Website:

EMCO GmbH

Website:

EMCO GmbH

Group: Emco

Catalog excerpts

MAXXTURN 65-1000 Universal turning center for complete machining of bar stock and chuck work

Open the catalog to page 1

Featuring a clever, modular design, the MAXXTURN 65-1000 offers many possibilities when it comes to meeting specific customer requirements. Two structurally identical and powerful turning spindles offer the basis for unlimited complete machining. A tool turret on the cross slide with optional Y-axis ensures the requisite flexibility. Each of the tool turret‘s positions is able to hold both stationary and driven milling and drilling heads. The optionally available BMT turret with water-cooled direct drive makes it possible to produce turned/ milled parts, which are machined predominantly...

Open the catalog to page 2

/ high performance and water cooled 2 spindle motors / 2-station turret with VDI 30 / 40 quick1 change system / ptional with BMT-turret and direct drive O up to 12000 rpm / -axis with 100 mm stroke for processing Y of complex turned/milled parts / ar stock feed up to ø 95 mm B / ptimum chip flow and user-friendly O work area INTEGRATED SPINDLE MOTOR (ISM) PARTS CATCHER The latest synchronous technology guarantees the highest dynamics and an exceptional torque in a compact design. Liquid cooling in conjunction with automatic temperature control maintains a constant temperature for all...

Open the catalog to page 3

NETWORKS ARE CREATED INDIVIDUALLY OUR SOLUTIONS AS WELL Staying in touch is important not only among human beings. Persons, machines and the whole production environment must also be connected perfectly and safely in order to ensure efficient procedures during the production process. With EMCONNECT, the machine is optimally equipped for this purpose. The optional EMCONNECT Digital Services offer innovative online services for optimized machine operation. The user has always the control of the machine status. The automatic notification in case of malfunctions or standstill of the machine...

Open the catalog to page 4

The EMCO short bar loaders. Universal and powerful. SHORT AND TO THE POINT. The EMCO SL 1200 is the perfect solution for automatic feeding and loading of cut-to-length bars. The key advantages are a small footprint and rapid loading times resulting from shorter strokes. for service purposes. Besides, it can comfortably be incorporated into the production process using the machine control‘s programme input masks. Minimum setup efforts are required when switching over to other bar diameters. The technology. The SL 1200 can be used immediately as a “plug-and-play” solution. Their extremely...

Open the catalog to page 5

THE EMCO GANTRY LOADER. INDIVIDUAL PROCESS OPTIMIZATION. Workpiece magazine Blank-specific pallet attachments enable oriented loading of blanks into the machine and increase the parts stock for unmanned production. Changeover times are reduced or eliminated thanks to the perfect adjustment to the customer‘s parts. GANTRY LOADER PALLET MAGAZINE (with 20 stations) GRIPPER SYSTEM 2 x 3-jaw double gripper head 4-station pallet attachment for tees 6-station pallet attachment for articulated brackets Multi-pallet attachment for a family of parts ADVANTAGES / Fully automatic loading and /...

Open the catalog to page 6

WORKSPACE Maxxturn 65-1000 with VDI 30

Open the catalog to page 7

MACHINE LAYOUT Machine layout Maxxturn 65-1000 BigBore Standard Kennlinie für Spindel ø65 und Spindel ø77 M [Nm] BigBore Standard Main and counter spindle ø 65 / 76,2 mm Performance and torque tool turret - driven tools VDI 30/40 Performance and torque tool turret - driven tools BMT55P

Open the catalog to page 8

Work area Driven tools Speed range Swing over cross slide Distance between spindle noses Drive power Maximum turning diameter Driven tools Turret with BMT-interface and direct drive Number of tool positions Precision interface Tool cross-section for square tools Shank diameter for boring bars Tool change time Speed range of the driven tools Torque of the driven tools Driving power of the driven tools Main spindle Speed range Maximum torque Spindle bearing (inside diameter) Spindle bore (excluding draw-back rod) Counter spindle Speed range (infinitely variable) Maximum torque Spindle bearing...

Open the catalog to page 9

EMCO GmbH / Salzburger Str. 80 / 5400 Hallein-Taxach / Austria / T +43 6245 891-0 / F +43 6245 86965 / info@emco.at www.emco-world.com EN 9064 . 06/22 . Technical modifications reserved. Errors and omissions excepted. beyond standard

Open the catalog to page 10All EMCO GmbH catalogs and technical brochures

-

Turn Mill Assist

3 Pages

-

FlexLoader

3 Pages

-

Fyler Product overview

8 Pages

-

INDUSTRIAL TRAINING

25 Pages

-

CNC Lathe MAXXTURN 45

10 Pages

-

HYPERTURN 65 PM HP

9 Pages

-

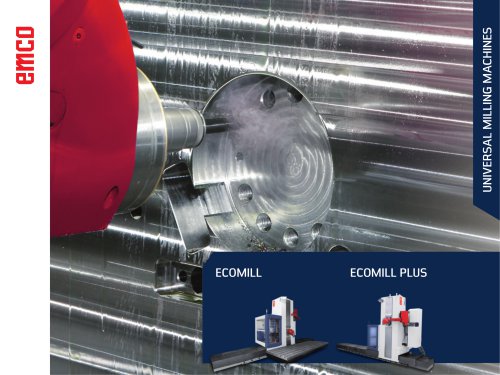

Universal Machining Centre

9 Pages

-

CNC Lathe Maxxturn 25

9 Pages

-

CNC Lathe Maxxturn 45

10 Pages

-

EMCO Vertical Turning Machines

15 Pages

-

EMCOMAT E-200 MC

6 Pages

-

CNC Lathe S45

3 Pages

-

CNC Lathe S65

3 Pages

-

MEDICAL TECHNOLOGY

14 Pages

-

Turning Center EMCOTURN E25

8 Pages

-

CNC Lathe EMCOTURN E45

12 Pages

-

Emcoturn E65

13 Pages