Catalog excerpts

Perfectly matched components and system solutions

Open the catalog to page 1

The dynamics of the market pose increasingly complex challenges to your production. ENGEL offers you solutions that precisely match your desired level of automation: from modular to tailor-made systems solutions. Automation expertise at all levels: We design and supply complete production systems in which all processes, from the injection moulding machine and the robot to the automation peripherals, are perfectly matched. You can therefore rely on the highest part quality, stable processes and maximum productivity – and that your entire production is running smoothly.

Open the catalog to page 2

Contents Automation at ENGEL. . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Added value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Ready-to-run systems solutions . . . . . . . . . . . . . . . . . . . 14 Project systems solutions. . . . . . . . . . . . . . . . . . . . . . . . 22 Robots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30 Gripper technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 Conveyor systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 Cell safety technology . . . . . . . . . . ....

Open the catalog to page 3

Your partner for efficient injection moulding applications ENGEL leads the global market for injection moulding machines. And is number 1 in the automation of entire production cells. In addition to our sales subsidiaries and our worldwide service network, more than 450 experts at ENGEL are dedicated to the development and production of modular and customised systems solutions for innovative technologies in all sectors. Our competence centres provide you with experts in applications, all certifications required and efficient overall project engineering. Comprehensive product portfolio...

Open the catalog to page 4

The unique innovations for your decisive technical advantage. As an innovative leader, our focus has always been on the continuing development of product functions and the entire line of products. We set new standards in automation technology for entire production cells with injection moulding machines. Numerous unique characteristics in mechanics, control technology and software result in faster startups, more efficient and precise processes, longer product life cycles and higher energy savings. inject 4.0 Our solutions for the smart factory Continuously increasing customer benefit has...

Open the catalog to page 5

iQ vibration control Active vibration compensation for quick and precise positioning Our ENGEL viper linear robots measure the vibrations at the end of the vertical axis close to the gripper using acceleration sensors and compensates for the vibration via the closed-loop control in the control unit and the servo drives. This innovation also compensates for vibrations of a robot mounted on a vibrating machine or touching the mould or an ejector. This results in shorter cycle times and higher process reliability during loading, part removal and depositing. event control Self-optimising cycle...

Open the catalog to page 6

integrated sequence The optimal programming experience for beginners and professionals integrated safety The integrated safety technology for flexible production cells ll individual components, as well as the system solutions of A ENGEL automation are already CE certified. This also facilitates the inspection of customised solutions. NGEL offers built-in safety for personal protection related E to heights, distances and strengths for machine and safety clearances. he integrated safety technology includes standardised electriT cal safety packages for connected or stand-alone operation of the...

Open the catalog to page 7

Ready-to-run systems solutions The modular automation solutions

Open the catalog to page 8

Ready-to-run systems solutions Separator and conveyor belts for free-falling parts without robot Simple and precise positioning under the injection moulding machines The modular automation solutions Safety gate Chutes and switches in the machine are used to distribute sprues, rejects and good parts to multiple conveyor belts. These conveyor belts are available in numerous design variants and for all machine depositing sides. Electrical outlet Belt conveyor Interface Robot Power outlet Robot or terminal block IMM options Reject/sprue selection Extension packages with safety gate, interfaces,...

Open the catalog to page 9

Pickers with discharge chutes integrated in the safety gate For part production on the most compact of footprints Durable pneumatic or dynamic servo sprue pickers are mounted on the stationary mould mounting platen. Ready-to use CE-certified solutions for discharge chutes are integrated directly into the machine guarding. Robot and conveyor belts integrated into safety gate For the most compact of injection moulding cells Expanded safety gates for small and medium-sized machines are the easiest method to allow a robot to deposit parts on a belt conveyor. Combined with tie-bar-less injection...

Open the catalog to page 10

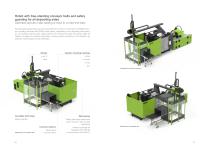

Robot with free-standing conveyor belts and safety guarding for all depositing sides Standard layouts make adding a robot to a machine easy Preconfigured standard layouts can be selected from numerous combinations of ENGEL injection moulding machines with ENGEL linear robots, depending on the depositing side (operator, non-operator, side-by-side). safety systems, the modular cell safety technology, offers full freedom of design for individual cell layouts, ensuring perfect connection to the machine, an attractive overall design and CE certification. Injection moulding machines e-motion...

Open the catalog to page 11

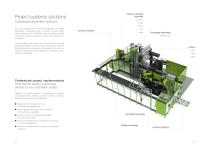

Project systems solutions Customised automation solutions

Open the catalog to page 12

Injection moulding machines If you are looking for more than a combination of modular automation components such as robots, conveyor belts, safety guarding, etc., the ENGEL team is happy to develop customised system solutions to meet your individual requirements. Our specialists have access to a comprehensive modular assembly kit system with proven process modules; they additionally develop components and features in line with your specific requirements, and integrate your preferred components and standards. Conveyor systems e-motion e-mac victory duo insert Processing technology infrared...

Open the catalog to page 13All ENGEL AUSTRIA GmbH catalogs and technical brochures

-

press | release

4 Pages

-

ENGEL services

9 Pages

-

Plasticising unit

15 Pages

-

Composite Technologies

13 Pages

-

combimelt

15 Pages

-

automotive

19 Pages

-

Amorphous Metal Moulding

5 Pages

-

smart service

11 Pages

-

smart machine

15 Pages

-

engel AUTOMATIUON

15 Pages

-

ENGEL INSERT

15 Pages

-

Trining

11 Pages

-

protect

3 Pages

-

iQ weight control

2 Pages

-

Engel Flomo

16 Pages

-

Scope of products

29 Pages

-

CC300

7 Pages

-

e-motion 30 TL

8 Pages

-

ENGEL plus

2 Pages

-

ENGEL e-cap

3 Pages

-

ENGEL e-mac

11 Pages

-

ENGEL elast

11 Pages

-

ENGEL insert PRO

7 Pages

-

ENGEL combimelt

5 Pages

-

Customized Soft-Touch

3 Pages

-

Engel EXJECTION®

4 Pages

-

ENGEL e-factory

4 Pages

Archived catalogs

-

e-motion TL

9 Pages

-

ENGEL e-victory

17 Pages

-

ENGEL e-motion

17 Pages

-

ENGEL duo

19 Pages

-

ENGEL victory

15 Pages

-

ENGEL Control

8 Pages

-

ENGEL VIPER

13 Pages

-

speed injection moulding machine

10 Pages