Website:

EMCO GmbH

Website:

EMCO GmbH

Group: Emco

Catalog excerpts

MAXXTURN 95 Universal CNC turning center for machining shafts and chuck parts

Open the catalog to page 1

Maxxturn 95 is suitable for part lengths of up to 1300 mm and a turning diameter of 500 mm and can handle turning and milling operations involving heavy machining as perfectly as machining of precision parts with highest surface quality. A highly accurate C-axis, a rigid Y-axis with large movement path and high rapid traverses complete the performance package. CONTROL UNIT / Ergonomic, swivel-type control panel / Sinumerik 840D sl with 15“ color monitor / Comprehensive machining cycles / 3D simulation / USB interface, 230V power socket / Travel +80 / -60 mm / 90° implemented in the machine...

Open the catalog to page 2

Designed on the basis of FEM analyses, the MAXXTURN 95 meets the high demands of modern machining in an ideal manner. The machine‘s core element is the one-piece machine bed. It is designed as a closed welded steel construction and filled with HYDROPOL®. Additional reinforcements ensure maximum stability in the more highly stressed areas. This guarantees maximum stiffness, precision and optimum vibration damping. The MAXXTURN 95 stands for high durability teamed with high processing accuracy. It is the basis for production with a high added value. MAIN SPINDLE - Belt-drive Dati tecnici 750...

Open the catalog to page 3

HIGHLIGHTS / xtremly robust construction E / op machining precision T / igh rapid motion speed H / table Y-axis with large travel S / ptional: NC steady rest or tailstock O / tate-of-the-art control technology S / riven tools with C-axis D / imple, conversational programming S BMT TURRET For cost-effective production of complex turning/milling work pieces, in which milling is predominant, the optional BMT 55P turret with water-cooled direct drive is available. With a maximum of 12000 rpm, 30 Nm and 10 kW, this turret offers optimum conditions, stability for complete machining and maximum...

Open the catalog to page 4

NETWORKS ARE CREATED INDIVIDUALLY. OUR SOLUTIONS AS WELL. Staying in touch is important not only among human beings. Persons, machines and the whole production environment must also be connected perfectly and safely in order to ensure efficient procedures during the production process. With EMCONNECT, the machine is optimally equipped for this purpose. The optional EMCONNECT Digital Services offer innovative online services for optimized machine operation. The user has always the control of the machine status. The automatic notification in case of malfunctions or standstill of the machine...

Open the catalog to page 5

THE EMCO GANTRY LOADER. INDIVIDUAL PROCESS OPTIMIZATION. Workpiece magazine Blank-specific pallet attachments enable oriented loading of blanks into the machine and increase the parts stock for unmanned production. Changeover times are reduced or eliminated thanks to the perfect adjustment to the customer‘s parts. GANTRY LOADER PALLET MAGAZINE (with 20 stations) GRIPPER SYSTEM 2 x 3-jaw double gripper head 4-station pallet attachment for tees 6-station pallet attachment for articulated brackets Multi-pallet attachment for a family of parts ADVANTAGES / Fully automatic loading and unloading...

Open the catalog to page 6

MACHINE LAYOUT Maxxturn 95 Maxxturn 95 with gantry loader 5545 MACHINE LAYOUT

Open the catalog to page 7

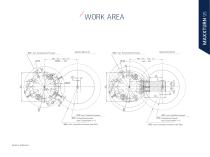

WORK AREA TECHNICAL DATA Work area GANTRY LOADER Feed drive Tailstock with quill Tailstock travel Rapid motion speed X / Z / Y Swing over cross silde Feed force in the X axis Distance between centers Feed force in the Z axis Traverse speed horizontal Tool holding shaft (with integrated bearings) Feed force in the Y axis Traverse speed vertical Acceleration time from 0 to rapid motion Draw tube bore Application example: Maxxturn 95 Tool turret Coolant system A number of tool positions Reitstock mit MK4-Pinole flanged / shaft parts Tool holding shaft in accordance Tank volume Pump performance...

Open the catalog to page 8

WORK AREA max. Drehdurchmesser Umlaufdurchmesser über Querschlitten Y=0 max. Umlaufdurchmesser über Bett max. Drehdurchmesser Umlaufdurchmesser über Querschlitten Y=0 max. Umlaufdurchmesser über Bet

Open the catalog to page 9

EMCO GmbH / Salzburger Str. 80 / 5400 Hallein-Taxach / Austria / T +43 6245891-0 / F +43 624586965 / info@emco.at www.emco-world.com EN4390 . 02/20 . Subject to change due to technical progress. Errors and omissions excepted. beyond standard

Open the catalog to page 10All EMCO GmbH catalogs and technical brochures

-

Turn Mill Assist

3 Pages

-

FlexLoader

3 Pages

-

Fyler Product overview

8 Pages

-

INDUSTRIAL TRAINING

25 Pages

-

CNC Lathe MAXXTURN 45

10 Pages

-

HYPERTURN 65 PM HP

9 Pages

-

Universal Machining Centre

9 Pages

-

CNC Lathe Maxxturn 25

9 Pages

-

CNC Lathe Maxxturn 45

10 Pages

-

EMCO Vertical Turning Machines

15 Pages

-

EMCOMAT E-200 MC

6 Pages

-

CNC Lathe S45

3 Pages

-

CNC Lathe S65

3 Pages

-

MEDICAL TECHNOLOGY

14 Pages

-

Turning Center EMCOTURN E25

8 Pages

-

CNC Lathe EMCOTURN E45

12 Pages

-

Emcoturn E65

13 Pages