Catalog excerpts

Technical Information Condumax CLS16 and CLS16D Hygienic conductivity sensor, analog or digital with Memosens technology, cell constant k = 0.1 cm-1 Your benefits Measurement in pure and ultrapure water: • Monitoring ion exchangers • Reverse osmosis • Distillation • Electro-deionizing • WFI (Water for Injection) in the pharmaceutical industry • High measuring accuracy as cell constant is individually measured • Hygienic process connections for installation in pipes or flow chambers • Plug-in head (IP 68) / fixed cable (IP 67) • Easy to clean thanks to electro-polished measuring surfaces • Can be sterilized up to 150 ˚C (302 ˚F) • Stainless steel 1.4435 (AISI 316L), meets the highest demands of the pharmaceutical industry • Quality certificate stating the individual cell constant • Certified according to EHEDG Document 8 • Available with biological reactivity test certificate according to USP (United States Pharmacopeia) Part 87 and 88 Class VI • Available with inspection certificate according to EN 10204-3.1 The cell constant k of the sensor is 0.1 cm-1. The measuring range reaches from 0.04 to 500 μS/cm. Sensors with integrated temperature sensors are used with transmitters with automatic temperature compensation: • Liquiline CM442 / CM444 / CM448 (CLS16D only) • Liquiline CM42 • Liquiline CM14 (CLS16D only) • Mycom CLM153 • Liquisys CLM223/253 For measurement of resistivity, MΩ · cm measuring ranges are available in the menus of these transmitters. Further benefits offered by Memosens technology • Maximum process safety through contactless inductive signal transmission • Data safety through digital data transmission • Easy handling thanks to storage of sensor-specific data in the sensor • Predictive maintenance possible thanks

Open the catalog to page 1

Function and system design Measuring principle Conductive measurement of conductivity AC The conductivity of liquids is measured with the following measurement setup: Two electrodes are immersed in the medium. An AC voltage is applied to these electrodes which generates a current in the medium. The electric resistance or its reciprocal value, the conductance G, is calculated according to Ohm’s law. The specific conductivity κ is determined using the cell constant k that is dependent on the sensor geometry. Conductive measurement of conductivity AC I U Power supply Current meter Voltage...

Open the catalog to page 2

Reliability The Memosens technology digitalizes the measured values in the sensor and transfers them to the transmitter contactlessly and free from interference potential. The result: • An automatic error message is generated if the sensor fails or the connection between sensor and transmitter is interrupted. • The availability of the measuring point is dramatically increased by immediate error detection. Maintainability Sensors with Memosens technology have integrated electronics that allow for saving calibration data and further information such as total hours of operation and operating...

Open the catalog to page 3

Input Measured variable • Conductivity • Temperature Measuring range Conductivity (referenced to water at 25 ˚C (77 ˚F)) CLS16D and CLS16 0.04 to 500 μS/cm valid in the specified temperature range specified measuring accuracy up to 100 ˚C (212 ˚F) Temperature CLS16D -5 to 100 ˚C (23 to 212 ˚F) CLS16 -5 to 150 ˚C (23 to 300 ˚F) specified measuring accuracy up to 100 ˚C (212 ˚F) Cell constant Temperature compensation Power supply Electrical connection CLS16 The sensor is connected via the CPK9 measuring cable. For the wiring diagram, refer to the Operating Instructions of the transmitter...

Open the catalog to page 4

Performance characteristics, in general Measured error Each individual sensor is factory-measured in a solution of approx. 5 μS/cm with a reference system traceable to NIST or DKD. The exact cell constant is entered into the supplied quality certificate. The maximum measured error in cell constant determination is 1.0 %. Performance characteristics, CLS16D only Conductivity response time Temperature response time Maximum measured error 2 % of the measured value up to 200 μS/cm 3 % of the measured value from 200 to 500 μS/cm 0.2 % of the measured value + 3 nS/cm Installation Installation...

