Website:

Eltex-Elektrostatik-GmbH

Website:

Eltex-Elektrostatik-GmbH

Catalog excerpts

electrostatic innovations Top Class Remoistening WEBMOISTER 3000

Open the catalog to page 1

What do you actually need remoistening for? In the heatset web offset process the inks are dried with hot air. This is rapidly followed by a reduction in the water content of the paper, leading to considerable problems in the following processes. Electrostatic remoistening increases the water content in the paper after drying, returning to the level required.

Open the catalog to page 2

ellex electrostatic innovations advantages ng? Electrostatic remoistening not only noticeably improves the quality of printed matter, but also increases productivity throughout the entire process chain. Quality advantages y Eliminates buckling of perfect bound cross grain products y Prevents fibre breaking y No growing of pages y No climate waves (waviness) Remoistened signatures can be mixed with signatures printed in other printing processes without any problem. The signatures lie completely flat. Problems such as inner sheets dropping of stiched printed matter or creases at the folder...

Open the catalog to page 3

Can electrostatic remoistening be used with any heatset web offset press? Eltex remoistening systems can be used in all heatset web offset presses: small/wide presses up to 3.000 mm slow-/fast running presses from 6 m/s to 15 m/s light-weight/heavy grammages from 40 g to over 100 g/m² The WEBMOISTER 3000 meets every requirement.

Open the catalog to page 4

electrostatic innovations How does electrostatic remoistening actually work? Electric voltage and water – does it go together? Yes, it does! with electrostatic It is a commonly known fact that electrostatic charge attracts dust. This effect can be exploited with water on a running paper web by the controlled generation of high voltage. A fact known by the users of over 350 Eltex remoistening systems which have been installed worldwide. The paper web is charged via a charging bar – prior to remoistening. Pneumatic atomizing nozzles arranged in opposition spray water droplets which are...

Open the catalog to page 5

INNOVATIVE STRENGTH How does the WEBMOISTER 3000 differ from previous models? Since their launch in 1989, Eltex remoistening systems have undergone continuous optimization. The objective of this further development has been to immediately incorporate new findings to offer our customers the greatest advantages at the earliest possible date. Optimized technology by new nozzle concept Benefits > no waste water > reduced water specifications > wider web widths > lower operating costs

Open the catalog to page 6

electrostatic innovations The unit is operated via a new touch-screen remote control. The display provides the operator with information on the status, correct functioning and any possible faults of the system. The operator is carefully guided through the menu via key symbols with clearly allocated functions. Only the operating symbols actually required are displayed on the screen.

Open the catalog to page 7

electrostatic innovations Which elements make up the unit? The WEBMOISTER 3000 basically consists of three parts: > Remote control The remote control operates via a new touch-screen monitor integrated in the press control desk or mounted directly to the remoistening system. > Base frame The base frame includes the components of the system, the configuration of the bar, the nozzle bar and the paper web guide roller. > Control cabinet and supply modules The control cabinet is designed for direct mounting to the base frame and includes control elements, the high voltage generator and the water...

Open the catalog to page 8

Isn’t high voltage dangerous? The reliable Eltex charging bar is used to generate the high voltage field. The shockless bar guarantees an optimum field generation and field distribution. The Eltex high voltage generator supplies controlled and target-specific high voltage. This guarantees the highest degree of safety and optimal electrostatic field.

Open the catalog to page 9

electrostatic innovations Does the WEBMOISTER 3000 cause high operating costs? Just the opposite! The operating costs of the WEBMOISTER 3000 are lower than in all predecessor models. The energy consumption is negligible. The unit atomizes only the quantity of water which the paper needs; no waste water. Maintenance costs are extremely low.

Open the catalog to page 10

How much training will our printers need to operate the unit? The unit is very easy to operate; no need for complex training. In the basic version of the remote control, only the web width and the desired remoistening level need to be entered.

Open the catalog to page 11

electrostatic innovations How can I assess the effect of the WEBMOISTER 3000? Water amount in % Water content of paper during the printing process Printing units Chill rolls The best proof are satisfied customers who are pleased to receive top quality heatset products. In order to ensure customer satisfaction during the production process, we recommend making spot checks of the water content of the paper. The WEBMOISTER 3000 always sprays the amount needed. Moisture variations in paper are quite common and can be identified by regular measurements.

Open the catalog to page 12

Eltex remoistening units are used with the latest, extra-wide heatset web offset presses operating at highest production speeds, as well as on printing presses with normal web widths and speeds. Even if the print run is rather small and it is not worth operating at maximum speeds, the WEBMOISTER 3000 achieves a homogenous and linear remoistening. Today, over 120 printing houese worldwide already appreciate the advantages of Eltex remoistening systems. manroland Clausen & Bosse westermann druck jCOMORj Mohn media arvato LEYKAM tfT,LRHkT GAP offset alpine printing

Open the catalog to page 13

electrostatic innovations What can we do for you? You still have some questions? Don’t hesitate to ask your nearest Eltex consultant, the Product Manager for remoistening or contact the Eltex headquarters in Weil am Rhein. You may also see our website www.eltex.com for the latest information. The desire to know what our customers want and to find solutions for them is what drives us on. This is the basis of our expertise, enabling us to develop a wide range of pioneering electrostatic solutions and specific applications for you. Maintenance and support round off our range of services for...

