Website:

Elettronica Todescato

Website:

Elettronica Todescato

Catalog excerpts

OPEN PACKAGE AND PLACE ALL ITEMS ON A WORKING BENCH TABLE. The package contains: burner tips; user manual; quick start guide; DVD guide; USB tutorial guide; spare fuse; plastic funnel; torch(es); fire proof plastic hose; power cord. For a better understanding, Elettronica Todescato recommends to take vision of our DVD and/or USB Key guide, and to simultaneously consult the present manual. Make sure that the switch is turn on “O” (OFF). Then, plug the power cord / cable into the machine and into the electrical outlet making sure the voltage is correct. PREPARE THE ELECTROLYTE SOLUTION...

Open the catalog to page 2

5,340 liters of distilled or demineralized water needed to fill the tank. Mix with 2160 grams of potassium hydroxide (KOH). Let the chemical components cool down for 10 to 15 minutes or more. In appendix 1, there are Conversion Tables that can assist you in the amounts needed for different units of measure. UNSCREW THE SAFETY CAP ON TOP OF THE MACHINE. Step 4 Turn the switch into the down position ( “=” ) to refill, this will enable the operator to check the level of demineralized water.

Open the catalog to page 3

Green light is “on”, indicating the machine is connected to the electricity. (pic 1) Yellow light is “on”, initially indicating the internal tank level is empty and needs to be filled, or the water level is below normal during daily usage and there is need to add more water. (see picture below) Red light is, “off”, indicating that the internal tank needs to be filled. (picture # 1) IMPORTANT NOTICE: The electrolyte solution’s lifetime is of one year. It must be poured when: 1- Using unit for the first time. 2- When solution has previously been poured through contaminated or dirty funnel. 3-...

Open the catalog to page 4

POUR ELECTROLYTE SOLUTION After the electrolyte solution has cooled off, pour the solution into the internal tank (slowly) using a funnel, until the Red-light indicator comes on, (pic. 2) indicating the internal tank is properly filled. At the same time, the Yellow light will turn “off”, indicating that the tank is being filled and has reached above the minimum level required. Stop pouring the solution, as soon as the red light comes on. When the red light comes on, stop pouring the demineralized water, in order to avoid over filling the tank. (This is IMPORTANT: DO NOT OVERFILL). Then...

Open the catalog to page 5

FLUX (deoxidizer) Methyl Alcohol ( 1 liter ) + Boric Acid ( 15 – 20 grams ) sec . 4.5 in the USER MANUAL), contains the procedure and safety precautions to follow. HERMETIC SEAL Step 7 BOOSTER TANK FILLING Take the un-attached booster tank in hand, start pouring the deoxidizer in the booster tank by placing your index on the hole in the center of the booster tank to avoid filing the interior chamber. (picture # 3) (picture # 4) Fill to the maximum level indicated on the outside of the booster tank or pour MAX ½ liter (500 cc) of deoxidizer (see pic. # 4). (DO NOT OVER-FILL)

Open the catalog to page 6

STEP 8. BOOSTER TANK INSTALLATION To mount the booster tank after having it filled with the flux (deoxidized), tighten the handle knob making sure to not over screwing in order to preserve the gaskets and the internal thread of the booster tank. (BOOSTER TANK HANDLE KNOB) NOTE : For daily use and refill, refer to the section called “ ATTENTION ! (page 10).

Open the catalog to page 7

Step 9 a. NOTE: to connect the hoses properly, see picture BELOW. Prepare the special torch making sure the hose is fitted (#16) to its fitting and the nozzle or burner tip (refer to Table 2 or Table 2A) is selected and fitted (#11). SPECIAL TORCH

Open the catalog to page 8

Step 9 b. One Special Torch or Standard Torch (optional). Connect the hose to the GAS OUTLET fitting, then select the nozzle or burner tip (refer to Table2 or Table 2A). NOTE: TO CONNECT HE HOSES TO THE FITTINGS, UNSCREW THE FERRULE. See Picture Below. Then insert the plastic hose to the fitting, tightening the ferrule to ensure a proper and secure connection. NOTE: For daily use and refill, refer to the section called “ ATTENTION ! “ After mounting the booster tank, select the burner tip you will use

Open the catalog to page 9

HOW TO ADJUST THE POWER ACCORDING TO NEEDLE TIP SIZE: Standard torch How to adjust the Power Control Knob Simultaneously check the gas supply indicator, according to Min and Max L/h (see Table 2) Then check the minimum and maximum settings for the power control knob (picture # 5) according to the diameter of the burner tip. Failure to follow the suggested in/max settings will result in melted or fused burner tips (picture # 7)

Open the catalog to page 10

Select your chosen burner tip or nozzle and push and screw in to place at the base of the torch. (picture # 6 and # 8).

Open the catalog to page 11

Step 10 IMPORTANT: Before turning on the machine set the power control knob to zero (see picture below). Unscrew the ferrule refer to the user manual (Fig. 1 # 66).

Open the catalog to page 12

(picture # 8) Then insert the rubber hose into the fitting, tightening the ferrule to ensure a proper and secure. (See above pic. # 8) Step 11 Switch the machine on by turning the switch up into “-“. After turning the machine on, a couple of minutes later, gas production will start. Wait until you hear the gas being discharged and flow easily from the burner tip

Open the catalog to page 13

Step 12 Wait to the gas to exit from the burner tip (approximately two/three minutes or more), then light the flame with a lighter or electronic igniter. If the flame is too weak move on to the next burner tip on table two (2). See picture below. Step 13 To turn off the machine switch the flame off by pushing the base of the torch (as you do with a pen), then ultimate the procedure by turning the switch to “0”. Always shut the flame OFF, before turning machine off. Do not turn the machine “off” while the flame is lit. Always, turn OFF the flame from the torch, before shutting down the...

Open the catalog to page 14

IMPORTANT NOTE: For the first startup of our ET systems, or for the yearly maintenance (once every year), the machine must be filled or re-filled with electrolyte solution. For the daily re-fill it is mandatory to pour only demineralized (or distilled) water inside the electrolyte tank. Pouring daily electrolyte solution will cause a crystallization inside the tank and consequent obstructions of machine’s hoses, potentially causing a general malfunction.

Open the catalog to page 15All Elettronica Todescato catalogs and technical brochures

-

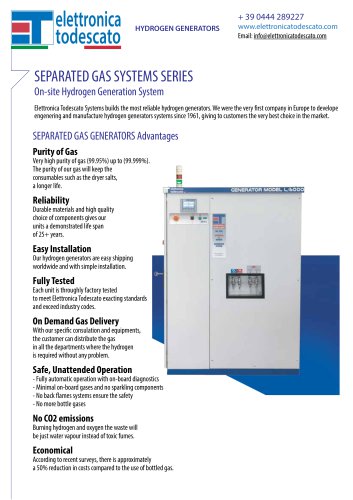

SEPARATED GAS SYSTEMS SERIES

2 Pages

-

HYDROGEN & OXYGEN GENERATORS

2 Pages