Website:

Eltex-Elektrostatik-GmbH

Website:

Eltex-Elektrostatik-GmbH

Catalog excerpts

The GHH36 electrostatic ribbon tacking system is intended for use in folders and is designed to interlock the incoming paper webs using static electricity such that dog earings and creases are avoided. The charging electrodes are mounted after the multilayer rollers and ahead of the of the cross cutter. The paper webs run between the electrodes and are charged up in the process. The GHh36 ribbon tacking system is made in several different designs and can be installed in all commercial folders. Benefits: • copy collating without turned corners (with optimum mechanical setting of the collector cylinder) • less cutting differences • higher machine speeds • ultimate bundle formation • cost savings through better machine efficiency • good converting of the finished products Technical Information

Open the catalog to page 1

System Description GHH36 Ribbon Tacking by Eltex For trouble-free ribbon flow through the folders in publication and heat-set offset printing. The Eltex GHH36 Ribbon Tacking system is engineered to electrostatically "tack" the ribbons together. Located in the upper folder section, the system charges the ribbons, so that they attract one another and remain in position as they enter and easily pass throuhg the lower folder. Since the tacked ribbons flow much more smoothly through processing, production speeds go up, quality improves and waste is reduced. The system is designed for ribbon...

Open the catalog to page 2

Function Two high voltage generators generate positive and negative high voltages which are passed on to the charging electrodes mounted in the folder. The positive and negative electrodes are arranged in opposition to each other. The paper webs pass between the electrodes. Principle of electrostatic ribbon tacking system The electric charge applied by the system displaces the air between the ribbons, and results in a temporary, but highly intense bonding force between them. Reduced emission tip spacing of the new electrode bars generates maximum tacking power with minimum voltage levels. A...

Open the catalog to page 3

System Outline Fern bedi enun Rem g ote Con trol KNH FB Sollw ert Setp oint Hoch span High nung Volta On/O ge ff

Open the catalog to page 4

1 Remote control Static Control ESC2 or remote control ST-KNHFB The entire system is operated and controlled via the optional remote control (ESC2 via touch-screen). ESC2 options: ESC2MODEM: modem for remote maintenance, telephone and mains connection required. The remote control ESC2 allows to operate an Eltex Ribbon Tacking system together with an Eltex Electrostatic Printing Assist or an Eltex Remoistening unit via one remote control. 2 Remote control ST-KNHFB As an alternative to the Statice control ESC2 remote control, the whole system can be operated via the optional ST-KNHFB remote...

Open the catalog to page 5

Aspect of the Static Control ESC2/EEE / Cut-out section and dimensions of the installation B Area for connections and compact flash The system is controlled via the remote control unit. The system is operated directly on the monitor via touch screen where the necessary settings can be selected. The display shows the operator the status, the proper function and any error states of the system. By touching the appropriate symbol on the screen the system or individual components can be activated or deactivated or specific information can be retrieved. Technical Specifications ESC2/EEE Supply...

Open the catalog to page 6

Remote Control ESC2/EFE built-in version large Aspect of the Static Control ESC2/EFE / Cut-out section and dimensions of the installation B Area for connections and compact flash The system is controlled via the remote control unit. The system is operated directly on the monitor via touch screen where the necessary settings can be selected. The display shows the operator the status, the proper function and any error states of the system. By touching the appropriate symbol on the screen the system or individual components can be activated or deactivated or specific information can be...

Open the catalog to page 7

Dimensions Static Control ESC2/GEE (pedestal shown in broken outline) and ESC2/NEE The remote control ESC2/GEE has been designed for free-standing installation. The unit can be mounted as machine attachment component, against a wall or on the floor. The unit pivots around its vertical axis by 10° and is rotatable, allowing the best possible viewing angle to be selected. The remote control ESC2/NEE is a enclosure version without pedestal. Technical specifications ESC2/GEE and ESC2/NEE Supply voltage 24 V DC power supply unit 115/230 VAC, 50/60 Hz included Power input max. 20 W at 24 V DC...

Open the catalog to page 8

*Öffnung zur Kabeldurchführung Opening for cable entry Ouverture pour passage de câbles Apertura per ingresso cavi 'UHKZLQNHO s DQJOH RI URWDWLRQ s $QJOH GH URWDWLRQ s $QVLFKW YLHZ YXH YLVWD : Dimensions Static Control ESC2/GFE (pedestal shown in broken outline) and ESC2/NFE The remote control ESC2/GFE has been designed for free-standing installation. The unit can be mounted as machine attachment component, against a wall or on the floor. The unit pivots around its vertical axis by 10° and is rotatable, allowing the best possible viewing angle to be selected. The remote control ESC2/NFE is...

