Website:

EMCO GmbH

Website:

EMCO GmbH

Group: Emco

Catalog excerpts

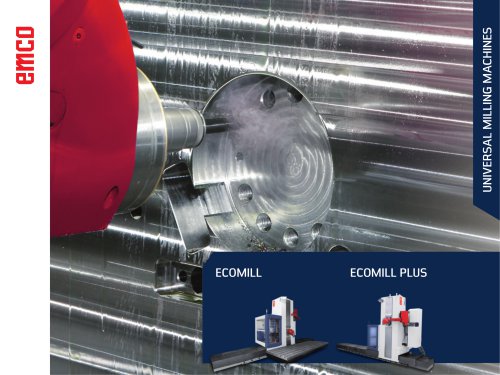

EMCOMILL SERIES

Open the catalog to page 1

TOOL MAGAZINE The flexible, vertical CNC milling machines for 3-axis milling operations have a compact machines layout, a travel of 1 800 / 1 200 or 750 mm in the X-axis, 610 mm in the Y-axis, the latest control technology, as well as a very attractive price-performance ratio. The solid fixed table and large work area enable the machining of heavy workpieces weighing up to 2 000 kg. / Large machine doors / Optimum view into the work area / Protected, elevated guide systems / Fixed table for high workpiece weights MACHINE BASE / Machine bed made of a special ribbed welded steel construction...

Open the catalog to page 2

HIGHLIGHTS / High-performance milling spindles / Flexible tool system / Large work area with wide machine doors The EMCOMILL series is equipped with state-of-the-art control technology, either Siemens 828D with ShopMill, Heidenhain TNC 620 or Fanuc 0i-MF with Manual Guide i (Fanuc: EMCOMILL 1200 / 750) are available. The control panel includes a swivel function for an ergonomic working position. / Solid fixed table for workpiece weights up to 2 000 kg / State-of-the-art control technology from Siemens, Heidenhain, Fanuc (Fanuc: EMCOMILL 1200 and 750) MACHINING TABLE The new EMCOMILL series...

Open the catalog to page 3

/ Tool magazine with 40 or 60 stations / Tool holder ISO 40 / BT 40 / HSK-A63 / NC-rotary table / Glass scales in all axes P [kW] / Alarm status lamp / Control cabinet cooling unit / Automatic tool measuring / Coolant and air through the spindle SIDE TOOL MAGAZINE DOOR GLASS SCALES IN X, Y, Z AXES The side tool magazine door allows fast loading and unloading, as well as control and cleaning of the tools. Glass scales are used for measuring linear position, eliminating thermal deviations and increasing machine accuracy. The pressurisation prevents the scales‘ contamination. ROTARY TABLE...

Open the catalog to page 4

WORK AREA INSTALLATION PLAN

Open the catalog to page 5

WORK AREA INSTALLATION PLAN

Open the catalog to page 6

WORK AREA INSTALLATION PLAN

Open the catalog to page 7

Work area Travel in X-axis Tool magazine Number of tool stations Tool change time (tool / tool) Min./max. spindle nose-table distance (mechanical spindle) Max. tool diameter (with empty station) Min./max. spindle nose-table distance (motor spindle) Table Axes Table dimensions length / width T-grooves: number, width, spacing Rapid motion speed in X, Y, Z Distance table surface / floor Speed range Power supply Overall height Main spindle (direct drive) General data Spindle motor power (S6) Installation area W × D (without chip conveyor, with tank) Total weight of the machine Direct drive...

Open the catalog to page 8

EMCO GmbH / Salzburger Str. 80 / 5400 Hallein-Taxach / Austria / T +43 6245891-0 / F +43 624586965 / info@emco.at EN9083 . 03/23 . Modifications reserved. We cannot accept any liability for printing errors beyond standard

Open the catalog to page 9All EMCO GmbH catalogs and technical brochures

-

Turn Mill Assist

3 Pages

-

FlexLoader

3 Pages

-

Fyler Product overview

8 Pages

-

INDUSTRIAL TRAINING

25 Pages

-

CNC Lathe MAXXTURN 45

10 Pages

-

HYPERTURN 65 PM HP

9 Pages

-

Universal Machining Centre

9 Pages

-

CNC Lathe Maxxturn 25

9 Pages

-

CNC Lathe Maxxturn 45

10 Pages

-

EMCO Vertical Turning Machines

15 Pages

-

EMCOMAT E-200 MC

6 Pages

-

CNC Lathe S45

3 Pages

-

CNC Lathe S65

3 Pages

-

MEDICAL TECHNOLOGY

14 Pages

-

Turning Center EMCOTURN E25

8 Pages

-

CNC Lathe EMCOTURN E45

12 Pages

-

Emcoturn E65

13 Pages