Catalog excerpts

Mechanized Rock Excavation with Atlas Copco – No 1 / 2014. Colombian hydro in full swing Dramatic rescue for Turkey’s ancient shrine A champion for the next Winter Olympics New Scooptram ST18 gets top marks

Open the catalog to page 1

he mining industry is facing some tough challenges these days. Investments have slowed down and companies are reluctant to mine certain minerals such as gold due to a decline in market prices. As a result, the focus today is on productivity and cost control – and that’s where Atlas Copco is lending a helping hand. As one of the world’s leading suppliers of rock drilling tools, we have a responsibility to develop a constant stream of innovative products that can meet our customers’ needs and support them in their efforts to achieve their tough objectives. In fact, the demand for our...

Open the catalog to page 2

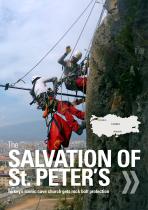

TURKEY Antioch salvation of St. Peter’s Turkey’s iconic cave church gets rock bolt protection Mining & Construction – 1 / 2014

Open the catalog to page 3

Above: The rescue team working for Turkish contractor Kuzey Dagcılık line up for a photo to commemorate the completion of their successful mission. Swellex to the rescue: These mountaineers had to abseil down the mountainside to reach the section of loose and crumbly rock that threatened to fall on the famous cave church of St. Peter’s. Atlas Copco’s Deyvi Akkris and Bahadir Ergener, Sales Engineer and Business Line Manager, instruct the team on how to install the Swellex Pm24. Right, the APSP 300 Swellex pump is hoisted into position. The Church of Saint Peter near the city of Antioch in...

Open the catalog to page 4

Since its introduction in the 1980s, the Swellex rock bolting system has gained wide recognition in mining and tunnelling. This unique bolt is made of a welded tube folded on itself and sealed at one end. This enables a strong anchorage to be achieved through a combination of friction from radial pressure and mechanical interlocking from profile deformation. The bolts are expanded with high pressured water (300 bar). For St. Peter’s Church, 3 and m 3.6 m plastic coated Pm24 Swellex rock bolts were chosen. This model starts to elongate at a pressure of 20 t and is fully load bearing after...

Open the catalog to page 5

Raiseborer stars in major tunnel project for Winter Games 2018 As the winter Olympics in Sochi came to its spectacular close, athletes and sports fans alike were already setting their sights on the next Olympian challenge – and so were the engineers and ventilation specialists at SungPoong Construction. he Winter Olympics 2018 are to be held in PyeongChang, South Korea, and a new super highway will enable the world’s sports fans to travel to and from the venue quickly and safely. One of the key elements of the project is the construction of the Inje Tunnel, which at 10.9 km long will be the...

Open the catalog to page 6

Above the tunnel: Engineers at SungPoong Construction adjust the settings on the Atlas Copco Robbins raiseborer. Inside the tunnel: The reamer head starts to ream up the hole to a diameter of 3.1 m after completion of the 12 ¼ inch pilot hole. High quality and long life: Left, Magnum cutter G and Magnum cutter N (right) after reaming the 307 m shaft. An Olympian achievement: High above the Inje Tunnel in the mountains of Kangwondo, South Korea, the Robbins 73 RVF C raiseborer was used to bore two ventilation shafts, 212 m and 307 m in length, each with a diameter of 3.1 m, later to be...

Open the catalog to page 7

China moving on… …from pneumatics to hydraulics In the ancient city of Suizhou, many things have stayed the same for thousands of years, but not the way the local drillers operate. These days, hydraulics is getting the better of pneumatics. Atlas Copco’s PowerROC T25 DC drill rig, made in Japan, is convincing Chinese customers of the wisdom of making the transition from pneumatic to hydraulically controlled equipment. he city of Suizhou in China’s northern province of Hubei, is well known as the hometown of the ancient Chinese emperors Yandi-Shennong and Huangi. It is also the home of...

Open the catalog to page 8

Ituango Project Zone Medellin Bogotá Good Energy Colombia’s Future It’s been over 30 years since it was first planned, but once in operation, the Ituango hydroelectric plant will be the largest in Colombia, generating 2 400 MW or around 17 percent of the country’s energy needs. A large and diverse fleet of equipment, strengthened by onsite service maintenance and drill steel supply, is helping this project to finally become a reality. Mining & Construction – 1 / 2014

Open the catalog to page 9

Heading up a world class fleet: The Atlas Copco three-boom drill rig, Boomer XE3 C, at work in the 240 m long powerhouse cavern where some 270 000 m 3 of rock is to be excavated. It is one of seven Boomer rigs being used on the project. hase I of the Ituango hydropower project consisted of preliminary construction work including an access road to the site, a river diversion and an access tunnel to the underground area. Phase II comprises the main civil engineering works being handled by CCC Ituango, a consortium formed by Brazil’s Camargo Correa and Colombian firms Constructora Conconcreto...

Open the catalog to page 10

Taming the waters of the Cauca Canyon Rugged green peaks and stunning views in every direction. This is the first impression that hits any visitor to Colombia’s north-western Antioquia region where construction of the Ituango Hydroelectric Project is now in full swing. Colombia currently has 14 000 MW of installed electricity generating capacity and when it comes on stream in 2020, the new Ituango plant will add a further 2 400 MW to the grid. “This project is a huge responsibility for everyone involved and is expected to provide enough energy to meet the growth in demand for at least the...

Open the catalog to page 11

On site: An XAS 375 portable compressor and (right) a QLT M10 lighting tower. excavation of approximately 270 000 m3. After passing through the turbines, the water will flow downstream to the surge chambers and then discharge into the Cauca River via four tailrace tunnels, two from each surge chamber about 1 400 m downstream from the intake site. New drilling fleet The new Atlas Copco fleet at Ituango includes seven Boomer drill rigs of various models with one, two or three-booms; 15 FlexiROC T35 drill rigs; four Diamec 262 (now Diamec U6) core drilling rigs, three Scooptram ST2G loaders;...

Open the catalog to page 12All Epiroc catalogs and technical brochures

-

Boltec 235

5 Pages

-

Boomer E3/E4 series

5 Pages

-

ST1030

8 Pages

-

Boltec S

8 Pages

-

Boltec M

5 Pages

-

Boltec E

5 Pages

-

T20R

5 Pages

-

FlexiROC T15 R

5 Pages

-

Boomer S1 L

8 Pages

-

Explorac 235

5 Pages

-

Explorac 100

5 Pages

-

Mining & Construction 2014_2

44 Pages

-

Mining & Construction 2013_3

40 Pages

-

Mining & Construction 2013_2

40 Pages

-

Mining & Construction 2013_1

36 Pages