Website:

EOGB energy products ltd

Website:

EOGB energy products ltd

Catalog excerpts

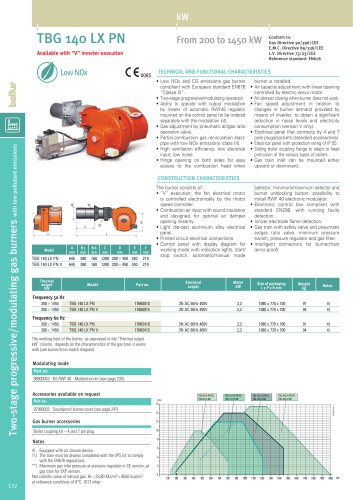

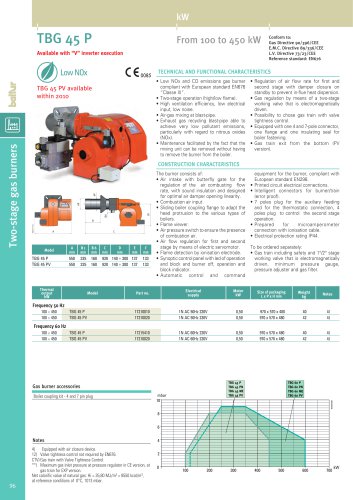

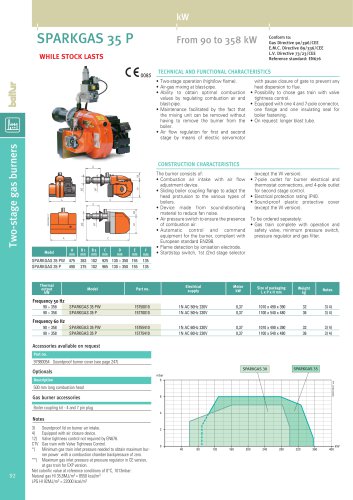

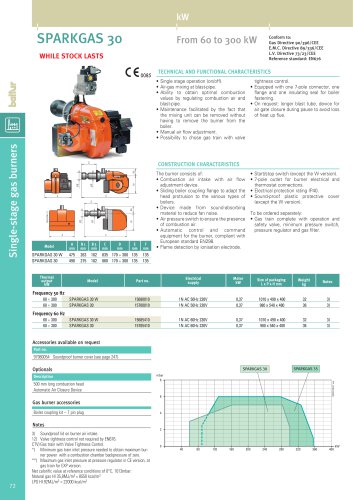

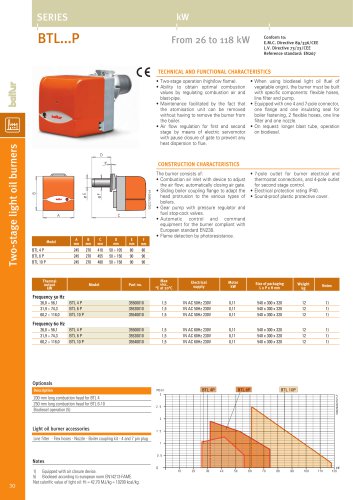

TECHNICAL AND FUNCTIONAL CHARACTERISTICS • Two-stage progressive output operation. european norm EN676). • Ability to operate with output modulation • Capacity regulation of the combusting air by means of automatic RWF40 regulator with automatic closing gate during pause mounted on the control panel (to be to avoid heat losses at the chimney. ordered separately with the modulation • Maintenance facilitated by the fact that kit). the mixing unit can be removed without • Air-gas mixing at blast-pipe. having to remove the burner from the • Ability to obtain optimal combustion boiler. values by regulating combustion air and • With valve tightness control. blast-pipe. • Equipped with one flange and one • Combustion head at partial recycle of insulating seal for boiler fastening, combusting gas which allow to achieve one 4-pole connector and one 7-pole low NOx emissions (Class II of the connector. CONSTRUCTION CHARACTERISTICS Electrical supply sequence and error code in the event of a lockout. • Flame presence check by ionisation electrode with connector for milliammeter. • 7-pole outlet for burner electrical and thermostat connections, and 4-pole outlet for second stage control. or of the capacity electronic regulator. • Electrical protection rating IP40. • Sound-proof plastic protective cover. To be ordered separately: • Gas train made up of a butterfly valve controlled by an electric pitch-pitch servomotor, by a monoblock valve which include an operating and safety valve, min.pressure switch, valve tightness control, pressure regulator and gas filter. The burner consists of: • Air intake with butterfly gate for the regulation of the air combusting flow rate. • Sliding boiler coupling flange to adapt the head protrusion to the various types of boilers. • Flame viewer. • Air pressure switch to ensure the presence of combustion air. • Regulation of the air combusting flow rate by means of an electric pitch-pitch servomotor. • Electronic control box compliant with standard EN298, with microprocessor (electronic cam), integrated valves’ tightness control; suitable for eBus connection. Display for operating Modulating mode Part.no 98000052 Kit RWF 40 - Modulation kit (see page 230). Two-stage progressive/modulating gas burners with electronic cam Conform to: Gas Directive 90/396/CEE E.M.C. Directive 89/336/CEE L.V. Directive 73/23/CEE Reference standard: EN676 Gas burner accessories Boiler coupling kit, 4 and 7 pin plug. 4) Equipped with air closure device. 13) Equipped with valve tightness control. *) Minimum gas train inlet pressure needed to obtain maximum burner power with a combustion chamber backpressure of zero. **) Maximum gas inlet pressure at pressure regulator in CE version, at gas train for EXP version. Net calorific value at reference conditions of 0°C, 1013mbar: Natural gas HI 35,8MJ/m3 = 8550 kcal/m3 LPG HI 92MJ/m3 = 22000 kcal/m3

Open the catalog to page 1

Burner/gas train match CE gas train version complies with EN676, EXP gas train version is for extra-European markets Burner model P.Max** mbar Regulator with incorporated filter Part no. Included Included Burner/gas train adapter Part no. Valve tightness control kit Part no. Included Included P.Min* mbar Regulator with incorporated filter Part no. Burner/gas train adapter Part no. Valve tightness control kit Part no. Burner model Pressurecarico (combustion head + Perdite di drop (testa di combustione + regulator) gas train + pressure rampa BTG 28ME Natural gas metano CE/EXP Two-stage...

Open the catalog to page 2All EOGB energy products ltd catalogs and technical brochures

-

TBG 140 LX PN

2 Pages

-

TBG 80 LX PN

2 Pages

-

SparkGas 30 LX

2 Pages

-

GI 510 DSPGN

2 Pages

-

GI 350 DSPGN

2 Pages

-

TBG 45 P

2 Pages

-

TBG 35 P

2 Pages

-

SparkGas 35 P

2 Pages

-

SparkGas 30 P

2 Pages

-

TBG 45

2 Pages

-

TBG 60

2 Pages

-

TBG 35

2 Pages

-

SparkGas 35 (BGS 35)

2 Pages

-

SparkGas 30 (BGS 30)

2 Pages

-

BTG

8 Pages

-

GI 1000 DSPG

1 Pages

-

GI

1 Pages

-

Low NOx models

1 Pages

-

BT

2 Pages

-

Spark 35 DSG

1 Pages

-

XSeries Burners

2 Pages