Catalog excerpts

Patented self cleaning gas sampling probe for continuous measurement in any high dust and high temperature process DEVELOPED AND MANUFACTURED IN GERMANY

Open the catalog to page 1

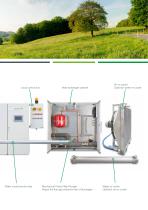

Probe rotary drive, rotates +/- 45° to prevent thermal probe deformation and sticking Moving e-chain - protects cables and hoses from wear and tear PLC cabinet with HMI (analysis optional) CEMTEC oven sealmechanical, maintenance-free

Open the catalog to page 2

Water cooled probe tube Heat exchanger cabinet Mechanical Probe Filter Plunger Keeps the flue gas entrance free of blockages Air re-cooler Optional: water re-cooler Water re-cooler Optional: air re-cooler

Open the catalog to page 3

SYSTEM CONFIGURATION CEMTEC provides low maintenance operation in cement kilns or in applications with high temperatures and / or high dust loads. The patented CEMTEC consists of a water-cooled gas sampling probe, which is mounted on a pneumatic propulsion device and travels in and out of the combustion process. The process gas is sucked into the filter unit through the tip of the cooling protection tube, and then into the centrally positioned measuring chamber. > CEMTEC gas sampling probe > Local control box > PLC cabinet with / without analysis > Heat exchanger cabinet > COMTEC InSitu...

Open the catalog to page 4

Process temperature up to 1400°C, dust concentrations of up to 2000 g/m³, high mechanical stress due to falling material and high ambient temperatures make extremely high demands on any technology in use. Thanks to the mechanical cleaning, the continuous extraction and analysis of process gas is possible over a long period of time. The dust filter with its impact plate at the tip is coaxially mounted within the cooling protection tube and moves in programmable intervals out of the tip of the cooling protection tube to remove any dust deposits. The patented CEMTEC rotary drive prevents...

Open the catalog to page 5

PERMANENT PROCESS CONTROL CEMTEC was developed for continuous analysis of flue gas in rotary kilns and other pyro processes with extremely dusty high-temperature processes with the goal of increasing product quality with a reduced fuel use while simultaneously reducing harmful emissions. Particularly in view of the increasing usage of alternative fuels in rotary kilns and large combustion chambers, the on-site gas analysis has become ever more important. With its exclusive technical highlights, CEMTEC provides an optimal solution for permanent measurement under these challenging conditions....

Open the catalog to page 6

TECHNICAL DETAILS SWIVEL DRIVE PROBE INSERTION DEPTH MEASURING RANGES PROBE DIAMETER PROBE COOLANT PROBE PROPULSION EMERGENCY RETRACTION Heat exchanger Cabinet Air re-cooler (Option: Water re-cooler) PLC and Control Panel in Analyzer Cabinet Analog and Digital Values for DCS Compressed Air Cooling Water - Hot Cooling Water - Cold Electrical Connections Sample Gas Line Connecting Flange CEMTEC Probe with E-Chain Oven Flap

Open the catalog to page 7

SAFE AND CLEAN COMBUSTION COMPANY SYSTEM FEATURES ENOTEC has provided gas sensing solutions since 1980, producing products with a high degree of accuracy, quality and durability - Made in Germany. Our flexibility allows us to quickly develop solutions individually designed to meet your requirements. On request, we also offer after delivery service concepts - the world over. > Rotary drive > Automated self cleaning > Mechanical cleaning > Emergency retraction > Integrated O2 / COe InSitu analysis > Air or water heat exchanger > High quality workmanship info@enotec.com www.enotec.com ENOTEC...

Open the catalog to page 8All ENOTEC GmbH catalogs and technical brochures

-

CEMTEC®

2 Pages

-

ENSITU® 7000

2 Pages