Website:

EPILOG LASER

Website:

EPILOG LASER

Catalog excerpts

Guidebook to Starting Your Own Engraving and Cutting Business

Open the catalog to page 2

From smart boards to tablets, 3D printers to laser cutters, more and more schools are bringing hands-on, interactive technology to the classroom. Whether it is an industrial technology course, art lab, or a makerspace, schools and universities incorporating new technology in the classroom are engaging more students and creating active learners. Laser cutting/engraving systems are fast becoming one of the most in-demand tools to add to the classroom, or in some cases, build an entire curriculum around. Laser cutters are versatile, easy to use, and safe. Not to mention incredibly fun to use....

Open the catalog to page 3

EDUCATIONAL MAKERSPACES What is a makerspace? It’s a space that is designed for your students to access technology products that they can use to learn and create. Some makers spaces are just starting out and will have a supply of electronics for students to use to tinker with. Others are more advanced and established, offering students access to CNC routers, 3D printers, welding equipment, laser cutters (and more!). Each offer students a great resource to further their creativity. School Makerspace Benefits • Taking Products from Ideas to Reality Technology has taken on a new importance in...

Open the catalog to page 4

HIDDEN BENEFITS OF A LASER The versatility of the laser means that there are naturally some hidden benefits to incorporating this type of equipment in your school. It’s up to your discretion if you want to share all of these money saving ways to use the laser outside the classroom, or if you want to keep them to yourself! Awards and Plaques There are numerous awards that your school gives out every year - why not create your own custom awards and trophies with the laser? Creating and producing custom awards can be expensive. Bringing these services in house can have a positive impact on...

Open the catalog to page 5

COMPARING LASER SYSTEMS The first question you (or perhaps your administration) may have is, why the wide variety of pricing in laser systems? The biggest difference you’ll see in an inexpensive system and an Epilog Laser is the quality of the components and support available from Epilog. Epilog’s laser source and motion control components results in much faster engraving and cutting times, and much higher quality of etching. We want to make sure you are up and running constantly with the laser! Glass vs. Metal Laser Tubes When you see an extremely inexpensive laser online, there’s a good...

Open the catalog to page 6

SETTING UP LASER POLICIES Makerspaces differ in their policies for using their laser systems; however, the vast majority - at minimum - require an introductory course that explains how the laser works, how to send jobs to the laser, what materials work with the laser, how to clean the laser, etc. Some makerspaces cover this important information in one introductory course, while others break it into two or three more in-depth sessions. EASE OF MAINTENANCE All laser systems will need maintenance. There are complicated electronics and components within this system that need to be maintained...

Open the catalog to page 7

WHAT ELSE DO I NEED TO GET STARTED? An important question to ask is, what is included with my system, and what else will I need to get up and running with the laser? • A Laser System Laser systems range from $8,000 to around $65,000 based on engraving area and the wattage of the laser system. Later we’ll discuss lease-to-own options andwhatwattage is rightforyourneeds. • A Computer Any Windows XP, Vista, 7, 8, or 10 operating system is recommended. All of the versions of 2000, XP, and Vista (Home, Professional, etc.) are compatible with an Epilog Laser system. • Graphic Software Epilog’s...

Open the catalog to page 8

Guide for Lasers in Education

Open the catalog to page 9

WHY WILL THE LASER BE THE MOST POPULAR TOOL AT MY SCHOOL? When the votes come in, you’ll quickly see why the laser is frequently cited by schools as the most popular tool in their class rooms or makerspaces. The system’s popularity stems from a combination of the ease of use of the system and the versatility of materials you can work with. While 3D printers may get more ‘wow’ factor initially, students tend to spend the majority of their time on the laser system. Ease of Use The popularity of the laser can be an important consideration when deciding where to spend your budget. The higher...

Open the catalog to page 10

CURRICULUM IDEA 1: CREATE A CUSTOM KEYCHAIN Project Description: For a first laser project, a keychain can be a quick and easy way to learn many of the essential basic lessons needed on all future projects. Have the students take a piece of wood and design a keychain using their own custom design. Material Needs: • Wood sheets • Keychain Rings Concepts Covered: • Setting up a basic laser project • Page setup • Creating a vector cut line (vector vs. raster discussion) • Importing a graphic • Using the laser’s print driver • Material settings • Sending a job to the laser CURRICULUM IDEA 2:...

Open the catalog to page 11

Project Description: Lasers are increasingly being used in fashion design, including direct to fabric engraving and creating intricate cut-out patterns. Have students find a piece of old clothing - their own or from a thrift store-that they can customize with the laser! Material Needs: • Old clothing, shoes, etc. from home or from a thrift store Concepts Covered: • Working with resolution on different materials • What materials engrave best with a laser? Project Inspirations: • Laser etch jeans with a pattern that is repeated throughout the material. • Laser engrave a design on leather...

Open the catalog to page 12

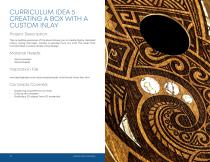

CURRICULUM IDEA 5: CREATING A BOX WITH A CUSTOM INLAY Project Description: The incredible precision of the laser allows you to create highly-detailed inlays. Using this idea, create a wooden box cut with the laser that incorporates a wood veneer inlay design. Material Needs: • • Wood veneers Wood sheets CURRICULUM IDEA 6: CREATING A PROTOTYPE Project Description: Taking all of the concepts learned in the laser classes, create a finished prototype. This can incorporate multiple materials Material Needs: • Scrap materials: wood, acrylic, plastics, etc. • Electronics: Arduino and Raspberry Pi...

Open the catalog to page 13All EPILOG LASER catalogs and technical brochures

-

FusionSeries

294 Pages

-

Product Line Brochure

9 Pages

-

Customize Sporting Goods

2 Pages

-

Laser Metal Marking

2 Pages

-

Promotional products

2 Pages

-

Engrave & Cut fabric

2 Pages

-

Start Your Own Business

15 Pages

-

EPILOG'S FIBER LASER

29 Pages

-

Job Manager Flyer

2 Pages

-

eView Camera Module

2 Pages

-

G2 Brochure

2 Pages

-

Woodworking

2 Pages

-

CO2 Metal Marking

2 Pages

-

Fusion 40

2 Pages

-

Laser Engraving

2 Pages

-

FiberMark Brochure

7 Pages

-

Zing Laser Starter Series

3 Pages

Archived catalogs

-

Fusion M2 32

2 Pages

-

EXT Technical Specifications

2 Pages

-

Metal Working Guide

4 Pages

-

Wood Working Guide

4 Pages