Catalog excerpts

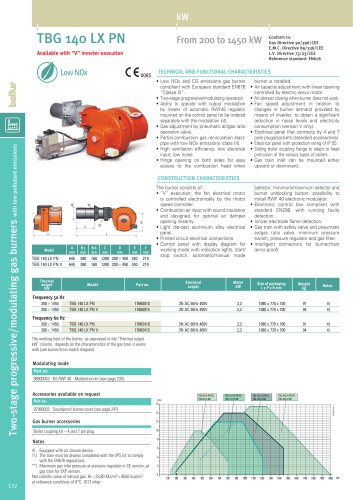

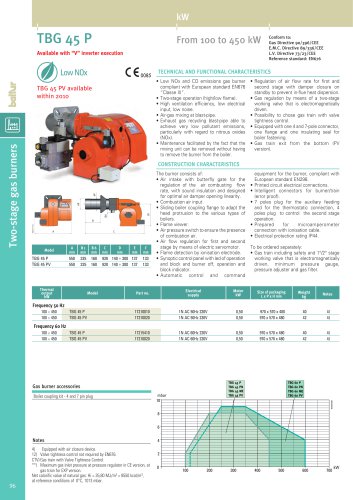

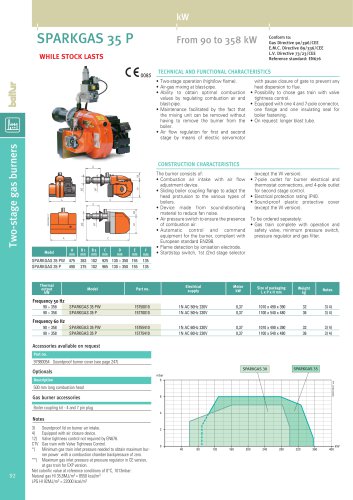

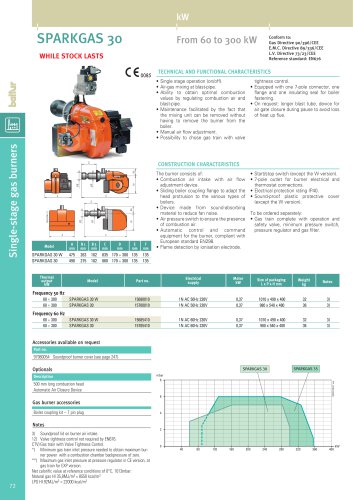

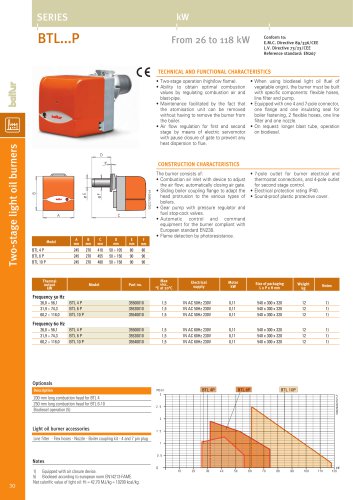

Available with “V” inverter execution The burner consists of: • Fan driven by light alloy three-phase electric motor. • “V” execution: the fan electrical motor is controlled electronically by the motor speed controller. • Combustion air input with sound insulation and designed for optimal air damper opening linearity. • Light die-cast aluminium alloy electrical panel. • Printed circuit electrical connections. • Control panel with display diagram for working mode with indication lights, start/ stop switch, automatic/manual mode Electrical supply burner is installed. • Air capacity adjustment with linear opening controlled by electric servo motor. • Air damper closing when burner does not work. • Fan speed adjustment in relation to changes in burner demand provided by means of inverter, to obtain a significant reduction in noise levels and electricity consumption (version V only). • Electrical panel that connects by 4 and 7 pole plugs/sockets (standard accessories). • Electrical panel with protection rating of IP 55. • Sliding boiler coupling flange to adapt to head protrusion of the various types of boilers. • Gas train inlet can be mounted either upward or downward. selector, minimum/maximum selector and burner unblocking button; possibility to install RWF 40 electronic modulator. • Electronic control box compliant with standard EN298, with running faults detection. • Ionizer electrode flame detection. • Intelligent connectors for burner/train (error proof). To be ordered separately: • Gas train with safety valve and pneumatic air/gas ratio valve, minimum pressure switch, pressure regulator and gas filter. The working field of the burner, as expressed in the “Thermal output kW” column, depends on the characteristics of the gas train it works with (see burner/train match diagram). Modulating mode Part.no 98000053 Kit RWF 40 - Modulation kit (see page 230). Accessories available on request 97980053 Soundproof burner cover (see page 247) Gas burner accessories Boiler coupling kit – 4 and 7 pin plug 4) Equipped with air closure device. 12) Valve tightness control not required by EN676. **) Maximum gas inlet pressure at pressure regulator in CE version, at gas train for EXP version. Net calorific value of natural gas: Hi = 35,80 MJ/m3 = 8550 kcal/m3, at reference conditions of 0°C, 1013 mbar. TECHNICAL AND FUNCTIONAL CHARACTERISTICS • Low NOx and CO emissions gas burner compliant with European standard EN676 “Classe III”. progressive/modulating • Two-stage operation. • Ability to operate with output modulation by means of automatic RWF40 regulator mounted on the control panel (to be ordered separately with the modulation kit). • Gas adjustment by pneumatic air/gas ratio operation valve. • Partial combustion gas recirculation blastpipe with low NOx emissions (class III). • High ventilation efficiency, low electrical input, low noise. • Hinge opening on both sides for easy access to the combustion head when Two-stage progressive/modulating gas burners with low pollutant emissions Conform to: Gas Directive 90/396/CEE E.M.C. Directive 89/336/CEE L.V. Directive 73/23/CEE Reference standard: EN676

Open the catalog to page 1

Burner/gas train match CE gas train version complies with EN676, EXP gas train version is for extra-European markets Gas type Curve on Execution P.Max** graph mbar Regulator with incorporated filter Part no. Included Included Included Included Included Included Included Included Included Included To choose the correct gas train please refer to the information on page 10. For information on the structure, composition, and size of the gas train please refer to the diagrams on page 234. Pressurecarico (combustion head + Perdite di drop (testa di combustione + regulator) gas train +...

Open the catalog to page 2All EOGB energy products ltd catalogs and technical brochures

-

TBG 140 LX PN

2 Pages

-

SparkGas 30 LX

2 Pages

-

GI 510 DSPGN

2 Pages

-

GI 350 DSPGN

2 Pages

-

BTG 28 ME

2 Pages

-

TBG 45 P

2 Pages

-

TBG 35 P

2 Pages

-

SparkGas 35 P

2 Pages

-

SparkGas 30 P

2 Pages

-

TBG 45

2 Pages

-

TBG 60

2 Pages

-

TBG 35

2 Pages

-

SparkGas 35 (BGS 35)

2 Pages

-

SparkGas 30 (BGS 30)

2 Pages

-

BTG

8 Pages

-

GI 1000 DSPG

1 Pages

-

GI

1 Pages

-

Low NOx models

1 Pages

-

BT

2 Pages

-

Spark 35 DSG

1 Pages

-

XSeries Burners

2 Pages