Website:

EMCO GmbH

Website:

EMCO GmbH

Group: Emco

Catalog excerpts

MAXXTURN 25 Universal turning center for the complete machining of small, precision parts

Open the catalog to page 1

BIG PERFORMANCE FOR SMALL PARTS The EMCO MAXXTURN 25. The perfect solution for the complete machining of small parts. Comapct, economical and high precision. Suitable for bar parts up to a diameter of 25 mm and chucked parts up to 0 85 mm. Fitted with a counter spindle, Y axis and driven tools. The tool turret has space for 12 VDI16 tool holders. The 36 indexing positions mean the number of tools can be increased to 42 cutting edges. The MAXXTURN 25 comes with a Siemens or Fanuc control including ShopTurn or ManualGuide conversational programming system. i WORK AREA / Spacious / Free chip...

Open the catalog to page 2

Designed on the basis of FEM analyses, the MAXXTURN 25 meets the high demands of modern machining in an ideal manner. Maintenance-free roller guides in all linear axes ensure high stability and precision. Another advantage is offered by minimum lubricant consumption teamed with long tool lives. When it comes to shaft processing, the machine can be equipped with tailstock or counter-spindle. The counter-spindle offers the advantage of being able to finish the workpiece completely on all sides. This also includes drilling and milling operations on the rear side. / 12 position VDI 16 turret...

Open the catalog to page 3

Technical Highlights Main spindle Counter spindle Being mounted on pre-stressed high-precision bearings, the main spindle can reach speeds ranging from 0–8000 rpm, making the production of small parts extremely economical and exact. The MAXXTURN 25 has a hydraulically operated hollow clamping cylinder with 25.4 mm bar clearance as standard equipment. A C axis with holding brake is also a standard fitting for milling operations. Resolution: 0.001°. The MAXXTURN 25 MY is also available in a tailstock version. The tailstock is set up on the linear roller slide and can be automatically...

Open the catalog to page 4

The EMCO short bar loaders. Universal and powerful. Short and to the point. The EMCO SL1200 is the perfect solution for automatic feeding and loading of cut-to-length bars. The key advantages are a small footprint and rapid loading times resulting from shorter strokes. for service purposes. Besides, it can comfortably be incorporated into the production process using the machine control‘s programme input masks. Minimum setup efforts are required when switching over to other bar diameters. The technology. The SL1200 can be used immediately as a “plug-and-play” solution. Their extremely small...

Open the catalog to page 5

Tool Holders For the complete processing of small complex components, a large number of stationary and driven tool holders are available. By using multiple tool holders, the number of tools on the turret can be increased considerably. Finished part conveyor The finished-part pick-up device puts the parts on an accumulating conveyor. A discontinuous belt ensures that the often very complex parts do not fall onto each other. HOLDING BRAKE AT THE MAIN SPINDLE For drilling and milling operations, the respective spindle is always positioned via the C axis. In addition, the main spindle can be...

Open the catalog to page 6

Maxxturn 25 with SL1200 1 and Chip Conveyor Maxxturn 25 with counter spindle 1

Open the catalog to page 7

WORK AREA rMaxxturn 25 with tailstock Work area Technical dataTool turret Swing over bed 0 325 mm Turret indexing time Travel Driven tools MAXXTURN25 Travel in in Z2 350 mm Number of driven tools 6 Main spindle Feed drives Rapid motion speed X / Y / Z 20 / 10 / 30 m/min Feed force in the X / Y / Z axis 3000 / 4000 / 4000 N Coolant system Counter spindle Speed range 0 - 8000 rpm Rapid motion speed 1000 rpm Power consumption Connected load 12 kVA Dimensions and weight Height of spindle center above floor 1140 mm Total machine height 1870 mm Foot print (without chip conveyor) LxD 2180 x 1425...

Open the catalog to page 8

EMCO GmbH / Salzburger Str. 80 / 5400 Hallein-Taxach / Austria / T +43 6245891-0 / F +43 624586965 / info@emco.at www.emco-world.com EN4580 . 02/20 . Subject to change due technical progress. Errors and omissions excepted. beyond standard

Open the catalog to page 9All EMCO GmbH catalogs and technical brochures

-

Turn Mill Assist

3 Pages

-

FlexLoader

3 Pages

-

Fyler Product overview

8 Pages

-

INDUSTRIAL TRAINING

25 Pages

-

CNC Lathe MAXXTURN 45

10 Pages

-

HYPERTURN 65 PM HP

9 Pages

-

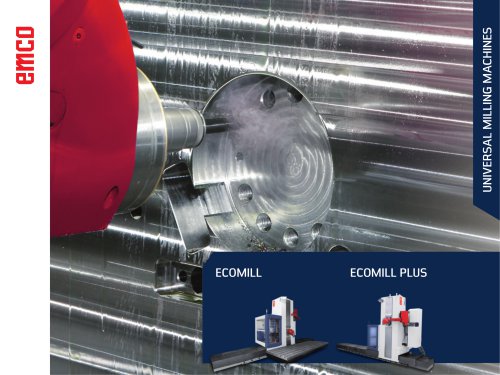

Universal Machining Centre

9 Pages

-

CNC Lathe Maxxturn 25

9 Pages

-

CNC Lathe Maxxturn 45

10 Pages

-

EMCO Vertical Turning Machines

15 Pages

-

EMCOMAT E-200 MC

6 Pages

-

CNC Lathe S45

3 Pages

-

CNC Lathe S65

3 Pages

-

MEDICAL TECHNOLOGY

14 Pages

-

Turning Center EMCOTURN E25

8 Pages

-

CNC Lathe EMCOTURN E45

12 Pages

-

Emcoturn E65

13 Pages