Catalog excerpts

ERDWICH SINGLE-SHAFT-SHREDDER Advantages and special features ERDWICH M800/1 Cutting rotor: | Single placed knife discs enable an individual assembly on the cutting rotor. So the flow of materials in the cutting unit is perfectly adapted to customer´s requirements. Knife geometry: | via special pressure angle of knives perfect pulling-in and best shredding results also at low number of re volutions. Further the knife carrier can be assembled with different cutting inserts. Press in device: | Hydraulic press-in device for optimum feeding of shredding material into rotor. Control system: | Via smart control with PLC control for protection of machine against damage at overload or massive parts. Stator carrier: | The innovation is the relocation of the stator carrier. This can be pivoted automatically for extraneous materials. Consequently extraneous material up to the size of a football can be ejected. Therefore a manual intervention is no longer necessary as for the already existing technology. For ejection of extrane ous materials there are different possible solutions. This is planned according to customer’s specification. Machine frame: | Heavy massive design of machine frame rotor and stator carrier are moved via a swivel shaft. Drive: | Mechanical drive with safety coupling. Variable rotational speed of rotor enables different applications. ERDWICH ZERKLEINERUNGSSYSTEME GMBH Kolpingstraße 8 | 86916 Kaufering | Tel.: +49(0) 81 91 / 96 52 - 0 | Fax: +49(0) 81 91 / 96 52 - 16 | E-Mail: infoline@erdwich.de | www.erdwich.co

Open the catalog to page 1

ERDWICH SINGLE-SHAFT-SHREDDER Technical Data Amount of stator knives Cutting unit size (LxW mm) Diameter of punched Width of rotor sieve (mm) knife* (mm) Cutting unit length A Cutting unit width B Subject to technical changes. ERDWICH ZERKLEINERUNGSSYSTEME GMBH Kolpingstraße 8 | 86916 Kaufering | Tel.: +49(0) 81 91 / 96 52 - 0 | Fax: +49(0) 81 91 / 96 52 - 16 | E-Mail: infoline@erdwich.de | www.erdwich.com

Open the catalog to page 2All ERDWICH Zerkleinerungs-Systeme GmbH catalogs and technical brochures

-

ERDWICH M468/2

2 Pages

-

CARDBOARD SHREDDING

2 Pages

-

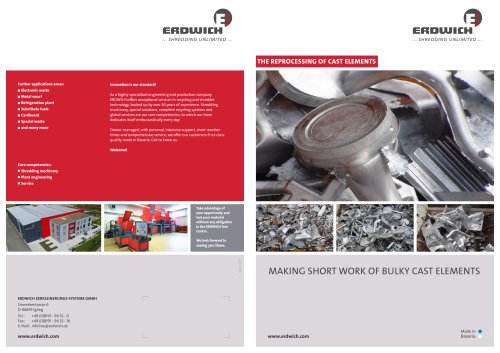

PROCESSING OF CAST PARTS

2 Pages

-

SUBSTITUTE fuel Processing

2 Pages

-

swarf shredding drum TSZ

2 Pages

-

Cardboard Shredder EKZ

2 Pages

-

Two-Shaft Shredder M468/2

2 Pages

-

Two-Shaft Shredder MH 480/2

2 Pages

-

Single-Shaft Shredder M700/1

2 Pages

-

Single-Shaft Shredder M600/1

2 Pages

-

Single-Shaft Shredder M400/1

2 Pages

-

Cardboard Shredder FKZ

2 Pages

-

Three-Shaft Shredder M465/3

2 Pages

-

Two-Shaft Shredder M465/2

2 Pages

-

Two-Shaft Shredder M450/2

2 Pages

-

Two-Shaft Shredder M350/2

2 Pages

-

Two-Shaft Shredder M250/2

2 Pages

-

Two-Shaft Shredder H500/2 SD

2 Pages

-

Two-Shaft Shredder H500/2

2 Pages

-

Ripper RM 1350

6 Pages

-

Metal Swarfs

8 Pages

-

LCD Processing

6 Pages

-

Image

11 Pages

-

Hammermill

6 Pages

-

ERDWICH TWO-SHAFT-RIPPER

2 Pages

-

WEEE PROCESSING

8 Pages

-

Hammer mill HA800

2 Pages