Open the catalog to page 5

Environment Ambient temperature Storage temperature Protection degree CLS16 Fixed cable version TOP68 plug system CLS16D IP 67 / NEMA 6 IP 68 / NEMA 6 IP 68 / NEMA Type 6P (10 m water column, 25 ˚C, 168 h) Process Process temperature Normal operation: Sterilization (max. 45 min): The maximum temperature for communication between Memosens sensors and the transmitter is 130 ˚C (266 ˚F). Process pressure Pressure/temperature load curves Mechanical pressure-temperature stability of A

Open the catalog to page 6

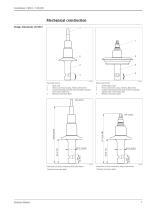

Mechanical construction Design, dimensions of CLS16 Fixed cable version Plug-in head version Fixed cable Process connection (clamp, Varivent, BioControl) Coaxial measuring electrode, electro-polished, stainless steel 1.4435 (AISI 316L) Minimum immersion depth TOP68 plug-in head Process connection (clamp, Varivent, BioControl) Coaxial measuring electrode made of electro-polished, stainless steel 1.4435 (AISI 316L) Minimum immersion depth Dimensions of clamp connection, fixed-cable version *minimum immersion depth Dimensions of clamp connection, plug-in head version *minimum immersion depth

Open the catalog to page 7

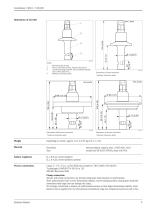

Dimensions o/BioControl connection, fixed-cable version *minimum immersion depth Dimensions o/BioControl connection, plug-in head *minimum immersion depth Dimensions of Varivent connection, fixed-cable version *minimum immersion depth Dimensions of Varivent connection, plug-in head version *minimum immersion depth

Open the catalog to page 8

Memosens plug-in head Process connection (clamp, Varivent, BioControl) Coaxial measuring electrode, electro-polished stainless steel 1.4435 (AISI 316 L) Minimum immersion depth Dimensions of clamp connection *minimum immersion depth Dimensions of BioControl connection Dimensions of Varivent connection *minimum immersion depth *minimum immersion depth Depending on version, approx. 0.13 to 0.75 kg (0.3 to 1.7 lb.) Electrodes: Seal: Surface roughness Ra ≤ 0.8 μm, electro-polished Ra ≤ 0.4 μm, electro-polished, optional Process connections Clamp 1", 1½", 2" acc. to ISO 2852 (also suitable for...

Open the catalog to page 9All Endress+Hauser AG catalogs and technical brochures

-

FTL41

3 Pages

-

FTL51B

6 Pages

-

FMG50

10 Pages

-

PTP31B

3 Pages

-

Proline Promass E 300

13 Pages

-

CUS71D

3 Pages

-

iTEMP TMT162

3 Pages

-

CLS54D

3 Pages

-

CLS50D

3 Pages

-

FMX21

5 Pages

-

Liquipoint FTW23

3 Pages

-

Deltapilot FMB50

7 Pages

-

iTHERM TM401

3 Pages

-

COS61D

3 Pages

-

Proline Promag 10W

4 Pages

-

Proline Promag 10P

4 Pages

-

Liquiphant FTL51

6 Pages

-

FMD72

5 Pages

-

PMP51

7 Pages

-

Cerabar PMC51

7 Pages

-

Cerabar PMP75

8 Pages

-

Proline t-mass B 150

4 Pages

-

Proline Prosonic Flow 93P

5 Pages

-

Proline Prosonic Flow 92F

4 Pages

-

FMD78

8 Pages

-

PMD75

10 Pages

-

FMI51

4 Pages

-

FMU30

7 Pages

-

FMP57

4 Pages

-

FMP55

4 Pages

-

FMP54

5 Pages

-

FMP51

5 Pages

-

FMP50

4 Pages

-

FMR52

4 Pages

-

FMR51

5 Pages

-

F 200

13 Pages

-

D 200

12 Pages

-

E 100

5 Pages

-

C 200

11 Pages

-

Tophit CPS471 and CPS471D

20 Pages

-

Tophit CPS491 and CPS491D

20 Pages

-

B_unit4_1

1 Pages

-

B_unit3_3

1 Pages

-

B_unit3_2

1 Pages

-

Wort cooler

1 Pages

-

Condumax CLS16D/CLS16

16 Pages

-

Competence in Oil and Gas

30 Pages

-

Pressure Transducer CT40

24 Pages

-

Liquiphant T FTL20

20 Pages

-

Gammapilot M FMG60

48 Pages

-

Deltabar S PMD70

96 Pages

-

Deltapilot S FMB70

56 Pages

-

Liquicap T FMI21

40 Pages

-

Prosonic S FDU91

40 Pages

-

Levelflex M FMP40

72 Pages

-

Micropilot FMR50

76 Pages

Archived catalogs

-

System components

20 Pages

-

Flow Measurement

32 Pages