Catalog excerpts

VA 500/ 520 Flow sensors for compressed air and gases

Open the catalog to page 1

With and without flange Intelligent solutions for accurate flow measurement for compressed air and gases The new affordable flow sensors VA520 work according to the approved calorimetric measuring principle. An additonal pressure and temperature compenstation is not necessary. Contrary to the previously used bridge circuit the newly developed evaluation electronics records all measured values digitally. This enables very precise and fast measurements. Due to the new evaluation electronics all VA520 have an integrated Modbus output as a standard. So all parameters can be transferred via...

Open the catalog to page 2

In case of compressed air meters with integrated measuring section the ..measuring device" cannot be removed. For this reason an expensive bypass line is necessary. The design of VA 520 enables the removal and cleaning of the ..measuring device" with e.g. soap water without any dismounting of the measuring section. A closing cap grants a continuous use of the line for the duration of the cleaning. A bypass line is not necessary. The alignment pin grants an accurate installation ofthe measuring device. In most cases the compressed air is not free from oil, condensate, dirt and particles....

Open the catalog to page 3

Measuring device removable: Dismounting of the whole measuring section is not necessary, no bypass required Screw-in thread: High measuring accuracy due to defined Easy installation into the existing pipe- measuring section (inlet and outlet section) line due to integrated measuring section (suitable for 1/4", 1/2", 3/4", 1“, 1 1/4", 1 1/2“ or 2“ lines) • Easy and affordable installation Units freely selectable via keys at the display m3/h, m3/min, l/min, I/s, kg/h, kg/min, kg/s, cfm Compressed air counter up to 1.999.999.999 m3. Resetable to „zero“ via keypad Analogue output 4...20 mA,...

Open the catalog to page 4

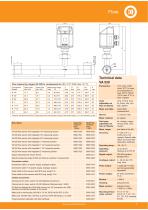

Flow measuring ranges VA 520 for compressed air (ISO 1217:1000 mbar, 20 °C) VA 520 Units adjustable via keys at display: Meas. principle: Sensor: Meas. medium: m3/h, l/min (1000 mbar, 20°C) in case of compressed air resp. Nm3/h, Nl/min (1013 mbar, 0°C) in case of gases m3/h, m3/min, l/min, I/s, ft/min, cfm, m/s, kg/h, kg/min calorimetric measurement 2 x silicium chip air, gases Gas types adjustable via keys at display: Meas. range: Accuracy: Operating temp.: Operating pressure: Digital output: Analogue output: Pulse output: Power supply: Burden: Housing: Meas. section: Mounting thread meas....

Open the catalog to page 5

High measuring accuracy due to defined measuring section (inlet and outlet section) Easy installation into the existing pipeline due to integrated measuring section and weld neck flange (according to EN 1092-1 PN 40) • Easy and affordable installation Units freely selectable via keys at the display m3/h, m3/min, l/min, I/s, kg/h, kg/min, kg/s, cfm Compressed air counter up to 1.999.999.999 m3. Resetable to „zero“ via keypad Analogue output 4...20 mA, pulse output (galvanically separated) High measuring accuracy also in the lower measuring range (ideal for leakage measurement) Negligibly...

Open the catalog to page 6

Technical data VA 520 Parameters: Flow measuring ranges VA (ISO 1217:1000 mbar, 20 °C Units adjustable via keys at display: Meas. principle: Sensor: Meas. medium: Gas types adjustable via keys at display: Meas. range: Accuracy: Operating temp.: Operating press.: Digital output: Analogue output: Pulse output: Power supply: Burden: Housing: Meas. section: Flanges: m3/h, l/min (1000 mbar, 20°C) in case of compressed air resp. Nm3/h, Nl/min (1013 mbar, 0°C) in case of gases m3/h, m3/min, l/min, I/s, ft/min, cfm, m/s, kg/h, kg/min calorimetric measurement 2 x silicium chip air, gases air,...

Open the catalog to page 7

What are the advantages of the flow measuring technology of CS Instruments ? 1) Even under pressure, the flow sensor VA 500 is mounted by means ofa standard 1/2“ ball valve. During mounting and dismounting the safety ring avoids an uncontrolled ejection of the probe which may be caused by the operating pressure. For the mounting into different pipe diameters VA 500 is available in the following probe lengths: 120, 160, 220, 300, 400 mm. So the flow sensors are being mounted into existing pipelines with inner diameters of 1/2“ upwards. The exact positioning of the sensor in the middle of the...

Open the catalog to page 8

VA 500 - Flow sensor for compressed air and gases The new VA 500 for flow measurement of compressed air and gases, optionally with display for flow in m3/h and total flow in m3. Contrary to the previously used bridge circuit the newly developed evaluation electronics records all measured values digitally. This leads to a better accuracy also in case of large measuring spans of 1:1000. Inner diameter adjustable via keypad Special features: • RS 485 interface, Modbus-RTU as a standard • Integrated display for m3/h and m3 • Usable from 1/2“ to 12“ (DN 300) • Easy installation under pressure •...

Open the catalog to page 9

400 Flow station for compressed air Chart recorder DS 400 • 3.5“ graphic display with touch screen -showsthe progression ofthe measured values in graphic form • 2 sensor inputs for flow sensors/ dew point sensors • USB interface for reading out the data logger via USB stick • 2 additional sensor inputs for pressure sensors, current meters and so on Flow measuring ranges VA 500 for compressed air (ISO 1217:1000 mbar, 20 °C) • Option: Data loggerfor 100 million measured values (2 GB SD card) • Option: Ethernet and RS 485 interface (Modbus protocol) • Option: Webserver • Option: CS Soft Basic...

Open the catalog to page 10

Configuration of flow sensor The flow sensor VA 400 can be adjusted to the respective inner diameter of the pipe in the menu of DS 400. Furthermore, the unit, the gas type as well as the reference conditions can be entered. The counter can be set to „zero“ if required. Graphic view In the graphic view all measured values are indicated as curves. It is possible to browse back on the time axis by a slide of the finger (without data logger maximum 24 h, with data logger back to the start ofthe measurement). Data logger Measured values are stored in DS 400 by means ofthe option ..integrated...

Open the catalog to page 11All ENE SYSTEM catalogs and technical brochures

-

Yusoo 8-200

21 Pages

-

ESP-25 50 100 200 300

25 Pages

-

Drain Master

51 Pages

-

VA 550/570

12 Pages

-

YUSOO BREAKER TECHNICAL DATA

15 Pages

-

DM-50 PLUS TECHNICAL DATA

3 Pages

-

DM-5S PLUS TECHNICAL DATA

3 Pages

-

DM-5N PLUS TECHNICAL DATA

3 Pages

-

YUSOO BREAKER

12 Pages

-

ENVISOL

18 Pages

-

2017 Catalogue

28 Pages

Archived catalogs

-

DRAINMASTER B

4 Pages

-

DRAINMASTER S

6 Pages