Website:

Eltex-Elektrostatik-GmbH

Website:

Eltex-Elektrostatik-GmbH

Catalog excerpts

in the past, Eitex Remois- Technical Information tening systems have guaranteed high quality printed products mainly on fastrunning and wide machines. The WEBMOISTER 3000 ensures high-quality products in all heatset web offset machines. Using a new nozzle concept, both lighter and heavier grammages can be remoistened at all web speeds with ultimate precision and homogeneity. The new pneumatic atomizing nozzles are capable of applying smallest water quantities without developing waste water. The modular structure of the nozzle bar allows the WEBMOISTER 3000 to remoisten paper webs in widths of as much as 3meters. The benefits: • better quality of the printed product • enhanced productive efficiency through easier finishing of the paper • cost savings through more efficient processes • small dimensions • easy operation • minimum cost of ownership WEBMOISTER 3000 Electrostatic Remoistening a* o o N

Open the catalog to page 1

System Description WEBMOISTER 3000 Electrostatic Remoistening by Eltex Inks in heatset web offset are dried with hot air. In general, this process lowers the water content of the paper, sometimes to such an extent that the paper dries out completely. This can cause severe problems in finishing. Electrostatic remoistening raises the water content of the paper back to the original (and necessary) value. The benefits of the system: • easier processing and handling of perfect-bound products with cross-grain or long-grain pages • no waves caused by gluing • no fiber breakage • optimum paper run...

Open the catalog to page 2

Function principle 1 Nozzle bar 2 Charging bar 3 Aerosol path 4 Pneumatic atomizing nozzles 5 Paper web

Open the catalog to page 3

Water content of the paper Most papers used in heatset web offset printing are delivered with a water content of between 4 and 5%. During printing, this percentage tends to increase by about half a percent. The subsequent drying step lowers the water content, sometimes desiccating the paper completely. When setting the water quantity for remoistening, the paper grade and the grammage must be taken into account. The system notes all the data through the appropriate setpoint settings. The WEBMOISTER 3000 allows even the smallest water quantities to be metered exactly. The result: ultimate...

Open the catalog to page 4

High voltage field The reliable Eltex charging bar is used to generate the high voltage field. The shockless bar guarantees the optimum field build-up and field distribution. The actual high voltage is generated by an Eltex high voltage generator. With its new connection concept and by monitoring important functions (high voltage cascade, calibration, short circuit current, voltage and current limitation), the generator provides ultimate standards of safety. Operation The system is operated and controlled via a touch screen. Key symbols with unique function assignments guide the operator...

Open the catalog to page 5

A Remote Control B Supply module C Nozzle bar D Charging bar E Base frame 1 Mains lead to the supply module 2 Mains lead ESC2 3 Customer interface to the control cabinet 4 CAN-bus leads 5 Water connection 6 Ground lead ESC2

Open the catalog to page 6

Static Control ESC2/EEW built-in version Remote control ESC2/EEW The Static Control Type ESC2/EEW is designed for installation in the control desk. The system is operated via touch screen remote control, allowing the operator to make all necessary adjustments and settings. The system settings are read out at the remote control. The display shows the operator the status, the proper function and any malfunctions of the system. By touching the symbols on the screen, the system or its individual components can be enabled / disabled or specific items of information can be accessed. The following...

Open the catalog to page 7

Technical specifications ESC2/EEW (built-in version 6.5") Supply voltage Power input Ambient operating temperature Built-in in angle 90° to 45° Built-in in angle 44° to 20° Built-in in angle 19° to 0° Storage temperature Ambient humidity Enclosure Protection class Dimensions Weight Operation 24 V DC; supplied by Eltex control cabinet max. 20 W at 24 V DC 0...+45°C (+32...+113 °F) (vertical) 0...+40°C (+32...+104°F) 0...+35°C (+32...+95°F) (horizontal) -20...+60 °C (-4...+140°F) 80 % rh max., non-dewing zinc-plated sheet steel plating front IP65, computer unit IP20 assembly recess opening:...