Open the catalog to page 9

Remote Control ST-KNHFB 1 Fern Rem bedien ote un KN H FB Con g trol 1 Operator interface, two-line display, keypad 2 Attachment for installation in control panel 3 Socket CAN bus (female) 4 Socket CAN bus (male) 5 Socket RS232 interface, malfunction 6 Socket supply voltage 7 Fuse (0,04 A, slow blow) 8 Master switch ON/OFF Hoc Hig hspa nnun hV ol On/ tage g Off Ho ch Highspan Vo nung On/ ltage Off Assembly of the remote control ST-KNHFB via the assembly bracket; cut-out for the installation of the control panel The remote control ST-KNHFB is available for remote operation and monitoring of...

Open the catalog to page 10

High Voltage Generator ST-KNH34 M6 Hoc Hig hs KN h V pann un H 34 olta gs ge Gen gene erat rato r or Installating the high voltage generator with assembly plate Terminal charging electrode Terminal charging electrode Socket analog interface Socket CAN bus female Ground terminal Socket CAN bus male Socket supply voltage Fuse (see name plate) Master switch ON/OFF Operator interface The high voltage generator ST-KNH34 supplies the charging bars with the required high voltage. The high voltage generator can be programmed either via the remote control ESC2, the remote control ST-KNHFB or...

Open the catalog to page 11All Eltex-Elektrostatik-GmbH catalogs and technical brochures

-

ELTEX CONNECTED CONTROL ECC

3 Pages

-

Technical information GNH63

56 Pages

-

Brochure ESA

15 Pages

-

Operating Manual TERRALIGHT

36 Pages

-

Brochure TERRALIGHT

3 Pages

-

Brochure Power Charger

5 Pages

-

POWER IONIZER - power supply

8 Pages

-

Technical information SDS

4 Pages

-

Brochure SDS

4 Pages

-

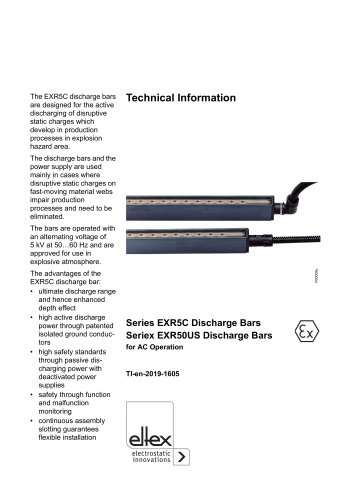

Technical information EXR5C

2 Pages

-

Technical information R45

2 Pages

-

Technical information RG52

4 Pages

-

Brochure flexION

4 Pages

-

Technical information CB

4 Pages

-

Brochure STATICJET RX22

3 Pages

-

Technical information RX3

4 Pages

-

Brochure RX3

3 Pages

-

Brochure BASIX

4 Pages

-

Technical information ES24

4 Pages

-

Technical information WM3000

12 Pages

-

Brochure WM3000

15 Pages

-

Technical information SCC

3 Pages

-

Brochure Discharging

7 Pages

-

Brochure SCC

3 Pages

-

Brochure Ion Blower

5 Pages

-

Brochure Discharging

7 Pages

-

Technical information R55

8 Pages

-

Technical information DM1500

8 Pages

-

Brochure DM1500

2 Pages

-

Brochure RX11

3 Pages

-

Technical information R23ATR

8 Pages

-

Brochure Charging bars

5 Pages

-

Brochure BASIX

4 Pages

-

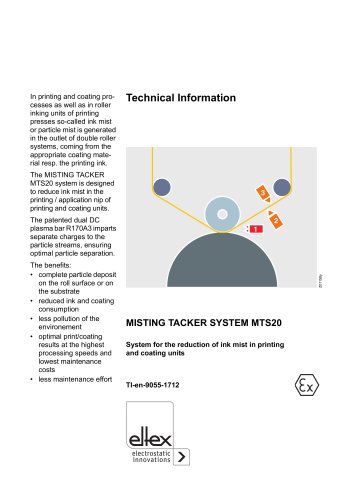

Technical information MTS

12 Pages

-

Brochure MTS

3 Pages

-

Brochure Cable reels

4 Pages

-

Brochure Grounding General

4 Pages

-

Technical information PGT120

4 Pages

-

Brochure GHH36

2 Pages

-

Technical information ES53

4 Pages

-

Brochure Ground clamps

4 Pages

-

Brochure Grounding General

4 Pages

-

Technical information ES51

4 Pages

-

Technical information R55

8 Pages

-

Brochure Cable reels

4 Pages

-

Brochure Grounding General

4 Pages

-

Brochure Cable reels

4 Pages

-

Brochure Grounding General

4 Pages

-

Technical information R36

8 Pages

-

Brochure Ion Blower

5 Pages

-

Brochure Terrapharm General

2 Pages

-

Brochure Grounding General

4 Pages

-

Brochure Terracap General

2 Pages

-

Brochure Grounding General

4 Pages

-

Technical information EM03

2 Pages

-

Brochure Charging bars

5 Pages

-

Brochure Ground clamps

4 Pages

-

Brochure Grounding General

4 Pages