Website:

EMCO GmbH

Website:

EMCO GmbH

Group: Emco

Catalog excerpts

MEDICAL TECHNOLOGY

Open the catalog to page 1

RELIABLE PARTNERS IN A DYNAMIC INDUSTRY The demands of medical technology on machining production technologies have developed as dynamically as the industry: it is necessary to meet the increasing complexity and individualization of products while at the same time meeting high price pressure and high safety and quality requirements. EMCO is represented with its product range of lathes and milling machines in various subsectors of medical technology. The flexibility of the machines, their multifunctional use, digitalization and automation possibilities and above all a team of process and...

Open the catalog to page 2

HIGHEST PRECISION FOR MORE QUALITY OF LIFE MEDICAL DEVICES Whether computer tomographs, laboratory automation or centrifuges, there are a large number of product groups in the field of medical technology equipment that have one thing in common: they consist of complex components and assemblies that place the highest demands on machining production. A wide variety of materials and shapes are used, and high demands are placed on surface accuracy, dimensional and shape accuracy and reproducibility. EMCO offers the right solution with its extensive product portfolio and decades of know-how....

Open the catalog to page 3

MEDICAL DEVICES The precision machining of large and complex workpieces in small to medium batch sizes is a great challenge for the flexibility of machine tools. With the HYPERTURN 100 POWERMILL large components can be completely machined in two clamping positions without intervention. With two spindles, a turning/milling spindle, a comprehensive tool magazine and much more, a wide range of machining operations can be carried out. And all this with minimum set-up effort. Turning/milling centre HYPERTURN 100 POWERMILL for the complete machining of large-volume, complex workpieces HIGHLIGHTS...

Open the catalog to page 4

PROSTHESES AND ORTHOSES High stress with low weight, high wearing comfort and high functionality - these are the core features for prostheses. In terms of design, this means complex, precise, compact components made of high-strength aluminum and in some cases titanium. With the HYPERTURN 65 POWERMILL the components can be produced either from the bar up to ø 100 mm, but also as inserts up to ø 300 mm. With two spindles, a turning/milling spindle, a tool turret and an extensive tool magazine, highly complex components can be completely machined and produced without burrs. High-performance...

Open the catalog to page 5

DENTAL Mostly, these are small, filigree but highly precise workpieces made of stainless steel, which are used in turbines, straight and contra-angle handpieces, couplings or air and electric motors. Clamping for machining represents a great challenge. A lot of know-how is necessary to be able to survive in this segment. The HYPERTURN 45 G3 with two spindles, two tool turrets including direct drive and a Y-axis, offers all the prerequisites for the economic production of these components. High flexibility in the use of a wide variety of clamping devices, coupled with sensitive differential...

Open the catalog to page 6

IMPLANTS Increasing life expectancy, risky hobbies and exaggerated competitive sports are just a few of the things that make surgeons in the operating room perform at their best. Associated with this is the use of implants, some of which are very complex and usually pose great challenges to the cutting technology during manufacture. Mostly it is components made of high-alloy steels, titanium alloys or ceramic materials that place very special demands on the machine tool. The HYPERTURN 65 TRIPLETURN with two spindles, three tool turrets including direct drive and up to three Y-axes enables...

Open the catalog to page 7

PHARMACY The components and assemblies used in mechanical and plant engineering for the production of pharmaceutical products also present special challenges. From the forging die for the tablet press made of tool steel to the piping made of stainless steel. High precision, contour accuracy, economy and high availability guarantee competitiveness in this sector. The MAXXMILL 750 with its powerful, direct-driven milling spindle, dynamic feed axes and rotary swivel table offers all the prerequisites for the economical production of complex components in one clamping. This guarantees...

Open the catalog to page 8

MEDICAL INSTRUMENTS Medical instruments represent the forestry of the senses as tools for doctors. Sensitivity, precision, handiness and sterility are basic requirements for successful interventions. Accordingly, the partly bulky, thin-walled components place high demands on the production specialist. The correct clamping, the optimum cutting sequence and collision-free complete machining require many years of experience. The UMILL 630 with its five directly driven axles including 5-axis interpolation has been specially designed for these requirements. It impresses with its compactness and...

Open the catalog to page 9

FLEXIBLE, MULTIFUNCTIONAL, EFFICIENT EMCO TURNING AND MILLING MACHINES IN MEDICAL TECHNOLOGY MAXXTURN 25 DENTAL / dental implant DENTAL / abutment carrier Mate Material Cycle time Cycle time Without chip conveyor: 2080 mm DENTAL / contra-angle handpiece DENTAL / handpiece Stainless steel Stainless steel Without chip conveyor: 2665 mm Cycle time

Open the catalog to page 10

IMPLANT / hip joint inlay IMPLANT / Hip joint head Technical ceramics Technical ceramics Cycle time Cycle time With chip conveyor: 3830 mm IMPLANT / Hip joint screw cup IMPLANT / hip joint inlay Cycle time Cycle time With chip conveyor: 4175 mm IMPLANT / Hip joint head IMPLANT / bone screw Cycle time With chip conveyor: 5300 mm

Open the catalog to page 11

PROTHESESES / Clamping sleeve PROTHESESES / head piece High- strength aluminum High- strength aluminum Cycle time With chip conveyor: 5215 mm MEDICAL DEVICES / Centrifuge beakers MEDICAL DEVICES / sensor carriers High- strength aluminum Cycle time Cycle time With chip conveyor: 5300 mm MEDICAL DEVICES / Centrifuge rotor Dimension With chip conveyor: 8882 mm MEDICAL DEVICES / matrix plates Dimension High-alloy steel Cycle time

Open the catalog to page 12

DENTAL / Dentures Dimension Cycle time Cycle time Without chip conveyor: 1600 mm IMPLANT / bone plate IMPLANT / Hip stem Dimension Cycle time Cycle time Without chip conveyor: 2770 mm IMPLANT / Femur component MEDICAL INSTRUMENTS / Dental forceps Dimension Material Cycle time Without chip conveyor: 2225 mm Cobalt Chromium steel Stainless steel Cycle time

Open the catalog to page 13All EMCO GmbH catalogs and technical brochures

-

Turn Mill Assist

3 Pages

-

FlexLoader

3 Pages

-

Fyler Product overview

8 Pages

-

INDUSTRIAL TRAINING

25 Pages

-

CNC Lathe MAXXTURN 45

10 Pages

-

HYPERTURN 65 PM HP

9 Pages

-

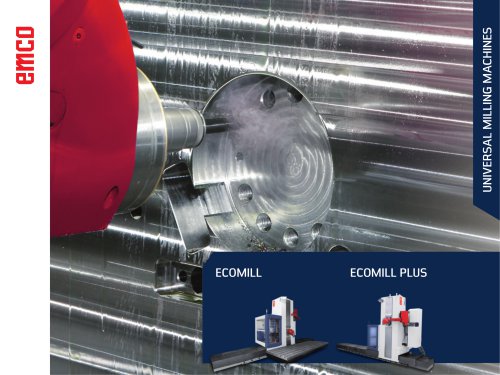

Universal Machining Centre

9 Pages

-

CNC Lathe Maxxturn 25

9 Pages

-

CNC Lathe Maxxturn 45

10 Pages

-

EMCO Vertical Turning Machines

15 Pages

-

EMCOMAT E-200 MC

6 Pages

-

CNC Lathe S45

3 Pages

-

CNC Lathe S65

3 Pages

-

Turning Center EMCOTURN E25

8 Pages

-

CNC Lathe EMCOTURN E45

12 Pages

-

Emcoturn E65

13 Pages