Website:

Eredi Caimi S.r.l.

Website:

Eredi Caimi S.r.l.

Catalog excerpts

__NormTec Molded fiber products for product protection and transport NormTec molded fiber products are produced from up to 100 % recovered paper and are characterised by high rigidity and stability even under strong stress. This manufacturing process focuses on the cushion and protection functions. The geometry of the molded fiber product adapts optimally to the product contour and thus guarantees reliable cushioning. The most important benefits of the NormTec quality •- _ outstanding product and transport protection _ suitable for high product weights _ for part dimensions up to 2,000 x 800 x 200 mm _ grey/brown _ 100 % recyclable can be nested in each other _PressTec Molded fiber products for transport protection and presentation During this manufacturing process, a NormTec molded fiber product is smoothed by an additional process step - the hot pressing - and brought into the final form. This significantly reduces the amount of space required for transport and storage. The smooth surface and flatness of the products ensure their interference-free automated processing. A PressTec molded fiber product is characterised by optimised handling in the packaging process and a precise fit. The most important benefits of the PressTec quality •- _ smoother surface _ exact fit _ 100 % recyclable _ exceptionally easy to integrate in handling systems _ optimised pack density _FineTec Molded fiber products for the highest requirements The FineTec quality is produced from up to 100 % recovered paper. The special feature of this process is the increased strength of the molded fiber products as compared with the PressTec process; as a result, up to 30 % of the normal material usage can be saved. The smooth surfaces make FineTec molded fiber products particularly suitable for use in the fixing of products and for holding precision components in place. The most important benefits of the FineTec quality •- _ perfect presentation and holding in place _ high dimensional accuracy and precision _ automated processing _ in-line highly compressed surfaces and high strength _ 100 % recyclable _ optimised pack density drying and pressing station AUTO CERTIFIED QUALITY Eredi Caimi S.r.l. - via G. Pascoli 139/141 21057 Olgiate Olona (VA) MAIL: info<a>eredicaimi.it final inspection

Open the catalog to page 1All Eredi Caimi S.r.l. catalogs and technical brochures

