Website:

EOGB energy products ltd

Website:

EOGB energy products ltd

Catalog excerpts

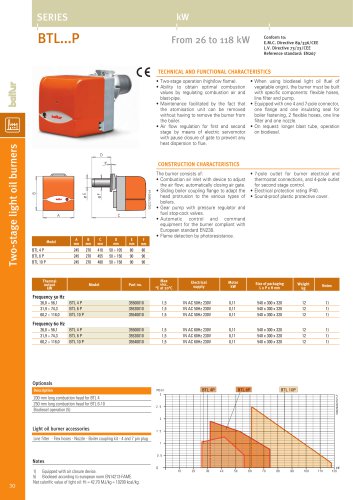

TECHNICAL AND FUNCTIONAL CHARACTERISTICS • Low NOx and CO emissions gas burner compliant with European standard EN676 “Class III”. • Single stage operation (on/off). • High ventilation efficiency, low electrical input, low noise. • Air-gas mixing at blast-pipe. • Exhaust gas recycling blast-pipe able to achieve very low pollutant emissions, particularly with regard to nitrous oxides (NOx). • Maintenance facilitated by the fact that the mixing unit can be removed without having to remove the burner from the boiler. • Manual air flow adjustment. • Gas regulation by means of a two-stage working valve that is electromagnetically driven. • Possibility to chose gas train with valve tightness control. • Equipped with one 7-pole connector, one flange and one insulating seal for boiler fastening. • Gas train exit is possible either from the top or from the bottom. CONSTRUCTION CHARACTERISTICS Conform to: Gas Directive 90/396/CEE E.M.C. Directive 89/336/CEE L.V. Directive 73/23/CEE Reference standard: EN676 The burner consists of: • Combustion air intake with air flow adjustment device. • Sliding boiler coupling flange to adapt the head protrusion to the various types of boilers. • Flame viewer. • Air pressure switch to ensure the presence of combustion air. • Manual air flow adjustment. • Flame detection by ionisation electrode. • Synoptic control panel with led of operation and block and burner off, operation and block indicator. • Automatic control and command equipment for the burner, compliant with Electrical supply European standard EN298. • Printed circuit electrical connections. • Intelligent connectors for burner/train (error proof). • 7 poles plug for the auxiliary feeding and for the thermostatic connection. • Prepared for microamperometer connection with ionisation cable. • Electrical protection rating IP44. To be ordered separately: • Gas train including safety and 1°/2° stage working valve that is electromagnetically driven, minimum pressure gauge, pressure adjuster and gas filter. Gas burner accessories Boiler coupling kit - 7pin plug 12) Valve tightness control not required by EN676. CTV) Gas train with Valve Tightness Control. **) Maximum gas inlet pressure at pressure regulator in CE version, at gas train for EXP version. Net calorific value of natural gas: Hi = 35,80 MJ/m3 = 8550 kcal/m3, at reference conditions of 0°C, 1013 mbar.

Open the catalog to page 1

Burner/gas train match CE gas train version complies with EN676, EXP gas train version is for extra-European markets Gas type Curve on Execution P.Max** graph mbar P.Min* mbar Regulator with incorporated filter Part no. Valve tightness control kit Part no. Valve tightness control kit Part no. Burner/gas train adapter Part no. Included 96000005 Included 96000005 Included 96000004 Included 96000004 Included 96000004 Included 96000004 Included – Included – Included 96000013 Included 96000013 Included 96000005 Included 96000005 Included 96000004 Included 96000004 Included 96000004 Included...

Open the catalog to page 2All EOGB energy products ltd catalogs and technical brochures

-

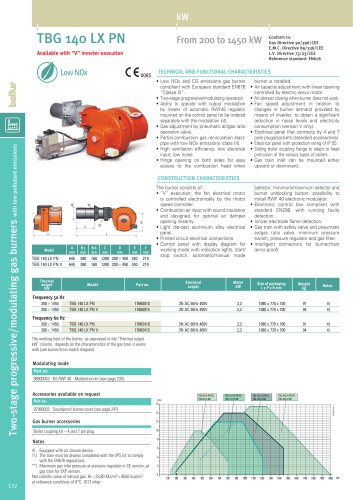

TBG 140 LX PN

2 Pages

-

TBG 80 LX PN

2 Pages

-

SparkGas 30 LX

2 Pages

-

GI 510 DSPGN

2 Pages

-

GI 350 DSPGN

2 Pages

-

BTG 28 ME

2 Pages

-

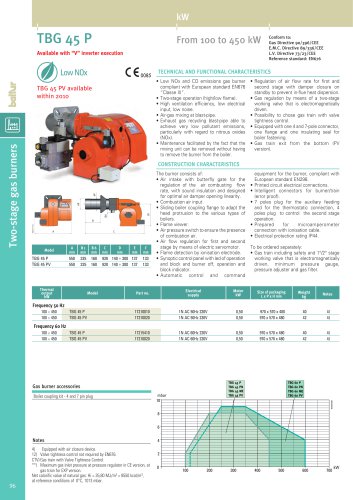

TBG 45 P

2 Pages

-

TBG 35 P

2 Pages

-

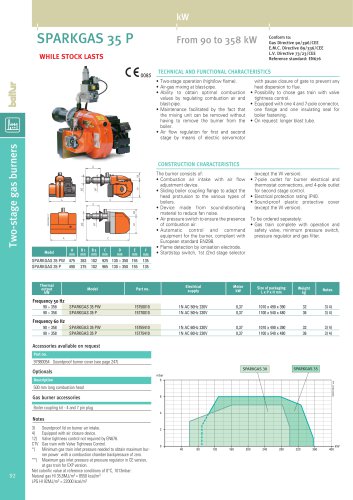

SparkGas 35 P

2 Pages

-

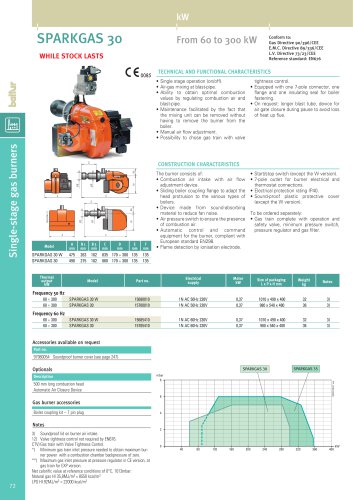

SparkGas 30 P

2 Pages

-

TBG 60

2 Pages

-

TBG 35

2 Pages

-

SparkGas 35 (BGS 35)

2 Pages

-

SparkGas 30 (BGS 30)

2 Pages

-

BTG

8 Pages

-

GI 1000 DSPG

1 Pages

-

GI

1 Pages

-

Low NOx models

1 Pages

-

BT

2 Pages

-

Spark 35 DSG

1 Pages

-

XSeries Burners

2 Pages