Open the catalog to page 14All Eltex-Elektrostatik-GmbH catalogs and technical brochures

-

ELTEX CONNECTED CONTROL ECC

3 Pages

-

Technical information GNH63

56 Pages

-

Brochure ESA

15 Pages

-

Operating Manual TERRALIGHT

36 Pages

-

Brochure TERRALIGHT

3 Pages

-

Brochure Power Charger

5 Pages

-

POWER IONIZER - power supply

8 Pages

-

Technical information SDS

4 Pages

-

Brochure SDS

4 Pages

-

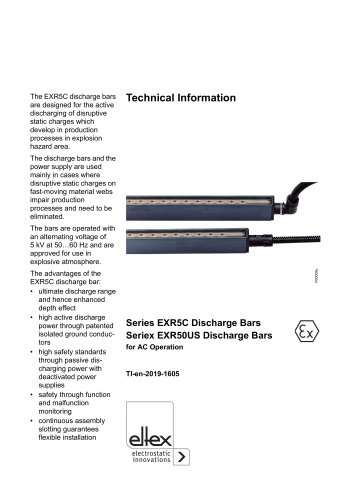

Technical information EXR5C

2 Pages

-

Technical information R45

2 Pages

-

Technical information RG52

4 Pages

-

Brochure flexION

4 Pages

-

Technical information CB

4 Pages

-

Brochure STATICJET RX22

3 Pages

-

Technical information RX3

4 Pages

-

Brochure RX3

3 Pages

-

Brochure BASIX

4 Pages

-

Technical information ES24

4 Pages

-

Technical information WM3000

12 Pages

-

Technical information SCC

3 Pages

-

Brochure Discharging

7 Pages

-

Brochure SCC

3 Pages

-

Brochure Ion Blower

5 Pages

-

Brochure Discharging

7 Pages

-

Technical information R55

8 Pages

-

Technical information DM1500

8 Pages

-

Brochure DM1500

2 Pages

-

Brochure RX11

3 Pages

-

Technical information R23ATR

8 Pages

-

Brochure Charging bars

5 Pages

-

Brochure BASIX

4 Pages

-

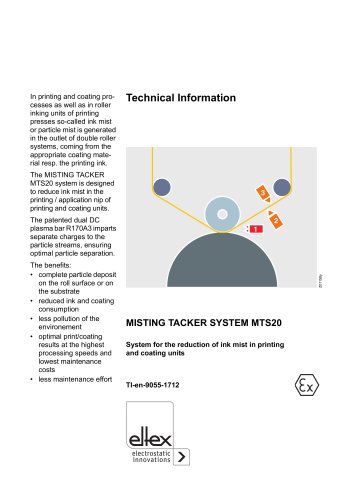

Technical information MTS

12 Pages

-

Brochure MTS

3 Pages

-

Brochure Cable reels

4 Pages

-

Brochure Grounding General

4 Pages

-

Technical information PGT120

4 Pages

-

Technical information GHH36

20 Pages

-

Brochure GHH36

2 Pages

-

Technical information ES53

4 Pages

-

Brochure Ground clamps

4 Pages

-

Brochure Grounding General

4 Pages

-

Technical information ES51

4 Pages

-

Technical information R55

8 Pages

-

Brochure Cable reels

4 Pages

-

Brochure Grounding General

4 Pages

-

Brochure Cable reels

4 Pages

-

Brochure Grounding General

4 Pages

-

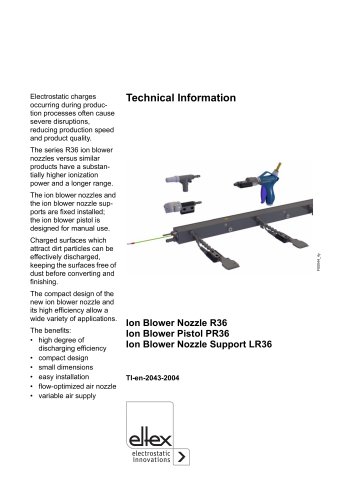

Technical information R36

8 Pages

-

Brochure Ion Blower

5 Pages

-

Brochure Terrapharm General

2 Pages

-

Brochure Grounding General

4 Pages

-

Brochure Terracap General

2 Pages

-

Brochure Grounding General

4 Pages

-

Technical information EM03

2 Pages

-

Brochure Charging bars

5 Pages

-

Brochure Ground clamps

4 Pages

-

Brochure Grounding General

4 Pages