Website:

EMCO GmbH

Website:

EMCO GmbH

Group: Emco

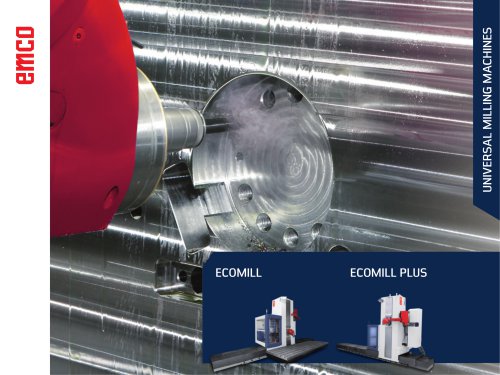

Catalog excerpts

Moving Column Machining Center Further information on the MMV series can be found here!

Open the catalog to page 1

MAXIMUM PRECISION – ALSO WITH LARGE DIMENSIONS TOOL MAGAZINE / Tool changer with 40 tools and up to 120 tools depending on the machine‘s configuration (static or moving) / Thanks to the lateral magazine door (2x in case of pendulum machining), it is possible to check and set up the tools in parallel with the machining process (only in case of static magazines) REAR MACHINE COMPARTMENT Moving Column Machining Center for 4 or 5 axes machining of big and heavy parts for small to medium lot sizes. Rapid travel up to 50 m/min with the utmost in precision. The superstructure is highly rigid, even...

Open the catalog to page 2

HIGHLIGHTS / Flexible modular construction and ergonomic, attractive design High-performance motor spindle with speed range of 50-15000 rpm, power 46 kW and max. torque 170 Nm, B- and C-axis with torque motors and encoders, linear scales in X-, Y-, Z-axis as standard. The features that make the machines of the MMV series the ideal machining centres for high quality milling performance and allow the complete production of complex workpieces with excellent surface quality. For large tools and higher cutting performance, an optional motor spindle with HSK-A100 with 10000 rpm and max. torque...

Open the catalog to page 3

OPTIONS /Workpiece and tool measurement / Coolant through the spindle / Automatic doors / Hydraulic device for clamping systems / Second integrated rotary table for 5 axes machining in pendulum operation / Thermal compensation of the milling spindle MILLING SPINDLE The B-axis is driven by a highly dynamic torque motor, therefore achieving a wide pivoting range of +/- 120 degrees. The Y-axis has a ram configuration. This design uses long way guides in order to attain the required rigidity. Its high precision is guaranteed by the motor installed with a rigid coupling directly on the screw....

Open the catalog to page 4

Standard Apps NETWORKS ARE CREATED INDIVIDUALLY OUR SOLUTIONS AS WELL Staying in touch is important not only among human beings. Persons, machines and the whole production environment must also be connected perfectly and safely in order to ensure efficient procedures during the production process. With EMCONNECT, the machine is optimally equipped for this purpose. The optional EMCONNECT Digital Services offer innovative online services for optimized machine operation. The user has always the control of the machine status. The automatic notification in case of malfunctions or standstill of...

Open the catalog to page 5

WORKING AREA MMV 3200 HSK A100 WITH PENDULUM MODE WORKING AREA MMV 3200 ISO 40 / HSK A63 WITH PENDULUM MODE

Open the catalog to page 9

WORKING AREA MMV 4200-6200 HSK A100 WITH PENDULUM MODE WORKING AREA MMV 4200-6200 ISO 40 / HSK A63 WITH PENDULUM MODE

Open the catalog to page 10

TECHNICAL DATA Min. - max. distance spindle nose - table (horizontal) HSK-A100 Min. - max. distance spindle nose - table (vertical) HSK-A100 Min. - max. distance spindle nose - table (horizontal) ISO 40 / BT 40 / HSK-A63 Min. - max. distance spindle nose - table (vertical) ISO 40 / BT 40 / HSK-A63 Feed drives X / Y / Z rapid motion speeds Slot size Slot spacing Maximum table load (equally distributed) Rotary table Diameter Maximum table load Torque motor Torque motor Torque motor Torque motor Main spindle ISO / BT Speed range Spindle power Tool taper DIN 69871 / optional

Open the catalog to page 11

TECHNICAL DATA Main spindle HSK-A63 HSK A63 (optional) Tool magazine (stationary) HSK-A100 Speed range Number of tool stations (options) Option with tool magazine left/right Changeover principle Spindle power Tool taper Main spindle HSK-A100 (optional) Speed range Spindle power Max. tool diameter (without adjacent tools) Max. tool magazine weight Automatic central lubrication with grease Automatic central lubrication with grease Automatic central lubrication with grease Automatic central lubrication with grease Automatic central lubrication with grease Automatic central lubrication with...

Open the catalog to page 12

EMCO GmbH / Salzburger Str. 80 / 5400 Hallein-Taxach / Austria / T +43 6245 891-0 / F +43 6245 86965 / info@emco.at www.emco-world.com EN9078 . 03/23 . Technical modifications reserved. Errors and omissions excepted. beyond standard

Open the catalog to page 13All EMCO GmbH catalogs and technical brochures

-

Turn Mill Assist

3 Pages

-

FlexLoader

3 Pages

-

Fyler Product overview

8 Pages

-

INDUSTRIAL TRAINING

25 Pages

-

CNC Lathe MAXXTURN 45

10 Pages

-

HYPERTURN 65 PM HP

9 Pages

-

Universal Machining Centre

9 Pages

-

CNC Lathe Maxxturn 25

9 Pages

-

CNC Lathe Maxxturn 45

10 Pages

-

EMCO Vertical Turning Machines

15 Pages

-

EMCOMAT E-200 MC

6 Pages

-

CNC Lathe S45

3 Pages

-

CNC Lathe S65

3 Pages

-

MEDICAL TECHNOLOGY

14 Pages

-

Turning Center EMCOTURN E25

8 Pages

-

CNC Lathe EMCOTURN E45

12 Pages

-

Emcoturn E65

13 Pages