Website:

EMCO GmbH

Website:

EMCO GmbH

Group: Emco

Catalog excerpts

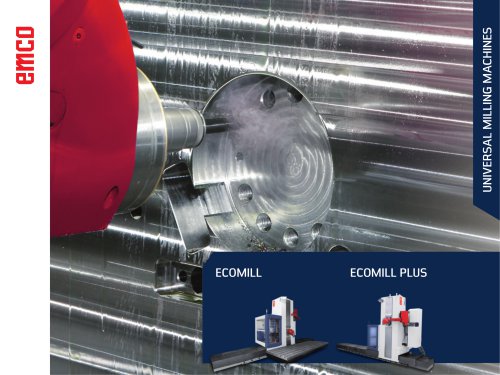

MAXXTURN 200 Universal turning centre for complete machining of shaft and chuck parts

Open the catalog to page 1

The solid Maxxturn 200 heavy-duty cutting machine can be used for turning and milling operations. Parts featuring a maximum length of 6000 mm and a diameter of 1000 mm are produced with ease and high efficiency. The machine is available in the following configurations: with 2 turrets (standard or mirror-inverted version), with tailstock or equipped with a counter spindle. / Ergonomic, swivel-mounted and movable control panel / Sinumerik 840D sl with 22“ colour display / Comprehensive machining cycles / 3D simulation / USB interface, 230 V socket / EMCONNECT / EMCO technology cycles...

Open the catalog to page 2

HIGHLIGHTS / xtremely robust design E / aximum machining accuracy M / igh rapid traverse speeds H / table Y-axis with large travel S (MT200 +/- 125 mm) / C steady rest, tailstock or counter N spindle as standard / ydraulic spindle brake H MODULAR SYSTEM TAILSTOCK / COUNTER SPINDLE The Maxxturn 200 comes in modular design. Different upgrading levels allow everything from simple turning to the expansion to a turning and milling centre with versatile application possibilities. Different spindle concepts with C-axis and high torque are used for this purpose. The machine is equipped with an...

Open the catalog to page 3

NETWORKS ARE CREATED INDIVIDUALLY OUR SOLUTIONS AS WELL Staying in touch is important not only among human beings. Persons, machines and the whole production environment must also be connected perfectly and safely in order to ensure efficient procedures during the production process. With EMCONNECT, the machine is optimally equipped for this purpose. The optional EMCONNECT Digital Services offer innovative online services for optimized machine operation. The user has always the control of the machine status. The automatic notification in case of malfunctions or standstill of the machine as...

Open the catalog to page 4

Process CAM CAMDigitale planning programming Prozessplanung Programmierung Digital Digitaler twin Zwilling Digital Rüsten set-up Simple and fast process validation of machine, fixture and tools Digital twin of the machine for workshop-oriented programming in work preparation / Tools can be easily guided over the workpiece without NC code / 100% identical with machine incl. control and machine-specific parameters / Detection of collisions and axis end positions / Original virtual control (Siemens, Heidenhain) / Reliable detection of collisions and syntax errors in advance / Simple and...

Open the catalog to page 5

MT200 – The master/slave motor arrangement, which also serves as the C-axis, has been implemented with the EMCO spindle concept. The motors run in sync, guarantee compensation for play and make it possible to achieve the performance values and torques mentioned below (see diagrams). Additionally, the two motors are equipped with ZF Duoplan Two-Speed Gearboxes. This results in high torques in the lower speed range and in high speeds in the upper speed range. Thus, it is possible to make optimal use of the cutting capacity provided by modern tools. Different, standardised turret/spindle...

Open the catalog to page 6

Data indicated in millimetres FLOOR PLAN Data indicated in millimetres FLOOR PLAN

Open the catalog to page 7

WORK ZONE TECHNICAL DATA C-axis with A2-11“ spindle Resolution of the rotary axis Distance between centres (spindle nose to center punch tip) Max. workpiece weight (overhung) Max. workpiece weight between tailstock and chuck (incl. chuck) Tool mover (standard version) Number of tool positions (all driven) Tool holder Tool mover Speed range Drive performance Main spindle – A2-15“ DIN 55026 (ZF gearbox) Feed drives Rapid traverse speed X / Z / Y Feed force X-axis Max. capacity, AC hollow spindle motor Feed force Z-axis Feed force Y-axis Spindle bearing (inner diameter, front) Tailstock with...

Open the catalog to page 8

EMCO GmbH / Salzburger Str. 80 / 5400 Hallein-Taxach / Austria / T +43 6245 891-0 / F +43 6245 86965 / info@emco.at www.emco-world.com EN9075 . 09/21 . Subject to technical modifications. No liability accepted for printing and typesetting errors. beyond standard

Open the catalog to page 10All EMCO GmbH catalogs and technical brochures

-

Turn Mill Assist

3 Pages

-

FlexLoader

3 Pages

-

Fyler Product overview

8 Pages

-

INDUSTRIAL TRAINING

25 Pages

-

CNC Lathe MAXXTURN 45

10 Pages

-

HYPERTURN 65 PM HP

9 Pages

-

Universal Machining Centre

9 Pages

-

CNC Lathe Maxxturn 25

9 Pages

-

CNC Lathe Maxxturn 45

10 Pages

-

EMCO Vertical Turning Machines

15 Pages

-

EMCOMAT E-200 MC

6 Pages

-

CNC Lathe S45

3 Pages

-

CNC Lathe S65

3 Pages

-

MEDICAL TECHNOLOGY

14 Pages

-

Turning Center EMCOTURN E25

8 Pages

-

CNC Lathe EMCOTURN E45

12 Pages

-

Emcoturn E65

13 Pages