Website:

EMCO GmbH

Website:

EMCO GmbH

Group: Emco

Catalog excerpts

HYPERTURN 100 PM Turning and milling center for the complete machining of complex workpieces

Open the catalog to page 1

MAIN AND COUNTER SPINDLE / Dual drive motor for a backlash free C-axis (A2-11“) / Integrated spindle motor with C-axis (A2-8“) / Impressive performance values (A2-8“/A2-11“): 33/53 kW - 800/4400 Nm - 3500/2500 rpm / Liquid cooling with automatic temperature regulation MILLING SPINDLE / Slat band conveyor / Chip ejection height 1130 mm / Coolant volume 500/600/700 l / Milling spindle pump 14 bar / Turret pump 14 bar / Two washing pumps of 7 bar / Moving column structure for high stiffness / Integrated B-axis / Excellent technical data: 165 Nm, 33.8 kW, 12000 rpm / Integrated torque motor /...

Open the catalog to page 2

Main and counter spindle A2-8“ Leistungskurve für Gegenspindel Milling spindle (standard version) HSK63/PSC63 Milling spindle HSK-T100 (optional) / Chain magazine with 40/100/120 tool stations / Space-saving integrated in the basic machine / Servocontrolled swivel arm changer / Short changing times / Max. tool length 500 mm / Max. tool diameter 90 (150) mm / Max. tool weight 12 kg TOOL MAGAZINE Main spindle A2-11“ / Counter spindle A2-11“ with additional option / 11“ tandem drive solution with wide speed range / C-axis for milling operations up to 2800 Nm (11“) / 8“ Integrated spindle motor...

Open the catalog to page 3

/ utomatic tool default settings and A workpiece measuring probes / ne or several CNC-steady rest O / 0 / 100 tool magazine stations 4 / lexible milling spindle with 12000 rpm F / oring bar pick-up system B / imultaneous 5-axis machining S / igh pressure coolant: 80 bar H MILLING SPINDLE MAIN SPINDLE AND COUNTER SPINDLE (A2-11“) Featuring performance data that enable all types of machining without any compromises. The EMCO spindle concept comes with two servomotors that also act as a C-axis. The motors work synchronously, guarantee backlash compensation and enable the achievement of the...

Open the catalog to page 4

/ ery large work area for the complete V machining of large workpieces featuring a turning diameter of up to 720 mm and a maximum length of 3100 mm / owerful main spindle and counter spindle P / ynamic and precise B-axis with direct drive D as well as high torque and performance Sinumerik 840D sl with EMCONNECT MAIN SPINDLE MILLING SPINDLE High-quality spindle heads according to DIN 55026 with 8“ and 11“ ensure high force and very good clamping accuracy. The B-axis of the HYPERTURN 100 Powermill is for state-of-theart milling processes such as 5-axis machining, HSC or HPC machining...

Open the catalog to page 5

/ igh dynamics due to state-of-the-art H spindle motor technology / spindles liquid-cooled for optimum All thermal stability / igh productivity due to short tool change H times / oth tool systems can be used on both B spindles / ed design for maximum stability and B oscillation damping TOOL TURRET The compact direct drive high-performance motor is integrated in the tool disc. The drive of the tools takes place directly. Without gear train. Without gear train, gears and vibrations and almost noiseless. That means: more speed, more power, more productivity. Optionally, the tool can be...

Open the catalog to page 6

/ Glass scales in the linear axes X, Y and Z / Highest positioning accuracy / Set-up parallel to main time / Thermal and mechanical stability / High machining performance / Various milling spindle variants with more power and speed / Comprehensive technology as well as digitization possibilities WORKPIECE MEASURING PROBE Measuring probe for various tool holders allowing the automatic measuring of the workpiece in the work area with subsequent tool correction. With measurement set for check and correction of the kinematic accuracy of 5-axis machining. Different hydraulics steady rests are...

Open the catalog to page 7

EMCO solutions focus on customer-specific requirements. The perfect implementation of customer-specific requirements shortens production times. The compact installation dimensions of 8900 x 7200 mm optimally match the conditions in production. The robot head change with different grippers, the flexible self-centering solution for different parts, the combination of parts by the tool turret and the B-axis expand the system and meet the demand for high productivity. Pallet scanner by blanks enable oriented loading of blanks into the machine and increase autonomy for unattended production. In...

Open the catalog to page 8

Standard Apps NETWORKS ARE CREATED INDIVIDUALLY OUR SOLUTIONS AS WELL Staying in touch is important not only among human beings. Persons, machines and the whole production environment must also be connected perfectly and safely in order to ensure efficient procedures during the production process. With EMCONNECT, the machine is optimally equipped for this purpose. The optional EMCONNECT Digital Services offer innovative online services for optimized machine operation. The user has always the control of the machine status. The automatic notification in case of malfunctions or standstill of...

Open the catalog to page 9

INSTALLATION PLAN Installation plan HT 100 PM with cooling unit and band filter system Installation plan HT 100 PM with cooling unit and band filter system INSTALLATION PLAN

Open the catalog to page 10

Layout HT 100 PM and side view Steady rest K5.1 with counter spindle, turret BMT65P * Various workspace solutions with options on request WORK AREA

Open the catalog to page 11

Work area Tool magazine 800 mm (without tool turret) Tool magazine stations 720 mm (with milling spindle) Length between spindle and centre Max. turning tool weight Milling spindle - Powermill Coolant system Speed range Max. torque Main spindle - counter spindle Spindle connection (DIN 55026) Coolant pressure (max. milling spindle / tool turret) Flushing system in the work area Cooling tank capacity Power chuck diameter Max. spindle speed (11" with transmission) Max. drive power, main spindle Max. torque (11" with transmission) Travel range Max. weight incl. chuck Detend torque of clamp...

Open the catalog to page 12

EMCO GmbH / Salzburger Str. 80 / 5400 Hallein-Taxach / Austria / T +43 6245 891-0 / F +43 6245 86965 / info@emco.at www.emco-world.com EN9067 . 08/22 . Technical modifications reserved. Errors and omissions excepted. beyond standard

Open the catalog to page 13All EMCO GmbH catalogs and technical brochures

-

Turn Mill Assist

3 Pages

-

FlexLoader

3 Pages

-

Fyler Product overview

8 Pages

-

INDUSTRIAL TRAINING

25 Pages

-

CNC Lathe MAXXTURN 45

10 Pages

-

HYPERTURN 65 PM HP

9 Pages

-

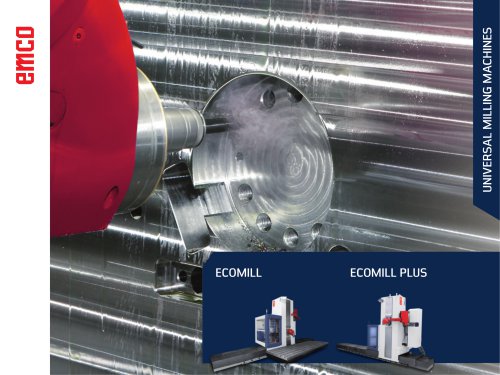

Universal Machining Centre

9 Pages

-

CNC Lathe Maxxturn 25

9 Pages

-

CNC Lathe Maxxturn 45

10 Pages

-

EMCO Vertical Turning Machines

15 Pages

-

EMCOMAT E-200 MC

6 Pages

-

CNC Lathe S45

3 Pages

-

CNC Lathe S65

3 Pages

-

MEDICAL TECHNOLOGY

14 Pages

-

Turning Center EMCOTURN E25

8 Pages

-

CNC Lathe EMCOTURN E45

12 Pages

-

Emcoturn E65

13 Pages