Catalog excerpts

INCREASE YOUR PRODUCTIVITY NOW! THE SPECIALIST FOR COARSE MATERIALS WHILST BEING INCREDIBLY GENTLE!

Open the catalog to page 1

TWO-SHAFT SYSTEM. PARTICULARLY GENTLE. HIGH EFFICIENCY. Our experience of over 30 years of manufacturing and developing shredding machines manifests itself again in this ripper technology which has been in use for several years. In combination with downstream hammer mills, granulators and separation technologies, we also offer complex turnkey plant engineering. The objective to obtain best results with a low drive power and to keep the costs of wearing parts as low as possible has been fully achieved with this technology. Technical highlights: Despite the most extreme stresses even with...

Open the catalog to page 2

The gentle ripper for processing the widest variety of materials. When processing the widest variety of materials, homogeneous break down of materials is of great importance, as is also a gentle size reduction process. DRIVES Different drive variants in compact design: With industrial or epicyclic gear unit and in high torque execution available It is in this area particularly, that the pre-shredder demonstrates its strengths. We are able to shred the material being processed so that the desired component size is obtained. This is achieved by our novel ripper technology, offering, in...

Open the catalog to page 3

SEGMENT BREAKDOWN being processed RIPPING TOOLS BULKHEAD WALL PARTITION DUCTS ■ For protecting the bearings from

Open the catalog to page 4

Size of cutting gear (L x W mm) Weight Drive power Technical data Cutting edge width Dimensions with compact gear unit Overall length A Width of cutting gear D Length of cutting gear E Height of cutting gear F Width of cutting gear D Length of cutting gear E Height of cutting gear F Dimensions with epicyclic gear unit

Open the catalog to page 5

ALL OF YOUR REQUIREMENTS ARE IN EXPERT HANDS WITH US. As an owner-managed company, we are able to offer you personal consulting, short reaction times and customized solutions. Combined, of course, with comprehensive services and first-class quality made in Bavaria. Core competencies: Shredding machines Plant engineering Service We look forward to your challenges. ERDWICH ZERKLEINERUNGSSYSTEME GMBH Kolpingstrasse 8 D-86916 Kaufering

Open the catalog to page 6All ERDWICH Zerkleinerungs-Systeme GmbH catalogs and technical brochures

-

ERDWICH M468/2

2 Pages

-

CARDBOARD SHREDDING

2 Pages

-

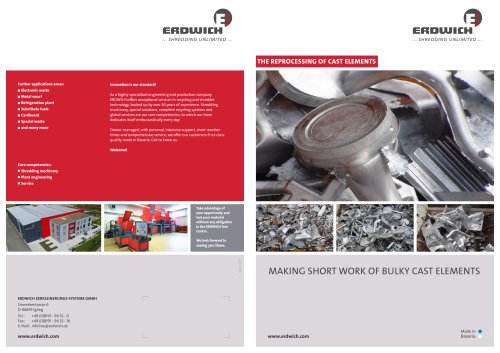

PROCESSING OF CAST PARTS

2 Pages

-

SUBSTITUTE fuel Processing

2 Pages

-

swarf shredding drum TSZ

2 Pages

-

Cardboard Shredder EKZ

2 Pages

-

Two-Shaft Shredder M468/2

2 Pages

-

Two-Shaft Shredder MH 480/2

2 Pages

-

Single-Shaft Shredder M700/1

2 Pages

-

Single-Shaft Shredder M600/1

2 Pages

-

Single-Shaft Shredder M400/1

2 Pages

-

Cardboard Shredder FKZ

2 Pages

-

Three-Shaft Shredder M465/3

2 Pages

-

Two-Shaft Shredder M465/2

2 Pages

-

Two-Shaft Shredder M450/2

2 Pages

-

Two-Shaft Shredder M350/2

2 Pages

-

Two-Shaft Shredder M250/2

2 Pages

-

Two-Shaft Shredder H500/2 SD

2 Pages

-

Two-Shaft Shredder H500/2

2 Pages

-

Single-Shaft Shredder M800/1

2 Pages

-

Metal Swarfs

8 Pages

-

LCD Processing

6 Pages

-

Image

11 Pages

-

Hammermill

6 Pages

-

ERDWICH TWO-SHAFT-RIPPER

2 Pages

-

WEEE PROCESSING

8 Pages

-

Hammer mill HA800

2 Pages