Website:

EPILOG LASER

Website:

EPILOG LASER

Catalog excerpts

EPILOG'S FIBER LASER G INDUSTRIAL ETCHING & MARKING

Open the catalog to page 1

Fiber Laser Industrial Etching & Marking © 2017 Epilog Laser 1

Open the catalog to page 2

HOW A FIBER LASER WORKS The Short Answer: The fiber laser source generates a laser beam by pumping intense diode light into the end of fiber optic cables that have been doped with ytterbium. The energy from the diode light is absorbed by the ytterbium in the fiber optic cables. The ytterbium then releases the energy in the form of photons that travel down the optic cables. The photons that leave the optic cables create the laser beam. The wavelength of light generated from a fiber laser is 1062 nm. The Longer Answer: The fiber laser source generates laser light by pumping intense diode...

Open the catalog to page 3

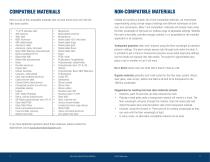

COMPATIBLE MATERIALS NON-COMPATIBLE MATERIALS Here is a list of the compatible materials that we have found work well with the fiber laser system: Instead of providing a master list of non-compatible materials, we recommend experimenting using a broad range of settings and different techniques to draw your own conclusions. Many “non-compatible” materials will actually mark using the fiber wavelength of light and our endless range of adjustable settings. Whether the mark is desirable, provides enough contrast, or is acceptable for the intended application is all subjective. 17-4 PH stainless...

Open the catalog to page 4

COMMONLY MARKED PRODUCTS Terminology used when examining different types of marks: How do customers most often use a fiber laser for their business? Many enter the market with one application in mind for use with the laser, but quickly expand the laser’s usage into a variety of different applications. Ablation: The process of ablation is the removal from the surface of an object by vaporization. You’ll often hear of this process associated with etching an anodized material. Annealing: This is the process of heating steel to a high temperature, creating a permanent oxide layer on the...

Open the catalog to page 5

2. Open Architecture Print Driver Benefits of Proprietary Software: • Guaranteed to work with the laser system regardless of updates. • Features that are specially designed for processes that are associated with the laser. Drawbacks of Proprietary Software: • Tries to recreate functions that are better handled by professional software. • Updates and bug-fixes are company dependent. • Have to learn new software to operate the laser and spend time training new operators on how to run the software. Benefits of Open Architecture Software: • You are able to use the most commonly used software...

Open the catalog to page 6

HOW TO REDUCE OVERALL CYCLE TIMES Here are a few tips for reducing the overall cycle time when testing a material with the laser. Use a Galvo Laser: A galvo laser system uses a faster beam delivery system than a flying-optic system, so you can process parts in a shorter amount of time. The Epilog G2 Laser is a galvo laser system. GENERAL PROCESSING GUIDELINES Processing fiber laser system applications isn’t rocket science; however there are several tips and tricks to help provide the best possible results. Tools: A pair of calipers and a 7-10X loop. Checklist: Start by reviewing the system...

Open the catalog to page 7

BEAM DELIVERY OPTIONS There are two options for beam delivery in a fiber laser system: Flying-Optic and Galvo. Each has benefits and drawbacks. By examing the information below you can determine which is the right choice for your application. Flying-Optic Beam Delivery Systems Available: FiberMark 24 / Fusion M2 32 / Fusion M2 40 What is it? A flying-optic system utilizes a series of moving mirrors in the x- and y-axis Benefits: You can laser mark a large part up to 40" x 28" x12.25" (1016 x 711 x 311 mm) or fill the entire table with smaller parts and let the laser engrave the entire table...

Open the catalog to page 8

Q: What is the max material height? A:Flat Stock: FAQS ON FIBER LASER SYSTEMS Q: What is the laser source of the fiber laser source? A: The source is a fiber laser: a fiber optic cable that has been doped with ytterbium, a rare earth element. Q: Is it the same as a YAG (yttrium aluminum garnate) laser? A: It produces the same wavelength of light and same marks. YAG lasers require cooling and more maintenance. Q: What is the wavelength of the FM? A: 1062 nm. Q: Is the wavelength of light dangerous? A: Yes, especially to the operator’s eyes and will pass through common Lexan or glass...

Open the catalog to page 9

The contrast / brightness of marks achievable on the fiber laser are excellent and can often be much brighter than marks from a C02 laser. Taking the fiber laser out of focus by +.06" - .09" broadens the beam and produces a very bright mark on anodized coating. Lower frequency and higher power settings help offset the change in focal point. Different grades of anodized & core aluminum alloy will affect how the final marks look. 16 Fiber Laser Industrial Etching & Marking © 2017 Epilog Laser 17

Open the catalog to page 10

Two to three passes are suggested (one pass to ablate the powder coating, 2nd or 3rd pass to polish up the metal underneath). A little less power, higher frequency and less focus adjustment will be required for the 2nd or 3rd pass, depending on the base metal. The idea is to ablate then polish. An alternative to running two or more passes is to run one pass and then use a common cleaner such as Simple Green or a citric-based cleaner with short, stiff bristle brush to scrub out the residual material remaining in the mark area. If using this technique, it may be necessary to raise or lower...

Open the catalog to page 11

ANNEALING & POLISHING OF METALS ANNEALING METALS Annealing can be done on most metals that contain high levels of carbon and metal oxides. These are generally, but not limited to, steel alloys, iron, titanium, cobalt, molybdenum, and chrome-plated iron/steel. To anneal, you must use a slow rate of speed to heat and change the surface color of the material, but a higher wattage fiber laser system will help reduce the cycle times. that are more difficult to anneal, if there is inconsistent color change at the recommended settings, or when cycle times aren’t a concern. The extra overlapping of...

Open the catalog to page 12All EPILOG LASER catalogs and technical brochures

-

FusionSeries

294 Pages

-

Product Line Brochure

9 Pages

-

Customize Sporting Goods

2 Pages

-

Laser Metal Marking

2 Pages

-

Promotional products

2 Pages

-

Engrave & Cut fabric

2 Pages

-

Start Your Own Business

15 Pages

-

Job Manager Flyer

2 Pages

-

eView Camera Module

2 Pages

-

G2 Brochure

2 Pages

-

Woodworking

2 Pages

-

CO2 Metal Marking

2 Pages

-

Fusion 40

2 Pages

-

Laser Engraving

2 Pages

-

FiberMark Brochure

7 Pages

-

Zing Laser Starter Series

3 Pages

Archived catalogs

-

Fusion M2 32

2 Pages

-

EXT Technical Specifications

2 Pages

-

Metal Working Guide

4 Pages

-

Wood Working Guide

4 Pages