Website:

EMCO GmbH

Website:

EMCO GmbH

Group: Emco

Catalog excerpts

EMCOTURN E45 CNC turning center for bar stock work up to Ø 45 (51) mm and chucking work

Open the catalog to page 1

1 WORK AREA / Plenty of open space / Straight chip fall / Top ergonomics Perfect European engineering, superbly equipped with a Y axis, 200 mm more machining length, C axis, driven tools with a 4 kW drive performance and a choice of a Siemens, Fanuc or Heidenhain control unit. A cost-effective bar loader package or an integrated automation solution is available on request. 2 TOOL TURRET / 12 stations VDI 30 axial / 6 stations driven / Tapping without length compensation / Polygonal turning, engraving, etc. 3 SPINDLE / High drive performance / Thermoresistant construction / Large speed range...

Open the catalog to page 2

1 WORK AREA / Plenty of open space / Straight chip fall / Top ergonomics 6 CONTROL UNIT / State-of-the-art control technology / FANUC 0iTF / 15" incl. Manual Guide i / SINUMERIK 828D / 10,4" incl. Shop Turn / HEIDENHAIN CNC PILOT 640 / 15,6" incl. Smart Turn SPiNDLE VERSiON The EMCOTURN E45 SMY. The perfect solution for economic, off-the-shelf complete machining. Fitted with a counter spindle, driven tools, a high-precision C axis and fast rapid motion speeds, the EMCOTURN E45 SMY gives you everything you need for manufacturing complex turned-milled parts efficiently and at a low price. The...

Open the catalog to page 3

i MAiN SPiNDLE / High drive power / Compact, thermostable construction / Large speed range / A2-5 spindle nose / Bar capacity diameter 45 mm (51) 2 MACHiNE BED / Extremely stiff welded steel fabrication / Compact structure / Very high thermostability / Filled with vibration-absorbing material 3 ROLLER GUiDES / In all linear axes / Preloaded / No backlash in any direction of force / High rapid motion speeds / No wear / Minimal lubrication 4 TOOL TURRET / VDI quick change system / 12 driven tool stations / No alignment of the tool holder / Can be used on both spindles / Swivel speed...

Open the catalog to page 4

/ Powerful driven tools / Y-axis for complexe milling operations / Counter spindle for complete machining / Flexible automatic tailstock / Excellent machining precision / ery compact machine layout V / State-of-the-art control technology from Siemens, Fanuc or Heidenhain incl. Shop Turn / Manual Guide i / Smart Turn Main spindle The counter spindle is available for complete machining of the workpieces. This allows turning, milling and drilling operations to be carried out on the back of the workpieces. The concentric transfer of the workpieces also has the advantage that very high...

Open the catalog to page 5

The CNC control unit: The brains of each CNC lathe The CNC-series 0iTF model is the ideal solution for compact high-end lathes. An attractive price-performance ratio teamed with unmatched dynamics, precision and reliability. This control unit is characterised by easy operation and programmability. Using the FOCAS interface, it can easily be connected to higher-level IT systems, whilst offering maximum performance and functionality. Easy and rapid automation by means of a robot or gantry loader is guaranteed. EMCO diagnostic images Machine tools are facing ever-increasing requirements. They...

Open the catalog to page 6

THE EMCO SWING LOADER. THE INTEGRATED SOLUTION. The EMCO swing loader is a universal loading system for all types of preformed blanks. It can be customized individually to the customer’s requirements using numerous gripper and handling systems. How we do it: we standardize the components but create a customized solution. The result: a custom-tailored machine for the same price as a standard unit. Blank feeding systems, gripper and handling systems Feed systems specific to particular blanks allow preformed workpieces to be loaded in the working spindle correctly oriented, which enables...

Open the catalog to page 7

Holding brake on main and counter spindle Spindle extension for short bar loader For milling and drilling operations, the respective C axis is always positioned. However, each spindle can also be clamped in any position. The spindle extension can be offered for processing cut-tolength material bars up to a length of 1200 mm. The cut-tolength bar material can then be fed fully automatically with the SL1200. BAND-PASS FILTER UNIT EMCO short loader Material support Operating panel If required, it is possible to install an optional 600-litre band-pass filter unit with 25 bar high-pressure...

Open the catalog to page 8

work area Machine layout E45 with EMCO SL1200 work area Work area E45 with tailstock Work area E45 with counter spindle MACHINE LAYOUT

Open the catalog to page 9

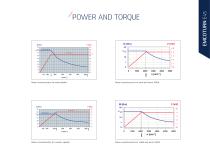

Motorkennlinie Gegenspindel (Option) Fanuc Kennlinie für angetriebene Werkzeuge M [Nm] P [kW] Motor characteristics for main spindle Motor characteristics for axial tool turret VDI30 n [min-1] (angetriebene Werkzeuge) Motor charasteristics for counter spindle Motor characteristics for radial tool turret VDI25

Open the catalog to page 10

Swing over bed Swing over cross slide Distance between centers Distance between spindle noses f. counter spindle version 720 mm Max. turning diameter with axial turret with radial turret Maximum part length Maximum bar-stock diameter Travel Spindle Speed range Spindle torque Spindle nose DIN 55026 Spindle bearing (inner diameter at front) Spindle bore Counter spindle Speed range Spindle torque (Siemens / Fanuc) Spindle nose DIN 55026 Spindle bearing (inner diameter at front) C-axis Resolution Rapid motion speed Spindle indexing TECHNICAL DATA Automatic tailstock Coolant system Travel 510 mm...

Open the catalog to page 11

EMCO GmbH / Salzburger Str. 80 / 5400 Hallein-Taxach / Austria / T +43 6245891-0 / F +43 624586965 / info@emco.at www.emco-world.com DE4543 . 05/20 . Technical modifications reserved. Errors and omissions excepted. beyond standard

Open the catalog to page 12All EMCO GmbH catalogs and technical brochures

-

Turn Mill Assist

3 Pages

-

FlexLoader

3 Pages

-

Fyler Product overview

8 Pages

-

INDUSTRIAL TRAINING

25 Pages

-

CNC Lathe MAXXTURN 45

10 Pages

-

HYPERTURN 65 PM HP

9 Pages

-

Universal Machining Centre

9 Pages

-

CNC Lathe Maxxturn 25

9 Pages

-

CNC Lathe Maxxturn 45

10 Pages

-

EMCO Vertical Turning Machines

15 Pages

-

EMCOMAT E-200 MC

6 Pages

-

CNC Lathe S45

3 Pages

-

CNC Lathe S65

3 Pages

-

MEDICAL TECHNOLOGY

14 Pages

-

Turning Center EMCOTURN E25

8 Pages

-

Emcoturn E65

13 Pages