Catalog excerpts

> Series ENGEL victory ENGEL e-motion ENGEL e-max ENGEL duo ENGEL speed ENGEL combimelt ENGEL insert ENGEL elast / Lim ENGEL PETsystems Integrative technology ENGEL robot ENGEL control Services ENGEL training ENGEL e-factory Application technology ENGEL application technology Industry sectors ENGEL automotive ENGEL teletronics ENGEL packaging ENGEL medical ENGEL technical moulding Summary ENGEL portfolio > Language german english french italian spanish czech chinese be the first. be the first. ENGEL AUSTRIA GmbH A-4311 Schwertberg tel: +43 (0)50 620 0 fax: +43 (0)50 620 3009 e-mail: sales@engel.at www.engelglobal.com 51030-0371/en/12-2008

Open the catalog to page 1

All electric, economical, a machine for the future. ENGEL e-max: > Maximum performance and process safety for very high productivity maximum > Maximum precision due to all electric drive technology with highly dynamic servomotors > Maximum energy efficiency ensures low power consumption > Maximum compactness: excellent performance in a small footprint High reliability thanks to highly-integrated control and drive technologies > High-performance injection units with peak pressures of up to 2800 bar and up to 450 mm/sec. injection speed > Versatile options ensure optimum customisation for any...

Open the catalog to page 2

precise Maximum precision means: the maximum number of good parts Maximum precision means: ENGEL e-max. Maximum precision. Part after part Maximum precision is required for plugs, contact strips, lenses, medical parts, and other top-quality products. The ENGEL e-max is perfectly geared for this. Thanks to all electric drive technology with highly dynamic servomotors. And also thanks to the high plasticizing precision of the injection unit and the extremely precise closing movements that are a result of the exact linear guidance of the moving platen. The perfect interplay of these features,...

Open the catalog to page 3

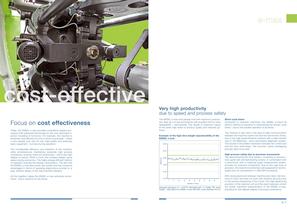

Focus on cost effectiveness Today, the ENGEL e-max provides competitive plastics pro- cessors with advanced technology for the cost-optimised in- jection moulding of tomorrow. For example, the machine is extremely cost effective not only in terms of purchase - where it wins people over with its very high-quality and extensive basic equipment - but also during operation. The considerable efficiency and precision of the machine, while simultaneously maintaining extremely high process consistancy, ensures maximum productivity - with a very high degree of uptime. What is more, the compact...

Open the catalog to page 4

Efficient energy use compact Space-saving production thanks to compact design One further advantage of all electric machines compared to hydraulic ones is their lower heat and noise emission levels. The fact that they run quietly significantly reduces the noise exposure for staff. Thanks to its compact design the machine requires very little floor space. The length-optimised clamping unit, integration of all electrical equipment in the injection unit frame, and the open injection unit are vital characteristics that help the machine achieve its compact dimensions. The open injection unit...

Open the catalog to page 5

The all electric ENGEL e-max from 500 to 1.800 kN The all electric ENGEL e-max is available in a clamp force range of between 500 and 1.800 kN. The premium quality, comprehensive basic machine is modularly expandable by adding numerous standardised technology options such as injection units with increased injection speed, or mould heating. This allows the machine to respond flexibly to individual injection moulding requirements (see page 19 for more details). Injection Units 80 / ... 200 / ... 440 / ... 740 / ...* 940 / ...* Available screw diameters in mm per injection unit Clamping units...

Open the catalog to page 6

Tried-and-trusted, precise, dependable: the ENGEL e-max injection unit Tried-and-trusted technology that you can depend on - the ENGEL e-max has the same high-performance injection units as are used for the popular, all electric ENGEL e-motion ma- chines, which have been in production use successfully for over 10 years, and continue to guarantee optimum precision. On top of this, the ENGEL e-max offers the familiar stan- dard benefits of other ENGEL injection units. They include, for example, lateral swivelling ability, which substantially faci- litates maintenance work on the injection...

Open the catalog to page 7

Fast, light and precise movements: the ENGEL e-max clamping unit Precise platen and mould movements Moving platen, modular design with uniform clamp force distribution. Precision linear bearings mean minimal coefficients of friction, and precise platen and mould guidance – even for heavy moulds. Detailed view of mould height adjustment and clamping drive Moving platen with servoelectric ejector drive Performance and precision are our focus The combination of a 5-point toggle-lever geometry and powerful servomotor drives ensures dynamic movement and shortest possible dry cycles. Just like...

Open the catalog to page 8

Optimised user ergonomics ergonomic Basic functions - Power on - User identification by means of a password - USB interfaces Settings: Clear cut control logic The control logic for the machine supports simple programming of an individual cycle sequence without special pro01 gramming skills. To support this, the cycle sequence for the injection moulding process is subdivided into separate basic sequences. These basic sequences – mould closing, injection, cooling, and mould opening – along with the additional sub-sequences are mapped to characteristic pictograms. On top of this, you can...

Open the catalog to page 9

flexible Fit for more – modularly expandable thanks to numerous standardised technology options Geared for individual requirements In addition to the premium quality and comprehensive set of standard options, the ENGEL e-max can be modified flexibly to match your individual injection moulding requirements thanks to a wide range of standardised technology options. These options include: - injection units with higher injection speed - core-pulls - EUROMAP67 - platen ejector - mould heating - mould monitoring - machine shut-off nozzles - mould shut-off nozzles - interfaces for external devices...

Open the catalog to page 10All ENGEL AUSTRIA GmbH catalogs and technical brochures

-

press | release

4 Pages

-

ENGEL services

9 Pages

-

Plasticising unit

15 Pages

-

Composite Technologies

13 Pages

-

combimelt

15 Pages

-

automotive

19 Pages

-

Amorphous Metal Moulding

5 Pages

-

smart service

11 Pages

-

smart machine

15 Pages

-

Automation

41 Pages

-

engel AUTOMATIUON

15 Pages

-

ENGEL INSERT

15 Pages

-

Trining

11 Pages

-

protect

3 Pages

-

iQ weight control

2 Pages

-

Engel Flomo

16 Pages

-

Scope of products

29 Pages

-

CC300

7 Pages

-

e-motion 30 TL

8 Pages

-

ENGEL plus

2 Pages

-

ENGEL e-cap

3 Pages

-

ENGEL e-mac

11 Pages

-

ENGEL elast

11 Pages

-

ENGEL insert PRO

7 Pages

-

ENGEL combimelt

5 Pages

-

Customized Soft-Touch

3 Pages

-

Engel EXJECTION®

4 Pages

-

ENGEL e-factory

4 Pages

Archived catalogs

-

e-motion TL

9 Pages

-

ENGEL e-victory

17 Pages

-

ENGEL e-motion

17 Pages

-

ENGEL duo

19 Pages

-

ENGEL victory

15 Pages

-

ENGEL Control

8 Pages

-

ENGEL VIPER

13 Pages

-

speed injection moulding machine

10 Pages