Open the catalog to page 8

Static Control ESC2/GEW and ESC2/NEW (enclosure version 6.5") 'UHKZLQNHO s DQJOH RI URWDWLRQ s $QJOH GH URWDWLRQ s $QVLFKW YLHZ YXH YLVWD : *Öffnung zur Kabeldurchführung Opening for cable entry Ouverture pour passage de câbles Apertura per ingresso cavi Dimensions Static Control Type ESC2/GEW (base shown in broken outline) and Static Control Type ESC2/NEW The Static Control Type ESC2/GEW is designed for free-standing installation. The unit is equipped with an assembly base and can be mounted as a machine add-on unit , against a wall or on the floor. The unit can be turned by 10° around its...

Open the catalog to page 9

Control cabinet with supply modules Aspect of the control cabinet, supply modules and external dimensions The entire range of control elements of the system is installed in the control cabinet. The cabinet is designed for direct mounting to the base frame of the remoistening system. It includes the following components: • water flow controller for stepless water quantity control • high voltage generator • power supply and switchgear components • sensors • water supply with stop valve, pressure reducer and water filter for supplying the nozzles • side channel condenser.

Open the catalog to page 10

A Remote control B Supply module 1 Supply voltage, fuses 2 24 V DC for remote control 3 Customer interface to the control cabinet 4 CAN-Bus leads 5 Water connection

Open the catalog to page 11

Power supply data and safety engineering Eltex offices and agencies The addresses of all Eltex agencies can be found on our website at www.eltex.com eltex electrostatic innovations eMail systems@eltex.com Internet www.eltex.com \ >

Open the catalog to page 12All Eltex-Elektrostatik-GmbH catalogs and technical brochures

