Catalog excerpts

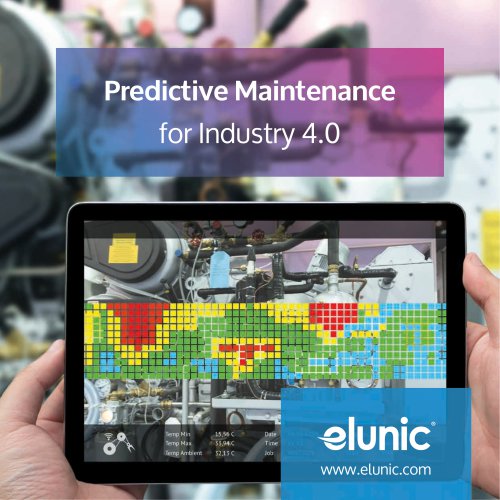

Predictive Maintenance for Industry 4.0

Open the catalog to page 1

Project 'Zero Downtime': How to Start Predictive Maintenance Regular maintenance and inspections have been the order of the day to ensure the maintenance of all equipment, machines, components or technical devices in general. In the age of Industry 4.0, these precautionary measures are supplemented and substantially enhanced by Predictive Maintenance (PdM). This proactive type of maintenance is almost symbolic for Industry 4.0 and promises the greatest success. "These days, you don't fix things when they break but right before they break." More Than Just a New Type of Maintenance One of the...

Open the catalog to page 2

6 Steps to Your Successful Predictive Maintenance Project Reduction of Service Times and Costs through Predictive Maintenance Anyone who introduces predictive maintenance must solve all the sub-problems of Industry 4.0: From networking and storage to business logic. This requires the right approach: • Define Project Goal Increasing uptime or optimizing spare part logistics are some examples of possible project goals. • Identifying Stakeholders Be it shop floor workers, IT or the workers' council: a strategic project, such as predictive maintenance, requires the cooperation and participation...

Open the catalog to page 3

elunic AG: I4.0 Competence for SMEs Every company must face the digital transformation trend and make the transition from a traditional machine manufacturer to a software company. The project management should be carried out internally to build up competency in-house. With an experienced I4.0 service provider like elunic, companies can accelerate their digitization process considerably. We also support you in choosing the right technology and the best methodical approach from the wide range of possible options. Successful companies have chosen elunic as their business partner, because: •...

Open the catalog to page 4