Website:

EMCO GmbH

Website:

EMCO GmbH

Group: Emco

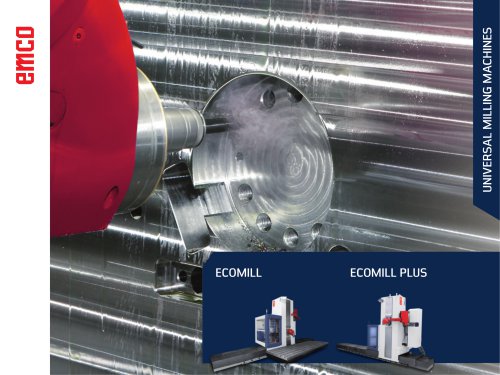

Catalog excerpts

UMILL 630 Universal machining center for 5-axis machining

Open the catalog to page 1

Equipped with a front table support, the UMILL 630 - our universal and vertical CNC machining center - is capable of milling parts featuring an edge size of 445 x 445 x 400 mm and a weight of up to 200 kg using highly precise and highly efficient, simultaneous 5-axis machining. Its compact design in cast iron and welded steel, optimised by FEM analysis, with direct drives in X-Y-Z and standard linear scales among its features, it guarantees the maximum in rigidity and thermosymmetry, the highest precision and an excellent surface quality of the workpiece. With its important technological...

Open the catalog to page 2

TECHNICAL HIGHLIGHTS TOOL CHANGER SWIVEL-ROTARY TABLE TRAVEL RANGE The tool changer of the Umill 630 is a drum magazine for 30 tools. A tool magazine with 60/90 tool stations is available as option. The tools are managed according to the variable tool station coding principle (random), which means that tools are always deposited in the first free magazine station for time reasons. Other tool changer stations are available upon request. The swivel-rotary table has a large clamping area of 630 x 500 mm and can bear loads of up to 300 kg thanks to the front table support. This makes it...

Open the catalog to page 3

Standard Apps NETWORKS ARE CREATED INDIVIDUALLY OUR SOLUTIONS AS WELL Staying in touch is important not only among human beings. Persons, machines and the whole production environment must also be connected perfectly and safely in order to ensure efficient procedures during the production process. With EMCONNECT, the machine is optimally equipped for this purpose. The optional EMCONNECT Digital Services offer innovative online services for optimized machine operation. The user has always the control of the machine status. The automatic notification in case of malfunctions or standstill of...

Open the catalog to page 4

INSTALLATION PLAN Machine with optional equipment INSTALLATION PLAN

Open the catalog to page 5

WORK AREA TECHNICAL DATA Travel and tolerances Tool magazine Number of tool stations Tool changing type Tool management Distance spindle nose - table (min. - max. / motor spindle) Tool changing time (tool-tool) according to VDI 2852 Swivel range B-axis Range of rotation C-axis (rotary table) Max. tool diameter (without neighbouring tools) Positioning accuracy P according to VDI 3441 * Positioning repeatability Ps according to VDI 3441 * Positioning accuracy B-axis (tilting) Total tool weight supported by the magazine Positioning accuracy C-axis (table) Coolant tank Feed Tank capacity Rapid...

Open the catalog to page 6

EMCO GmbH / Salzburger Str. 80 / 5400 Hallein-Taxach / Austria / T +43 6245 891-0 / F +43 6245 86965 / info@emco.at www.emco-world.com EN9039 . 03/23 . Technical modifications reserved. Errors and omissions excepted. beyond standard

Open the catalog to page 7All EMCO GmbH catalogs and technical brochures

-

Turn Mill Assist

3 Pages

-

FlexLoader

3 Pages

-

Fyler Product overview

8 Pages

-

INDUSTRIAL TRAINING

25 Pages

-

CNC Lathe MAXXTURN 45

10 Pages

-

HYPERTURN 65 PM HP

9 Pages

-

Universal Machining Centre

9 Pages

-

CNC Lathe Maxxturn 25

9 Pages

-

CNC Lathe Maxxturn 45

10 Pages

-

EMCO Vertical Turning Machines

15 Pages

-

EMCOMAT E-200 MC

6 Pages

-

CNC Lathe S45

3 Pages

-

CNC Lathe S65

3 Pages

-

MEDICAL TECHNOLOGY

14 Pages

-

Turning Center EMCOTURN E25

8 Pages

-

CNC Lathe EMCOTURN E45

12 Pages

-

Emcoturn E65

13 Pages