-

ELTEX CONNECTED CONTROL ECC

3 Pages

-

Technical information GNH63

56 Pages

-

Brochure ESA

15 Pages

-

Operating Manual TERRALIGHT

36 Pages

-

Brochure TERRALIGHT

3 Pages

-

Brochure Power Charger

5 Pages

-

POWER IONIZER - power supply

8 Pages

-

Technical information SDS

4 Pages

-

Brochure SDS

4 Pages

-

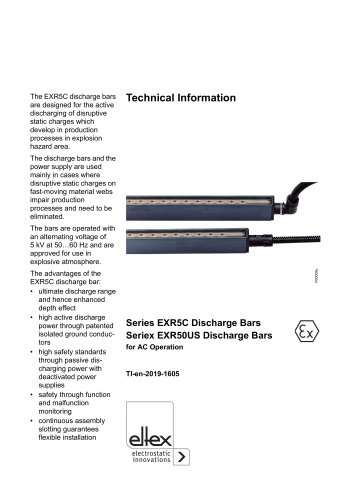

Technical information EXR5C

2 Pages

-

Technical information R45

2 Pages

-

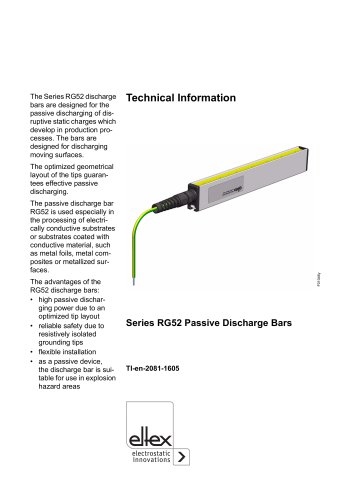

Technical information RG52

4 Pages

-

Brochure flexION

4 Pages

-

Technical information CB

4 Pages

-

Brochure STATICJET RX22

3 Pages

-

Technical information RX3

4 Pages

-

Brochure RX3

3 Pages

-

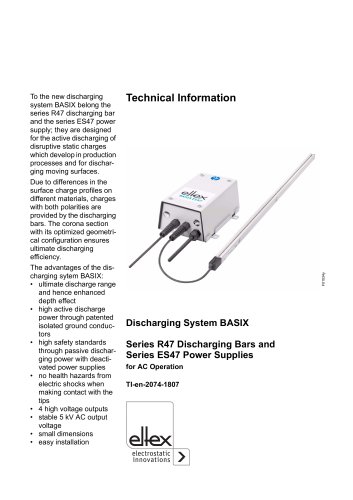

Brochure BASIX

4 Pages

-

Technical information ES24

4 Pages

-

Brochure WM3000

15 Pages

-

Technical information SCC

3 Pages

-

Brochure Discharging

7 Pages

-

Brochure SCC

3 Pages

-

Brochure Ion Blower

5 Pages

-

Brochure Discharging

7 Pages

-

Technical information R55

8 Pages

-

Technical information DM1500

8 Pages

-

Brochure DM1500

2 Pages

-

Brochure RX11

3 Pages

-

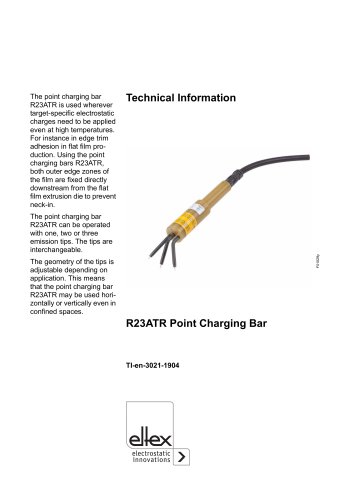

Technical information R23ATR

8 Pages

-

Brochure Charging bars

5 Pages

-

Brochure BASIX

4 Pages

-

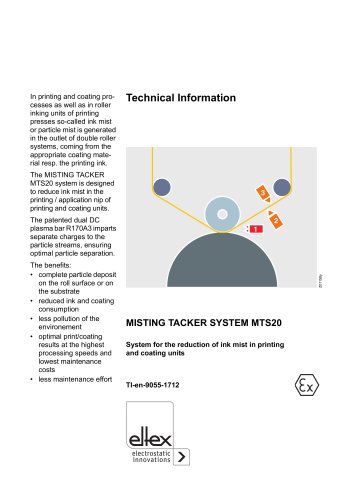

Technical information MTS

12 Pages

-

Brochure MTS

3 Pages

-

Brochure Cable reels

4 Pages

-

Brochure Grounding General

4 Pages

-

Technical information PGT120

4 Pages

-

Technical information GHH36

20 Pages

-

Brochure GHH36

2 Pages

-

Technical information ES53

4 Pages

-

Brochure Ground clamps

4 Pages

-

Brochure Grounding General

4 Pages

-

Technical information ES51

4 Pages

-

Technical information R55

8 Pages

-

Brochure Cable reels

4 Pages

-

Brochure Grounding General

4 Pages

-

Brochure Cable reels

4 Pages

-

Brochure Grounding General

4 Pages

-

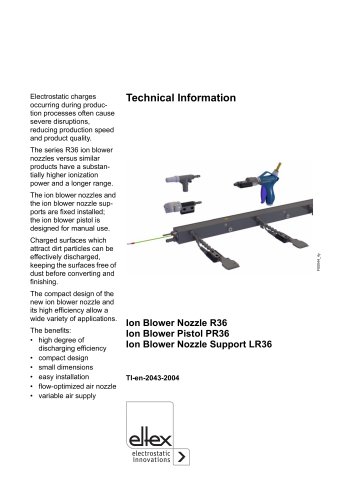

Technical information R36

8 Pages

-

Brochure Ion Blower

5 Pages

-

Brochure Terrapharm General

2 Pages

-

Brochure Grounding General

4 Pages

-

Brochure Terracap General

2 Pages

-

Brochure Grounding General

4 Pages

-

Technical information EM03

2 Pages

-

Brochure Charging bars

5 Pages

-

Brochure Ground clamps

4 Pages

-

Brochure Grounding General

4 Pages