Catalog excerpts

Steam Turbines and Gas Expanders

Open the catalog to page 1

■■ Introduction Proven Reliability and Efficiency Single stage and multistage designs Dependable, versatile turbomachinery is essential for today’s refinery, chemical process, and industrial applications. Due to the high cost of energy conversion and high feedstock prices, efficiency and dependability are primary considerations for equipment operators and plant owners. Elliott steam turbines and gas expanders provide proven reliability and high efficiencies which make them a key element of successful mechanical drive or power generation services. Elliott offers a complete line of steam...

Open the catalog to page 2

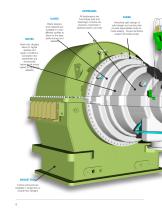

Casings A Solid Reputation – Performing under Pressure Elliott turbine casings are designed to perform under a wide array of operating conditions and can handle steam conditions to 2,000 psig (138 barg) and 1,005 F (541 C). The typical casing for an Elliott turbine consists of a cast high-pressure steam chest, an intermediate barrel section, and a separate exhaust casing. The barrel section is generally integral with the steam chest so that the vertical bolting joint is at one of the latter stages where internal pressures are very much reduced. The steam end, exhaust casing, nozzle ring,...

Open the catalog to page 3

Rotors Solid Forged Construction All Elliott multistage steam turbines are manufactured with solid forged rotor construction. Rotors are precisely machined from solid alloy steel forgings. An integrally forged rotor provides increased reliability particularly for high speed applications. The complete rotor assembly is dynamically balanced at operating speed and overspeed tested in a vacuum bunker to ensure safety in operation. High speed balancing can also reduce residual stresses and the effects of blade seating. Elliott also offers remote monitoring of the high speed balance testing,...

Open the catalog to page 4

Stationary Components Precision Design and Manufacturing Elliott’s nozzle rings and diaphragms are specifically designed and fabricated to handle the pressure, temperature and volume of the steam, the size of the turbine and the required pressure drop across the stage. The nozzles used in the first stage nozzle ring are cut from stainless steel. Steam passages are then precision milled into these nozzle blocks before they are welded together to form the nozzle ring. The nozzles in the intermediate pressure stages are formed from profiled stainless steel nozzle sections and inner and outer...

Open the catalog to page 5

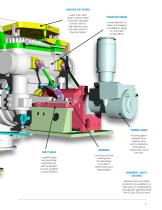

DIAPHRAGMS BLADES ROTORS Solid rotor designs allow for higher speeds and steam conditions. Complete rotor assemblies are dynamically balanced at actual speed for optimum reliability EXHAUST ENDS Turbine exhausts are available in single flow or double flow designs Blade designs and materials are available in many different profiles to allow for the best performance and reliability All diaphragms are horizontally split and diaphragm nozzles are precision machined in stainless steel to provide CASING Horizontal split casings of solid design and construction provide dependable metal-tometal...

Open the catalog to page 6

BAR/CAM LIFT VALVES Large multi-valve steam turbines utilize a bar/cam operated control valve for high efficiency and accurate control of flow and speed STEAM END DESIGN A wide selection of steam end designs is available in single or multi-valve configurations TURNING GEARS SHAFT SEALS Labyrinth seals are specifically engineered for each application and are available in many different BEARINGS Journal and thrust bearings are tilt-pad design for superior performance and dependability A turning gear is available when bearing span and/or operating temperature require slow-roll of the rotor...

Open the catalog to page 7

SINGLE-FLOW CONDENSING are highly economical and require the least steam for a given horsepower. Typically they are direct connected to a high speed compressor. Single Valve Turbines Designed for low to moderate power applications and available in two (2) frame sizes or in the Elliott YR turbine product line. These turbines are available up to 12,000 HP and 16,000 rpm. For higher speeds, Elliott offers the V model turbine. AUTOMATIC EXTRACTION and/or induction allows for controlled power and process steam pressure by automatically regulating the extraction/induction steam flows. DOUBLE-FLOW...

Open the catalog to page 8

Power Recovery Expanders The Leader in Reliability All of our stator vanes are individually replaceable for simple maintenance, and their placement is optimized to prevent “secondary erosion”, the cutting of the rotor blade platform and airfoils by the catalyst. Elliott’s superior aerodynamic design allows our TH expanders to maintain power recovery with proven reliability with minimal maintenance costs. Over the years, Elliott has brought many advances to refining processes including pioneering the Fluidized Catalytic Cracker (FCC) power recovery expander. Due to catalyst particulates in...

Open the catalog to page 9

Standard Designs Elliott YR Steam Turbines Single-valve, multi-stage designs Elliott’s product portfolio also includes several standardized turbine models for industrial and mechanical drive applications. Elliott YR steam turbine models are standardized and components are inventoried resulting in shorter lead times and quick turnarounds. Because of their flexibility, thousands of YR turbines are driving pumps, compressors, fans, blowers, generators, sugar mill tandems, cane shredders, paper machine line shafts and many other industrial plant applications. For improved steam consumption,...

Open the catalog to page 10

Tri-Sen TSx Control System Elliott has partnered with Tri-Sen to offer the TSx programmable turbomachinery control system for Elliott equipment. The TSx is uniquely suited to meet the needs of critical turbomachinery control applications in oil & gas, power, refining, chemicals, or any other industry where unmatched performance and flexibility is demanded. The TSx architecture is completely scalable from the simplest single chassis systems to the most complex systems with up to sixteen chassis per note without any degradation in performance. The TSx controller boasts SIL3 reliability,...

Open the catalog to page 11All Elliott Group catalogs and technical brochures

-

Elliott Tilting-Pad Bearings

4 Pages

-

YR Steam Turbines

8 Pages

-

Elliott Packaging Solutions

8 Pages

Archived catalogs

-

Elliott Bearing Isolators

2 Pages

-

Elliott Digital Governors

2 Pages

-

Elliott Turbine Generators

8 Pages

-

Elliott Steam Turbines

12 Pages

-

Elliott Compressors

12 Pages