure. The innovative XPS Crystal optimally combines UV main and back exposure. Unlike UV frames using light bulbs fluctuating in output the XPS Crystal uses UV LEDs which don't need warmup time and always emit consistent radiation. A synchronised and optimally controlled UV main and back exposure produces highly consistent digital flexo plates - for every digital flexo...

Open the catalog to page 2

Rethinking the flexo plate making process CDI Crystal: simplified flexo imaging The Esko CDI Crystal 5080 lays the groundwork for full integration and automation of plate imaging and UV exposure. In today’s market, rushing jobs at the last minute at high quality has become the norm. Traditional multi-step flexo plate making pro- •• Basis for reducing plate room complexity cesses are hindering produc tivit y. They are •• Based on proven Esko CDI laser imaging technology and high resolution optics causing errors and rework; and reduce press uptime. In the end, that harms the productivity and...

Open the catalog to page 3

Removing complexity through automation The integration and automation of digital imaging and LED UV exposure improves consistency and overall ease of use. This solution not only With the CDI Crystal 5080 XPS, Esko redefines frees up valuable operator time but also reduces flexo plate making from scratch. maintenance and the footprint of your f lexo equipment. Usually, this process consists of many complex and manual steps, which not only takes time, it also offers ample opportunity for human errors. •• Reduce manual steps by 50% The CDI Crystal 5080 XPS is the answer: instead •• Reduce...

Open the catalog to page 4

Combined main and back exposure with UV LED lights. Same floor relief over the entire plate, always Stable and repeatable print quality on press Intuitive user inter face, less errors, less operator training Glass plate table for easy automatic unloading Accepts plates from several CDIs as a modular unit Both CDI Crystal and XPS Crystal are each available as stand-alone device. Improved ergonomics and serviceability for ease of operation

Open the catalog to page 5

Flexo plates need to be ready fast, within a reli- The operational control over the CDI moves able deliver y time. Converters cannot af ford upstream in the production workflow. presses to be down just because they’re waiting for new plates. With Device Manager, the prepress department has all the necessary information to prioritize Esko’s Automation Engine comes with an auto- and organize plate making queues to produce mated flexo platemaking module. There’s no the right plate at the right time. The work in longer need for manual interventions, the files progress, status and the queues of...

Open the catalog to page 6All Esko-Graphics catalogs and technical brochures

-

ArtiosCAD module descriptions

12 Pages

-

Automation Engine

8 Pages

-

CDI Family

6 Pages

-

HD Letterpress

3 Pages

-

ArtPro+

4 Pages

-

CDI Spark Family

6 Pages

-

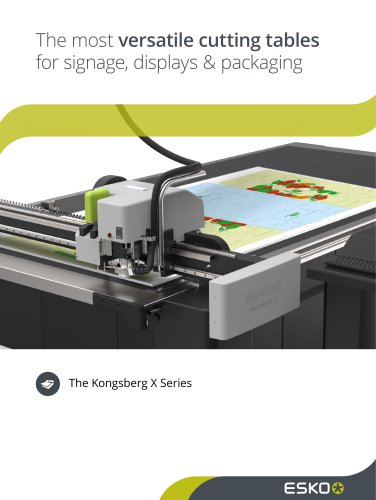

The Kongsberg X Series

16 Pages

-

WebCenter

8 Pages

-

SUITE 14

12 Pages

-

I-CUT SUITE

8 Pages

-

HD FLEXO - FULL HD FLEXO

4 Pages

-

equinox

2 Pages

-

Digital Flexo CDI

16 Pages

-

ColorEngine

2 Pages

-

_Kongsberg_iXE10_us

8 Pages

-

_ArtiosCAD_us

4 Pages

-

Kongsberg flatbed plotting table

6 Pages

Archived catalogs

-

Studio

10 Pages

-

_DotSpy_us

2 Pages

-

_GraphicEditor_us

12 Pages