Website:

EMCO GmbH

Website:

EMCO GmbH

Group: Emco

Catalog excerpts

HYPERTURN 45 G3 High-performance turning center for complete machining

Open the catalog to page 1

HIGHLY PRODUCTIVE AND YET EXTREMELY FLEXIBLE Now in its third generation, the new HYPERTURN 45-G3 stands out by merging a significantly larger work area with compact design. This enables the integration of a 12-or 16-station turret with direct drive and BMT interface. The basic machine still features a VDI25 servo turret with quick-change interface, which is why many customers may continue to use their existing tool holders. Although the machine now offers a speed range of 0-8000 rpm, the tried and tested two-piece base structure remains unchanged. This makes it possible to achieve high...

Open the catalog to page 2

TOOL TURRET / 2 x 12-station VDI25 turrets / 2 x 12-station / 16-station turrets BMT45P / No alignment of the tool holder / Can be used flexibly on both spindles / Swivel speed adjustable with override ROLLER GUIDES HYPERTURN 45-G3 main spindle / counter spindle COUNTER SPINDLE / Wide speed range / C-axis for milling operations / Spindle clamp / A2-5 spindle nose / Full clamping system with parts ejector ø 45 mm / Programmable clamping stroke monitor MAIN SPINDLE / Wide speed range / C-axis for milling operations / A2-5 spindle nose / Hollow clamping system ø 45 (51/65) mm / Programmable...

Open the catalog to page 3

/ Large work area / Highly dynamic drives in all axes / Two powerful work spindles / 12-station/16-station tool turret with impressive milling performance / Stable Y-axis with 80 mm travel / emcoNNECT process assistant for Siemens 840D sl / Fanuc 31ib with 22“ multi-touch screen / Compact dimensions MAIN SPINDLE Rapid 12-fold servo turrets with very short cycle times for standardised VDI25 tools. All stations may accommodate driven tool holders for drilling, milling or thread-cutting operations. The operator may influence the swing speed at any time. For economical production of complex...

Open the catalog to page 4

TECHNICAL HIGHLIGHTS HOLDING BRAKE ON THE MAIN AND COUNTER SPINDLE It is always the respective C-axis which is positioned for milling and drilling operations. Additionally, however, it is possible to clamp each spindle in any position. Ergonomically arranged on the right-hand side of the workroom, the operating panel makes it possible to operate the HYPERTURN 45 conveniently. The operating panel is height-adjustable within a range of +/- 100 mm and may moreover be rotated by up to 50°. The screen has a 12° tilt, which ensures glare-free work in production environments with bright ceiling...

Open the catalog to page 5

Staying in touch is important not only among human beings. Persons, machines and the whole framework of production must also be connected perfectly and safely in order to ensure efficient procedures during the production process. With EMCONNECT you have the key to optimized connectivity for a digital factory. Perfectly integrated into numerical control, EMCONNECT enhances this type of system by its powerful functions for the modern generation of controllers (SIEMENS, HEIDENHAIN, FANUC). Control Dashboard Machine Data System Integration into control EMCONNECT offers several possibilities of...

Open the catalog to page 6

The EMCO short bar loaders. Universal and powerful. SHORT AND TO THE POINT. / Ing. Johann Brisker Brisker GmbH "All EMCO turning machines are automated with short bar or bar loaders, which frees up employees for other tasks and, as a consequence, increases productivity." The EMCO SL1200 is the perfect solution for automatic feeding and loading of cut-to-length bars. The key advantages are a small footprint and rapid loading times resulting from shorter strokes. for service purposes. Besides, it can comfortably be incorporated into the production process using the machine control's programme...

Open the catalog to page 7

THE EMCO SWING LOADER. THE INTEGRATED SOLUTION. The EMCO swing loader is a universal loading system for all types of preformed blanks. It can be customized individually to the customer’s requirements using numerous gripper and handling systems. How we do it: we standardize the components but create a customized solution. The result: a custom-tailored machine for the same price as a standard unit. Blank feeding systems, gripper and handling systems Feed systems specific to particular blanks allow preformed workpieces to be loaded in the working spindle correctly oriented, which enables...