-

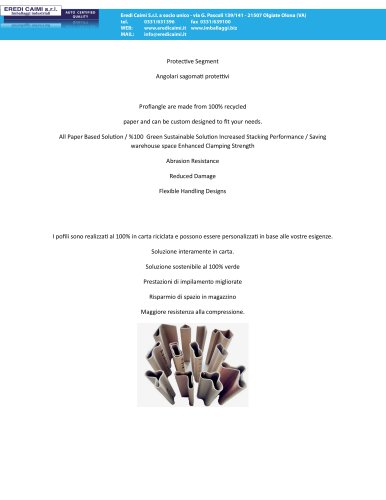

protective segment

4 Pages

-

general pulp flex

2 Pages

-

box eco pulp

2 Pages

-

air cargo system pallet

5 Pages

-

wrap pulp

7 Pages

-

new componible crate

7 Pages

-

paper system protection

1 Pages

-

cushon paper samples

4 Pages

-

About our pulp production

8 Pages

-

New pulp solution 2019/2020

2 Pages

-

Pulp top finish surface

2 Pages

-

Pulp biodegrdable packaging

5 Pages

-

case study pulp molded

1 Pages

-

honeycomb packaging

6 Pages

-

plastic collar

1 Pages

-

dunnage bags 2019

9 Pages

-

worldpack

2 Pages

-

corner structure

2 Pages

-

corner roll edge

1 Pages

-

corner pre cut

1 Pages

-

corner huge board

1 Pages

-

corner combination packaging

1 Pages

-

corner coating

2 Pages

-

corner production

9 Pages

-

corner adhesive

1 Pages

-

New molded pulp production

1 Pages

-

medical pulp packaging

1 Pages

-

chemic pulp packaging

1 Pages

-

wine pack magnum

1 Pages

-

wine pack 3/1

1 Pages

-

wine pack 1/3

1 Pages

-

wine pack 1/2

1 Pages

-

box 800x600

1 Pages

-

box 1200x800

1 Pages

-

edge runner for box

2 Pages

-

case study carton box

7 Pages

-

void filler

2 Pages

-

airbag packaging

5 Pages

-

cuschion paper

3 Pages

-

edge protector corner

6 Pages

-

pallet machine assembled

3 Pages

-

pulp molded packaging

8 Pages

-

wood collars

3 Pages

-

molded paper projects

10 Pages

-

thermal cover for pallets

1 Pages

-

cardboard square tube

2 Pages

-

thernal solution

2 Pages

-

WHOLE PULP PACKAGING

1 Pages

-

PALLET PULP PACKAGING

1 Pages

-

CRADLES PULP PACKAGING

1 Pages

-

CHEMICAL PULP PACKAGING

1 Pages

-

FrameCut Profiles

4 Pages

-

Insulated bags

4 Pages

-

Mod-Box

2 Pages

-

Bend Pulp

2 Pages

-

Durable Pallets and Boxes

10 Pages

-

thermal cover

3 Pages

-

PLATEAUX AUTOMOTIVE

5 Pages

-

new patent protection

1 Pages

-

plastic box

9 Pages

-

container galvanized

7 Pages

-

equipment for handling

31 Pages

-

heating blankets for ibc

3 Pages

-

heating blankets

3 Pages

-

PLASTIC CASES

62 Pages

-

LOGISTIC COMPONENT

6 Pages

-

adhesive carton corner

2 Pages

-

flanges and spools plastic reels

10 Pages

-

roll cradles pulp

3 Pages

-

u corner profile

2 Pages

-

slipsheet

4 Pages

-

round profile

2 Pages

-

pallrun

4 Pages

-

honeycomb

2 Pages

-

frame box corner

2 Pages

-

flatboard

2 Pages

-

edge board

4 Pages

-

edge runner

2 Pages

-

carton pallet

4 Pages

-

plastic profil edge

3 Pages

-

bio system

2 Pages

-

LIQUID BOX

1 Pages

-

PULP PALLET

1 Pages

-

moulded paper pulp

11 Pages

-

cardboard display

6 Pages

-

carboard display

6 Pages

-

THERMAL BOX

9 Pages

-

extension pallet

2 Pages

-

paramedical packaging

1 Pages

-

industrial packaging

2 Pages

-

higiene packaging

1 Pages

-

food packaging

1 Pages

-

detergent packaging

1 Pages

-

conserving packaging

2 Pages

-

chemical packaging

1 Pages

-

catering packaging

1 Pages

-

beverage packaging

2 Pages

-

agricultural packaging

2 Pages

-

flexible carton protection

4 Pages

-

vario system packaging

4 Pages

-

BOX ELETTRONICS COMPONENT

29 Pages

-

CHEMICAL BOX

3 Pages

-

BOX FOLDABLE

3 Pages

-

BOX AUTOMOTIVE COMPONENT

29 Pages

-

BOX AUTOMOTIVE EXTERIOR

21 Pages

-

BOX AUTOMOTIVE INTERIOR

29 Pages

-

PLASTIC OCTABIN

7 Pages

-

galvanized pallets

11 Pages

-

extension pallet

2 Pages

-

CARTON PALLET FOR BAG

4 Pages

-

DISPLAY PROFILE

2 Pages

-

FRAME

2 Pages

-

carton pannel honeycomb

3 Pages

-

SAMPLE WINE BOX

17 Pages

-

SAMPLE POLISTIRENE

31 Pages

-

SAMPLE WOOD

9 Pages

-

box pally

4 Pages

-

pally sistem

2 Pages

-

EURO CASSETTE

2 Pages

-

paper pall

3 Pages

-

saddle-cradles universal

2 Pages

-

new model plastic box

19 Pages

-

international presentation

17 Pages

-

box s

2 Pages

-

box ppl cuttering

24 Pages

-

tray pallets container

1 Pages

-

magnum box pallet

2 Pages

-

load security pallets

1 Pages

-

frame pallets

1 Pages

-

hygienic pharmacy pallets

1 Pages

-

folding box

2 Pages

-

euro pallets

1 Pages

-

collecting trays

7 Pages

-

big boxex

2 Pages

-

offset production

5 Pages

-

flex profile

2 Pages

-

frame box

2 Pages

-

load edge

2 Pages

-

profil general

24 Pages

-

dunnage bags

2 Pages