Catalog excerpts

Electric. Efficient. Compact & precise. ENGEL e-mac

Open the catalog to page 1

Best-in-class efficiency and precision to the max. All of the ENGEL e-mac‘s movements are performed by servo-electric drives. The all-electric drive helps you to achieve best-in-class efficiency for the entire machine. Maximum precision of all movements and impressive process stability guarantee the highest levels of good parts. e-mac ENGEL e-mac. ENGEL e-mac. A machine that gives you more. A machine that combines great performance with amazing precision. All-electric. A machine that offers you a huge amount of freedom. Enough freedom to be able to design your individual injection moulding...

Open the catalog to page 2

The ENGEL e-mac clamping unit. Close to perfection. High precision, dynamic clamping drive ensures short dry-cycle times and impressive productivity. And perfect integration with take-off units Sensitive mould protection. Protection against mould wear. For improved availability. ENGEL autoprotect. Automatic mould height determination. Automatic mould height determination on the ENGEL e-mac saves tooling time and prevents incorrect settings. For each mould change. The mounting height of the mould is automatically determined by an intelligent program. Linear guidance of the moving platen. The...

Open the catalog to page 3

The ENGEL e-mac injection unit. Inject the future. Powerful servo-motors. ensure high injection speeds and breathtaking acceleration. And: they allow for long, high post-injection pressures. High-precision sensors and fast control Highly precise and extremely fast - this is how the injection unit on the ENGEL e-mac works: for example, the screw position is measured by the encoders on the servo-motors. This ensures maximum resolution for highest precision and process assurance. Pressure membranes measure the peak, post-injection and holding pressures outside the nozzle area. This avoids the...

Open the catalog to page 4

Clamping drive: high productivity, precision and dynamic Short dry-cycle times for impressive productivity. This is what the dynamic clamping drive with its optimised toggle lever geometry offers. Due to FEM (Finite Element Method) optimised parts, only very little mass is moved. This improves the dynamic while at the same time reducing the energy consumption. Dynamic ejector - precise and dynamic Dry cycle time ENGEL e-mac 1,275 The ENGEL e-mac is equipped with a servo-electric ejector as standard equipment. This means that parallel motion of the ejector can be optimally adjusted to match...

Open the catalog to page 5

Long post-injection pressure – no problem! Long, high post-injection pressures can be a major challenge for electric machines. The motor and controller overheat after a short time at high pressures and the post-injection pressure collapses. The rule is: the more powerful the motor, the better the post-injection pressure behaviour. And here too the ENGEL e-mac sets new standards in its class. The powerful servo-motors can easily hold long post-injection pressures. Post injection pressure without time limit Injection unit Taking precision to the highest level High-quality sensors and fast...

Open the catalog to page 6

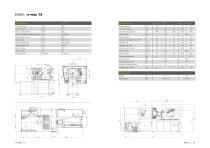

ENGEL | e-mac 50 Clamping unit Injection unit Clamping force Screw diameter Opening force Mould installation height min/max Screw stroke Stroke volume Injection part weight max. (PS) Mould fixing platen Injection rate Ejector stroke Nozzle contact force Nozzle stroke Plasticising capacity Screw speed Injection rate Premium Injection rate High Number of heating zones Installed heat output General data Weight Rated power ENGEL e-mac

Open the catalog to page 7

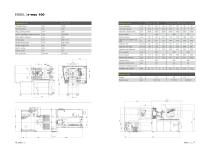

ENGEL | e-mac 75 Clamping unit Injection unit Clamping force Screw diameter Opening force Mould installation height min/max Screw stroke Stroke volume Injection part weight max. (PS) Mould fixing platen Injection rate Ejector stroke Ejector force Dry cycle time Injection rate High Injection rate Premium Screw speed Screw torque Plasticising capacity Nozzle stroke Nozzle contact force Rated power Installed heat output Number of heating zones ENGEL e-mac

Open the catalog to page 8

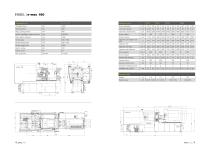

ENGEL | e-mac 100 Clamping unit Injection unit Injection unit 310 Injection unit 440 Clamping force Screw diameter Opening force Mould installation height min/max Screw stroke Stroke volume Mould fixing platen Injection part weight max. (PS) Injection rate Ejector stroke Ejector force Installed heat output General data Weight Rated power Number of heating zones Nozzle contact force Plasticising capacity Screw speed Injection rate High Injection rate Premium ENGEL e-mac

Open the catalog to page 9

ENGEL | e-mac 180 Clamping unit Injection unit Clamping force Screw diameter Opening force Mould installation height min/max Screw stroke Stroke volume Mould fixing platen Injection part weight max. (PS) Ejector stroke Ejector force Installed heat output Number of heating zones Nozzle stroke Nozzle contact force Plasticising capacity Screw torque Screw speed Injection rate Premium Injection rate High Injection rate General data Rated power ENGEL e-mac

Open the catalog to page 10

ENGEL e-mac ENGEL AUSTRIA GmbH | A-4311 Schwertberg | tel: +43 (0)50 620 0 | fax: +43 (0)50 620 3009 e-mail: sales@engel.at | www.engelglobal.com

Open the catalog to page 11All ENGEL AUSTRIA GmbH catalogs and technical brochures

-

press | release

4 Pages

-

ENGEL services

9 Pages

-

Plasticising unit

15 Pages

-

Composite Technologies

13 Pages

-

combimelt

15 Pages

-

automotive

19 Pages

-

Amorphous Metal Moulding

5 Pages

-

smart service

11 Pages

-

smart machine

15 Pages

-

Automation

41 Pages

-

engel AUTOMATIUON

15 Pages

-

ENGEL INSERT

15 Pages

-

Trining

11 Pages

-

protect

3 Pages

-

iQ weight control

2 Pages

-

Engel Flomo

16 Pages

-

Scope of products

29 Pages

-

CC300

7 Pages

-

e-motion 30 TL

8 Pages

-

ENGEL plus

2 Pages

-

ENGEL e-cap

3 Pages

-

ENGEL elast

11 Pages

-

ENGEL insert PRO

7 Pages

-

ENGEL combimelt

5 Pages

-

Customized Soft-Touch

3 Pages

-

Engel EXJECTION®

4 Pages

-

ENGEL e-factory

4 Pages

Archived catalogs

-

e-motion TL

9 Pages

-

ENGEL e-victory

17 Pages

-

ENGEL e-motion

17 Pages

-

ENGEL duo

19 Pages

-

ENGEL victory

15 Pages

-

ENGEL Control

8 Pages

-

ENGEL VIPER

13 Pages

-

speed injection moulding machine

10 Pages