Open the catalog to page 8

THE EMCO GANTRY LOADER. INDIVIDUAL PROCESS OPTIMIZATION. Workpiece magazine Blank-specific pallet attachments enable oriented loading of blanks into the machine and increase the parts stock for unmanned production. Changeover times are reduced or eliminated thanks to the perfect adjustment to the customer‘s parts. GANTRY LOADER PALLET MAGAZINE (with 20 stations) GRIPPER SYSTEM 2 x 3-jaw double gripper head 33-jaw 4-station pallet attachment for tees 6-station pallet attachment for articulated brackets Multi-pallet attachment for a family of parts ADVANTAGES / Fully automatic loading and...

Open the catalog to page 9

FINISHED PARTS CONTAINER PARTS CATCHER The tool gauge allows tools to be measured quickly and accurately on both turrets in the work area. It is mounted manually in the holder in the work area and, after use, is replaced in a storage space in the machine housing. BAND FILTER SYSTEM WITH HIGH-PRESSURE COOLANT PUMPS The HYPERTURN 45’s pneumatic parts catcher is controlled using M-functions. When needed, it traverses to the front of the work area and travels to the spindle center. The finished part is removed from the clamping device and transferred to the catcher tray. The parts catcher then...

Open the catalog to page 10

MACHINE LAYOUT AND FLOOR PLAN Machine layout HT45-G3 with EMCO SL1200 Floor plan HT45-G3 with EMCO SL1200 and paper band filter system MACHINE LAYOUT AND FLOOR PLAN

Open the catalog to page 11

WORK AREA HT45-G3 mit 12-fach Work area HT45-G3 with BMT45P Revolver 16-station BMT45P turret Work area HT45-G3 with 12-station VDI25 turret WORK AREA Work area HT45-G3 with 12-station BMT45P turret MACHINE LAYOUT AND WORK AREA

Open the catalog to page 12

TECHNICAL DATA Tool turrets, VDI / BMT Swing over bed 0 430 mm Driven tools, VDI / BMT Slide travel in X / X2 Slide travel in Z / Z2 / Z3 Travel in Y Speed range Torque Drive performance Number of driven tools Main spindle Feed drives Speed range 0 - 7000 rpm Spindle bearing (inner diameter at front) 0 85 mm Resolution of the rotary axis 0,001° Rapid motion speed 1000 rpm Spindle indexing (disc brake) 0,01° Coolant pumps for the tool turrets 2 x 14 bar Flushing pumps for the work area 2 x 3,7 bar Height of center above floor 1240 mm Space occupied BxT (not including chip conveyor and...

Open the catalog to page 13All EMCO GmbH catalogs and technical brochures

-

Turn Mill Assist

3 Pages

-

FlexLoader

3 Pages

-

Fyler Product overview

8 Pages

-

INDUSTRIAL TRAINING

25 Pages

-

CNC Lathe MAXXTURN 45

10 Pages

-

HYPERTURN 65 PM HP

9 Pages

-

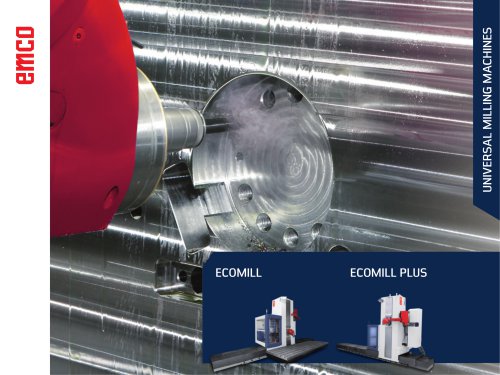

Universal Machining Centre

9 Pages

-

CNC Lathe Maxxturn 25

9 Pages

-

CNC Lathe Maxxturn 45

10 Pages

-

EMCO Vertical Turning Machines

15 Pages

-

EMCOMAT E-200 MC

6 Pages

-

CNC Lathe S45

3 Pages

-

CNC Lathe S65

3 Pages

-

MEDICAL TECHNOLOGY

14 Pages

-

Turning Center EMCOTURN E25

8 Pages

-

CNC Lathe EMCOTURN E45

12 Pages

-

Emcoturn E65

13 Pages